Wire rope is a fundamental component in industries such as construction, marine, mining, and heavy manufacturing. Its combination of strength, flexibility, and durability makes it indispensable for lifting, hoisting, towing, and securing heavy loads. Understanding wire rope involves knowing its construction types, materials, specifications, applications, maintenance standards, and compliance with international standards. This comprehensive guide provides a detailed overview suitable for engineers, procurement specialists, and rigging professionals.

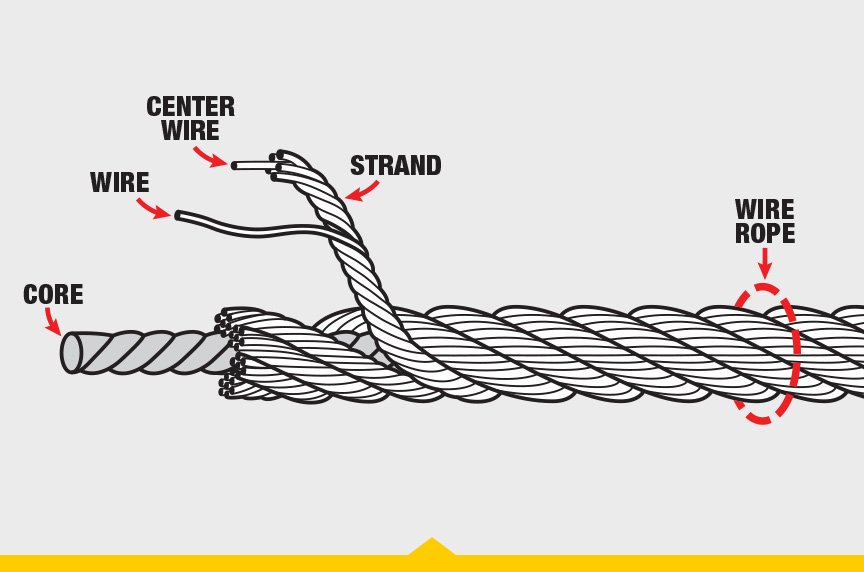

Wire rope is a mechanical assembly made of multiple strands of metal wires twisted together to form a strong and flexible rope. Unlike chains or single cables, wire ropes offer both load-bearing capacity and flexibility, allowing them to bend over pulleys, drums, or sheaves without compromising structural integrity.

Wire ropes are widely used to transmit force, provide mechanical support, and lift or tow heavy objects. They are essential in cranes, elevators, shipping operations, offshore rigs, and mining equipment.

The first modern wire rope was invented by Wilhelm Albert, a German mining engineer, in the 1830s. Traditional hemp ropes used in mining were prone to wear and breakage under heavy loads. Albert’s rope, made of twisted steel wires, offered higher tensile strength and durability, revolutionizing mining operations.

Over time, wire rope manufacturing evolved to include galvanized and coated ropes, rotation-resistant designs, and specialized industrial applications, making wire rope an engineering standard across industries.

Wire rope construction determines its strength, flexibility, fatigue resistance, and suitability for specific applications. Modern wire ropes are classified based on structure and functional design:

Round strand wire ropes are made of wires twisted into circular strands, which are then twisted around a core. These ropes offer good flexibility and moderate strength, making them suitable for general lifting and rigging tasks. They are easy to handle and widely used in cranes, hoists, and elevators.

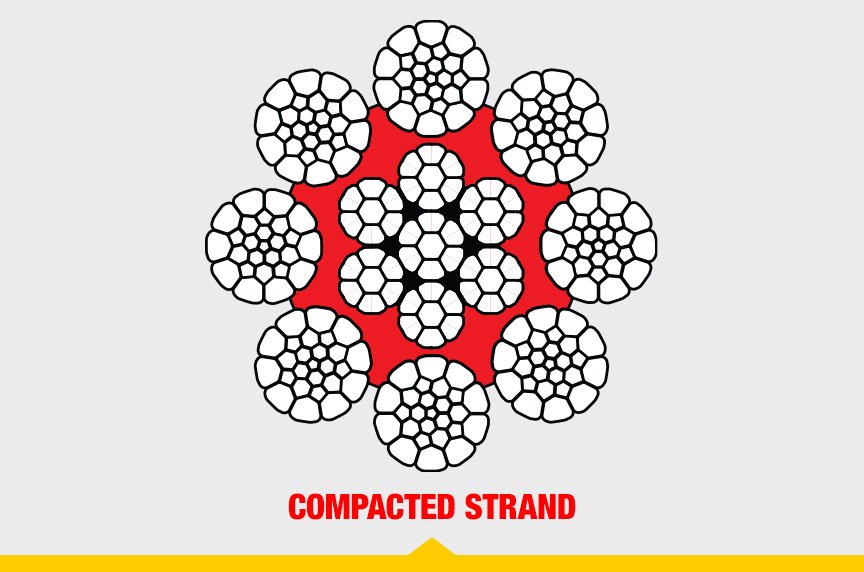

Compacted wire ropes are mechanically compressed after twisting, which reduces the rope diameter and increases density. This process improves:

Tensile strength

Wear resistance

Abrasion resistance

Compacted ropes are ideal for long-term heavy-duty lifting, mining, and offshore operations, where rope life and durability are critical.

