Are you worried about rope spin and stability on your high-lift tower crane? An unstable rope is not just inefficient; it’s a serious safety hazard. We have a specialized solution.

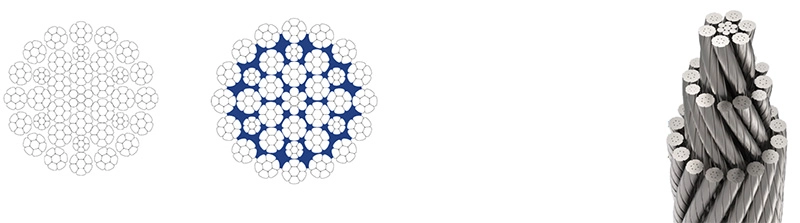

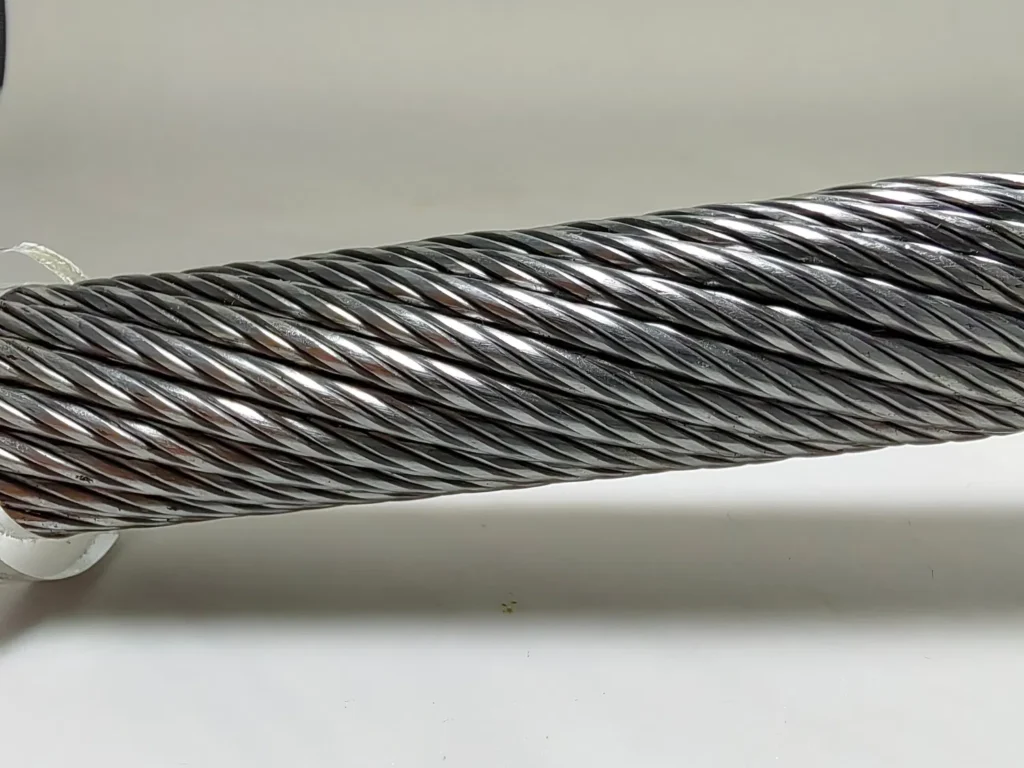

The 35WxK7 steel wire rope is a premium, rotation-resistant rope. Its unique multi-strand, compacted design provides superior stability, high breaking strength, and excellent flexibility, making it the ideal choice for modern tower crane hosting operations.

I’ve been in the wire rope business for a long time. I once met a project manager who was constantly dealing with load spin on a high-rise construction site. It was dangerous and slowed down his entire project. After we helped him switch to a 35WxK7 rope, his problems disappeared. Let’s dive into why this specific rope construction is such a game-changer.

What Makes The 35WxK7 Construction So Rotation-Resistant?

You often hear the term “rotation-resistant,” but what does it really mean for your crane? It is all about a clever internal design that fights the rope’s natural desire to twist under load.