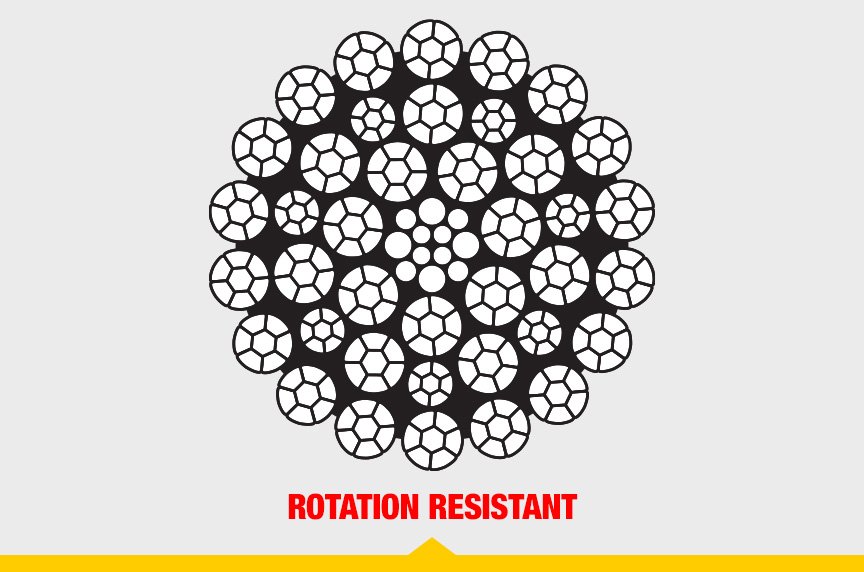

Rotation-resistant ropes are specially designed so that the rope does not spin or rotate under load. This is achieved by using specific strand constructions and lay directions. These ropes are particularly suitable for hoist ropes in tower cranes, elevators, and lifting equipment, where load rotation could be dangerous.

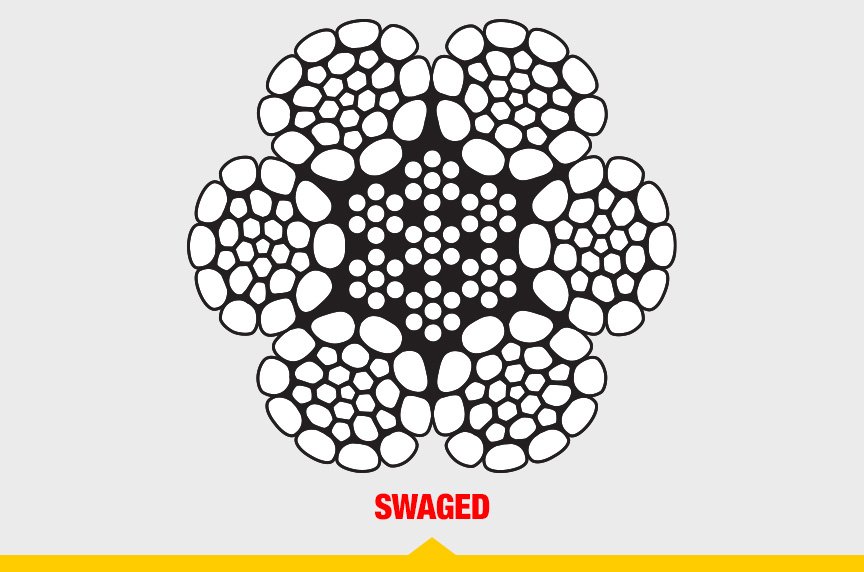

Swaged wire ropes are produced by mechanically compressing metal fittings or terminals onto the rope to form permanent ends. Swaging ensures secure connections for lifting, anchoring, or towing applications. These ropes are often used in structural rigging, maritime mooring, and heavy lifting.

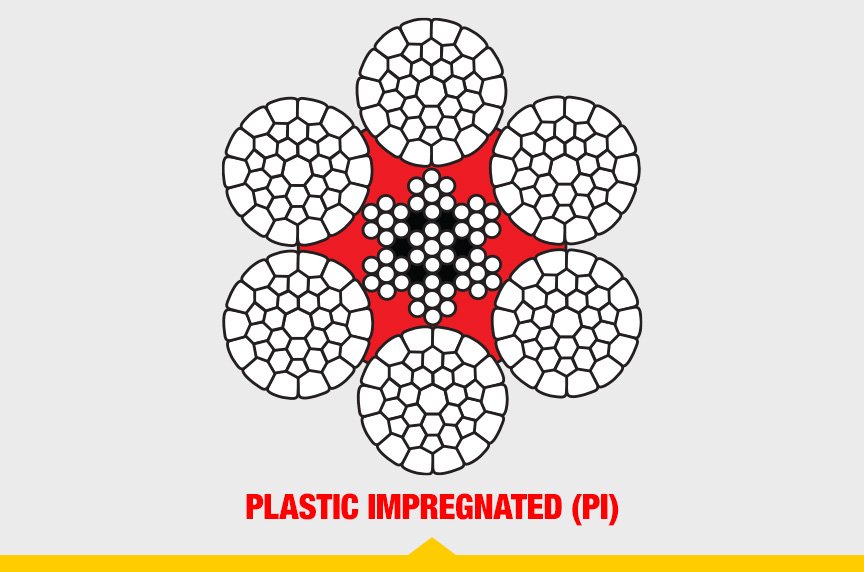

Plastic Impregnated (PI) wire ropes have steel strands embedded in a thermoplastic coating, typically polyurethane or nylon. This construction provides:

Corrosion resistance

Improved flexibility

Resistance to abrasion

PI wire ropes are widely used in offshore cranes, marine applications, and environments with high moisture or chemical exposure. They are low-maintenance and offer a longer service life than uncoated ropes.

Plastic coated wire ropes are fully covered with an external plastic sheath over the steel strands. Unlike PI ropes (where plastic penetrates the rope core), plastic-coated ropes have a smooth outer layer that:

Protects against corrosion and weather

Reduces abrasion and rope wear

Provides safer handling by reducing sharp wire exposure

Improves aesthetics and visibility in outdoor or marine applications

Plastic-coated wire ropes are commonly used in marine, recreational, construction, and industrial lifting applications, especially where ropes are exposed to moisture, chemicals, or frequent handling.

Wire rope materials are selected based on strength, corrosion resistance, and operational environment.

High strength and cost-effective; widely used for general lifting, rigging, and construction. Can be galvanized for outdoor applications.

Resistant to corrosion, suitable for marine, offshore, and chemical industries. Slightly lower tensile strength than carbon steel but superior longevity in corrosive conditions.

Steel wires coated with zinc to prevent corrosion. Common in outdoor, marine, and high-humidity environments.

Lubrication and polymer coatings reduce friction, wear, and corrosion, increasing operational life. Includes:

Plastic-impregnated ropes (PI) – Plastic penetrates the rope core

Plastic-coated ropes – Full outer sheath protects steel strands

Lubrication: oil-based, grease-based, or synthetic

Correct specification ensures safety, performance, and longevity.

Includes core and strands. Proper diameter selection ensures the rope can safely carry the intended load.

Maximum load the rope can handle before failure. High-tensile ropes are used for heavy-duty lifting and industrial operations.

The controlled load at which the rope fails. Safety factors are applied in operational scenarios.

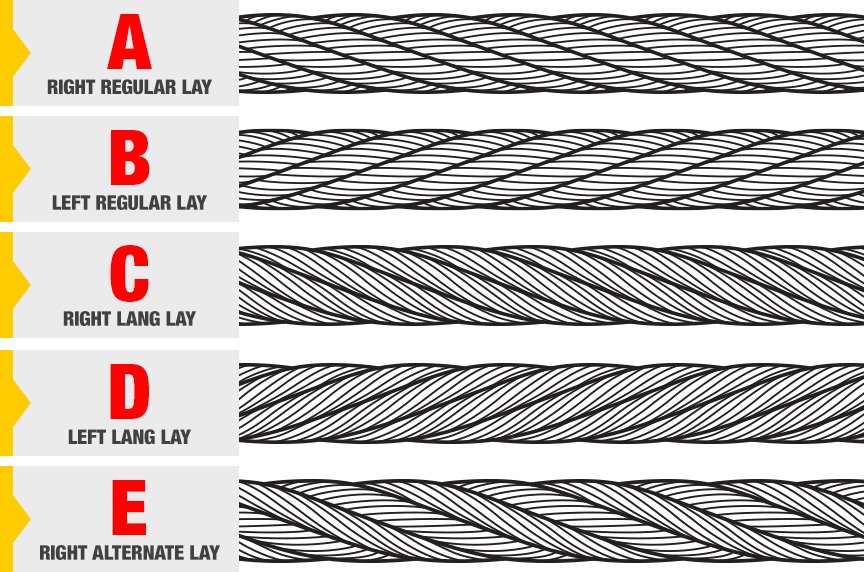

Right-hand lay – Most common; resists unwinding.