The 35WxK7 construction has multiple layers of strands. The outer strands are laid in the opposite direction to the inner strands. This design creates a counter-torque effect that cancels out rotational forces, keeping the load stable.

Let’s explore this design in more detail. A standard wire rope, like a 6×19, has all its strands laid in the same direction. When you lift a heavy load, all those strands try to unwind together. This is what causes the hook and load to spin. For many applications, this is not a problem. But for a tower crane lifting materials hundreds of feet in the air, spinning is unacceptable.

The 35WxK7 is part of a family of “non-rotating” or, more accurately, “rotation-resistant” ropes. The magic is in the opposing forces.

Dive Deeper: How Opposing Layers Work

The Principle of Counter-Twist

Imagine holding two rubber bands. If you twist both of them to the right and let go, they will spin wildly. Now, imagine you have a core rubber band twisted to the right, and you wrap another one around it, twisted to the left. When you let them go, the forces work against each other. They largely cancel out, and the whole assembly stays much more stable. A 35WxK7 wire rope works on this exact principle, but with high-strength steel wires.

- Inner Strands: The inner layers of strands are twisted in one direction (for example, to the right).

- Outer Strands: The outer layer of strands is twisted in the opposite direction (to the left).

When the rope is tensioned, the outer strands want to twist one way, and the inner strands want to twist the other. This internal battle for dominance results in a very stable rope that resists the tendency to rotate.

Rotation Resistance Comparison

Not all ropes are created equal when it comes to stability. The level of rotation resistance is a critical safety and performance factor.

| Rope Construction | Rotation Characteristic | Common Use Case |

|---|---|---|

| 35WxK7 | Excellent Resistance | Main Hoist on Tower & Mobile Cranes |

| 19×7 | Good Resistance | Auxiliary Hoists, General Lifting |

| 6×36 | Low Resistance (Prone to spin) | Winches, Static Lines |

As you can see, the 35WxK7 is engineered specifically for the most demanding applications where load stability is paramount.

Are All 35WxK7 Ropes Created Equal?

A rope is much more than its construction type. The quality of the steel, the manufacturing process, and a few key features determine its real-world strength and service life.

No, they are not created equal. Critical differences lie in the steel tensile strength, the surface finish (galvanized or not), and whether the strands are compacted. These factors directly impact the rope’s breaking load and resistance to wear.

When you are sourcing a critical component like a crane rope, the details matter. Just asking for a “35WxK7 rope” is not enough. You need to understand the specifications to ensure you get a product that is safe and will last. At our Aulone factory, we focus on these details on our 10 production lines.

Dive Deeper: Key Quality Specifications

Steel Tensile Strength

This is a measure of how much force the steel wire can withstand before breaking. It’s usually measured in Newtons per square millimeter (N/mm²).

- 1960 N/mm²: A common and high-strength grade, suitable for many applications.

- 2160 N/mm²: An Extra High Tensile (EHT) grade. This rope is significantly stronger than a 1960-grade rope of the same diameter. This can be useful for increasing a crane’s safety factor or when a smaller diameter rope is needed for a specific drum.

Choosing a higher tensile strength means a higher Minimum Breaking Load (MBL) for the same size rope.

The Power of Compaction

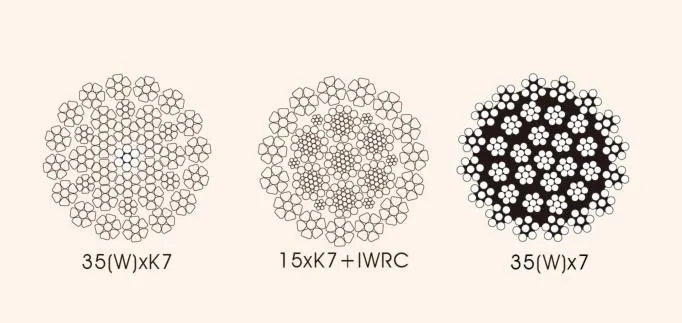

The “K” in 35WxK7 stands for “kompakt” in German, which means compacted. This is a crucial manufacturing step.

- Standard Strands: Round wires are spun into a round strand. There are small gaps between each wire.

- Compacted Strands: After the strand is made, it is passed through a special die or rollers that compress it. This flattens the outer wires and reduces a lot of the empty space inside.

Why is compaction so important?

| Benefit of Compaction | Explanation |

|---|---|

| Increased Strength | Compaction increases the metallic cross-sectional area. More steel in the same diameter means a stronger rope. |

| Improved Wear Resistance | The smoother, flatter outer surface has more contact with sheaves and drums, spreading wear over a larger area. This reduces abrasion. |

| Better Drum Spooling | The smooth, stable profile of a compacted rope helps it spool evenly onto the crane drum, reducing the risk of crushing and damage. |

| Higher Density | The rope is more resistant to being crushed or flattened under pressure. |

Example Breaking Loads

Here is a table showing how tensile strength affects the Minimum Breaking Load (MBL) for our compacted 35WxK7 ropes. These values comply with EN12385-4.

Technical Parameters

| Diameter | Approx.weight(kg/100m) | Tensile strength (MPa) | ||

| (mm) | 1770 | 1960 | 2160 | |

| Minimum breaking load (kN) | ||||

| 8 | 33 | 51 | 56 | 62 |

| 9 | 41 | 65 | 71 | 79 |

| 10 | 51 | 80 | 88 | 97 |

| 11 | 62 | 96 | 107 | 118 |

| 12 | 73 | 115 | 127 | 140 |

| 13 | 86 | 135 | 149 | 164 |

| 14 | 100 | 156 | 173 | 191 |

| 15 | 115 | 179 | 198 | 219 |

| 16 | 131 | 204 | 226 | 249 |

| 17 | 147 | 230 | 255 | 281 |

| 18 | 165 | 258 | 286 | 315 |

| 19 | 184 | 288 | 318 | 351 |

| 20 | 204 | 319 | 353 | 389 |

| 21 | 225 | 351 | 389 | 429 |

| 22 | 247 | 386 | 427 | 470 |

| 23 | 270 | 421 | 467 | 514 |

| 24 | 294 | 459 | 508 | 560 |

| 25 | 319 | 498 | 551 | 608 |

| 26 | 345 | 538 | 596 | 657 |

| 27 | 372 | 581 | 643 | 709 |

| 28 | 400 | 624 | 691 | 762 |

| 29 | 429 | 670 | 742 | 817 |

| 30 | 459 | 717 | 794 | 875 |

| 31 | 490 | 765 | 848 | 934 |

| 32 | 522 | 816 | 903 | 995 |

| 35 | 625 | 976 | 1080 | 1191 |

| 36 | 661 | 1032 | 1143 | 1260 |

| 39 | 776 | 1211 | 1342 | 1478 |

| 40 | 816 | 1274 | 1411 | 1555 |

Why Should You Consider a Plastic Impregnated (PI) 35WxK7 Rope?

Let us talk about a powerful upgrade that can significantly extend your rope’s service life. We can fill the internal space of the wire rope with a specialized, stable plastic.

A plastic-impregnated core seals factory lubricant inside the rope and blocks moisture and dirt from getting in. This drastically reduces internal friction and corrosion, leading to a much longer and safer service life.

A standard wire rope is essentially a complex machine with many moving parts. The wires and strands rub against each other every time the rope bends or straightens. This internal friction is a major cause of wear. While grease helps, Plastic Impregnation (PI) takes protection to the next level.

Dive Deeper: The Advantages of a Plastic Core

Benefit 1: Permanent Internal Lubrication

A wire rope is lubricated at the factory. But over time, this grease can dry out, get squeezed out under pressure, or be washed away by rain. Our plastic impregnation process injects plastic into the rope, filling the voids between the strands. This locks the lubricant in place for the entire life of therope. You never have to worry about the rope’s core drying out.