Left-hand lay – Used for specialized hoist or rotating systems.

Fiber Core (FC): Flexible, absorbs shock, lightweight.

Independent Wire Rope Core (IWRC): Provides maximum strength and durability.

Strand Core (SC): Medium-duty, moderate flexibility.

Hoist Ropes – For lifting equipment in cranes and elevators.

Luffing Ropes – Tower cranes and adjustable jib cranes.

Marine Ropes – Mooring, towing, and offshore rigging.

Mining Ropes – Heavy-duty lifting and hauling in mines.

Rotation-Resistant Ropes – Prevent load rotation during lifting.

Plastic-Impregnated and Plastic-Coated Ropes – Marine, outdoor, and chemical-resistant applications.

Wire ropes are widely applied in industries requiring strength, flexibility, and reliability.

Used in tower cranes, hoists, elevators, and concrete lifting, with emphasis on fatigue resistance and load ratings.

Used for mooring, towing, and offshore operations. Galvanized, PI, or plastic-coated ropes ensure longevity in saltwater environments.

Supports hoists, winches, draglines, and conveyors under extreme loads and abrasive conditions.

Used in material handling, overhead cranes, elevators, and conveyors.

Essential for lifting, towing, and rigging, requiring corrosion resistance and fatigue strength.

Proper maintenance ensures safety and extended service life.

Check for broken wires, corrosion, abrasion, kinks, or deformation.

Reduces friction and corrosion; applied during manufacturing or routine maintenance.

Proper storage, spooling, and handling prevent kinks, crushing, and excessive bending.

Inspect swaged fittings, clamps, and sockets for secure attachment.

Wire ropes must comply with international standards:

EN 12385 – Steel wire ropes for general engineering and lifting purposes (Parts 1–11).

EN 13411 – Wire rope terminations (sockets, swaged fittings).

EN 13414 – Wire rope slings; safety requirements for lifting operations.

ISO 2408 – Steel wire ropes for general engineering purposes.

DIN 3060 / 3061 – Wire rope manufacturing and testing specifications.

API and ABS standards – Offshore and marine operation ropes.

OSHA 1910.184 – Safety requirements for slings and wire ropes in lifting.

Compliance with EN, ISO, and other international standards ensures safety, reliability, and regulatory acceptance.

Selection depends on:

Load requirements – Maximum working load and safety factor.

Environmental conditions – Corrosion, moisture, temperature, chemical exposure.

Flexibility – Ability to bend over sheaves, drums, or pulleys.

Rope life – Expected operational lifespan.

Construction type – Round strand, compacted, rotation-resistant, swaged, PI, or plastic-coated.

Standards compliance – EN, ISO, DIN, or other regulatory standards.

Proper selection ensures safe, efficient, and cost-effective operation.

Wire ropes may fail due to:

Broken wires – Fatigue, bending, or corrosion.

Kinking or crushing – Improper handling or spooling.

Abrasion – Contact with sharp or rough surfaces.

Corrosion – Exposure to moisture or chemicals without protection.

Routine inspections and correct handling prevent most issues.

Recent advances include:

High-tensile steel ropes – Stronger and lighter.

Plastic-impregnated and plastic-coated ropes – Reduced corrosion and maintenance.

Rotation-resistant designs – Safer hoisting.

Customized constructions – For offshore, mining, and industrial applications.

Wire rope remains essential in modern industry, combining strength, flexibility, and reliability. Understanding construction types (round strand, compacted, rotation-resistant, swaged, PI, plastic-coated), materials, applications, maintenance, and EN/ISO/DIN standards is crucial for safe and efficient operations.

From 19th-century mining origins to offshore and mega-construction applications, wire rope continues to evolve with engineering innovation, meeting the most demanding industrial challenges.

Kaiyuan road 36,Chunkou,Liuyang, Hunan,China.

info@steelwireropes.cn

admin@steelwireropes.cn

Phone : +86 15573139663

WhatsApp : +86 15573139663

Expert guidance on wire rope specifications and applications

WhatsApp us

Free samples, product catalog, and expert consultation available.