Benefit 2: Blocking Corrosion From the Inside

The most dangerous corrosion is the kind you cannot see. Moisture can get deep inside a rope and cause the inner wires to rust and fail, even if the outside looks fine. The plastic layer creates an impermeable barrier. It prevents water, salt, dust, and chemicals from reaching the core, effectively stopping internal corrosion before it can start. This is especially vital for cranes operating in harsh environments, like coastal areas or industrial zones. We export many of these ropes to clients in Singapore, Saudi Arabia, and Vietnam for this very reason.

Benefit 3: Enhancing Structural Integrity

The plastic core acts as a cushion for the strands.

- Reduces Internal Wear: It prevents steel-on-steel contact between the inner and outer strands, reducing friction and abrasive wear.

- Improves Shape: The plastic provides support, helping the rope maintain its round profile and preventing it from flattening or crushing on the drum.

Comparison: PI vs. Standard IWRC (Independent Wire Rope Core)

| Feature | Plastic Impregnated (PI) Rope | Standard Steel Core (IWRC) Rope |

|---|---|---|

| Internal Friction | Drastically Reduced | High (metal-on-metal contact) |

| Internal Corrosion | Highly Resistant | Susceptible to moisture intrusion |

| Lubricant Retention | Excellent (sealed in) | Fair (can be lost over time) |

| Service Life | Significantly Longer | Standard |

| Initial Cost | Higher | Lower |

While a PI rope has a higher upfront cost, its greatly extended service life and reduced maintenance needs often make it the more economical choice in the long run.

What Certifications Guarantee Your 35WxK7 Rope is Safe?

You need absolute confidence that your tower crane rope is safe and meets global standards. Certificates are not just paperwork; they are your proof of quality and your guarantee of safety.

Always look for compliance with EN12385-4, the specific European standard for crane ropes. For total assurance, ask for third-party certificates from bodies like ABS, DNV, RMRS, or BV, which verify the rope’s quality independently.

As a manufacturer, we see a wide range of quality in the market. Some ropes are sold with only a basic factory test report. For a critical application like a tower crane, this is not enough. Serious buyers, like our partners in Australia and Canada, demand comprehensive proof of quality. They know that a trusted certificate is the best way to manage risk.

Dive Deeper: Understanding Rope Certification

The EN12385-4 Standard

This is one of the most important standards in our industry. It is not just a general guideline. It is a detailed European Norm that specifies the requirements for steel wire ropes used in cranes.

What EN12385-4 Covers

- Materials and manufacturing processes

- Minimum wire tensile strengths

- Rope dimensions and tolerances

- The exact procedures for testing breaking force

- Information that must be provided by the manufacturer

If a rope is certified to EN12385-4, you know it was made and tested to a high, internationally recognized benchmark.

The Power of Third-Party Verification

A manufacturer’s own test report is good, but a certificate from a respected third-party classification society is even better. Companies like:

ABS(American Bureau of Shipping)DNV(Det Norske Veritas)RMRS(Russian Maritime Register of Shipping)BV(Bureau Veritas)CEfor European conformity

These organizations act as independent inspectors. When a client needs it, we can have an inspector from one of these societies come to our factory. They will witness the production and testing of the rope. They will then issue their own certificate. This gives the buyer another layer of confidence that the product meets all specifications.

Key Information on a Mill Test Certificate

When you receive your rope, it should come with a mill test certificate. This document is the rope’s “birth certificate.” You should check it for the following key details:

Critical Certificate Data

- Manufacturer:

Aulone - Standard:

EN12385-4 - Rope Details: e.g.,

35WxK7 - IWRC, Compacted, RHOL - Nominal Diameter: e.g.,

16 mm - Tensile Grade: e.g.,

2160 N/mm² - Surface:

UngalvanizedorGalvanized - Minimum Breaking Load (MBL): The calculated MBL based on the standard.

- Actual Breaking Load (ABL): The force at which the sample actually broke in testing. This must be higher than the MBL.

- Traceability: A unique rope or batch number that links the physical rope to this specific certificate.

Always keep this certificate with your crane’s maintenance records. It is essential for safety audits and inspections.

Conclusion

The 35WxK7 wire rope is a premium choice for tower cranes. Its stability, strength, and durability provide the safety and performance needed for demanding high-rise lifting operations.