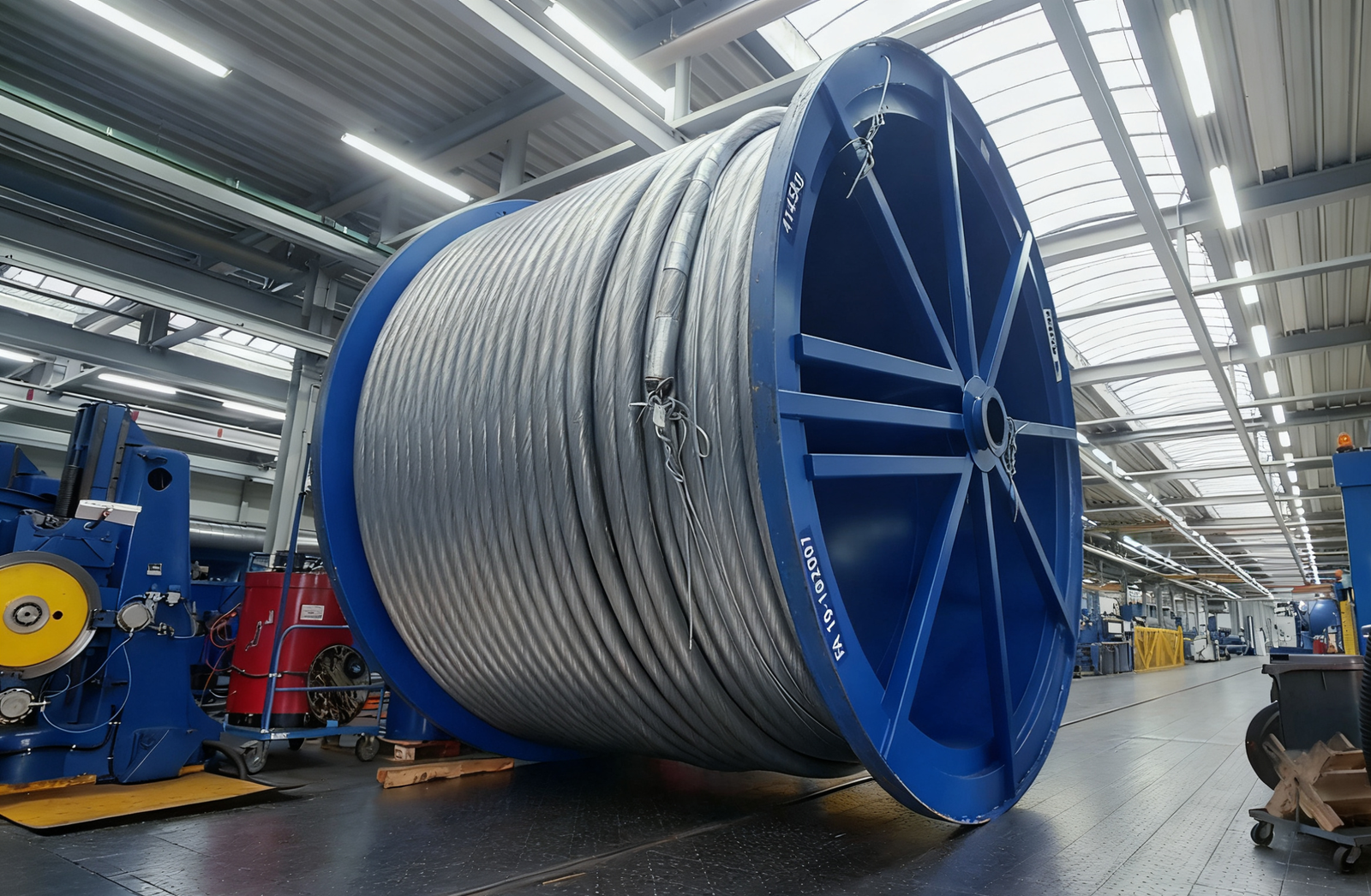

Mining shafts demand precise guidance. Conveyances slipping or rotating cause accidents. I discovered Aulone guide ropes solve this problem reliably.

Aulone guide ropes keep underground conveyances steady at speeds up to 20m/sec. They provide safe, efficient, and cost-effective solutions for mining operations.

I still remember the first time a conveyance ran smoothly along the shaft. It proved the true value of using high-quality guide ropes.

How Do Aulone Full Lock Guide Ropes Support Mining Operations?

Mining shafts require ropes that resist wear, maintain position, and carry heavy loads. Full Lock ropes meet these exact needs.

Aulone Full Lock guide ropes provide maximum breaking load, excellent wear resistance, and long service life, ideal for high-demand mining environments.

Full Lock Guide Ropes Features and Benefits

- Applications: Guide ropes and rubbing ropes for heavy-duty conveyances

- Advantages:

- Maximum breaking load ensures safety

- Excellent wear and abrasion resistance

- Long service life reduces downtime

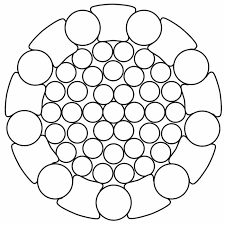

- Features:

| Feature | Specification |

|———|—————|

| Compaction | Compacted for enhanced stability |

| Core | IWRC (Independent Wire Rope Core) |

| Steel Grades | 1770, 1860, 1960 N/mm² |

| Lay Type | Langs lay or Regular lay |

| Lay Direction | RH (Right Hand) or LH (Left Hand) |

| Finish | Bright or Galvanized |

Full Lock ropes handle friction from guide sheaves and high-speed conveyances. I have seen installations last years longer than ordinary ropes. Maintenance and downtime were significantly reduced.

What Advantages Do Half Lock Guide Ropes Offer in Mining?

Sometimes mining operations need ropes with reduced stretch, corrosion resistance, and high strength. Half Lock ropes are built for this balance.

Aulone Half Lock guide ropes combine high strength, low rotation, optimized wear resistance, and extended service life, perfect for underground conveyances.

Half Lock Guide Ropes Specifications and Applications

- Applications: Guide and rubbing ropes for shafts and material transport

- Advantages:

- Optimized strength-to-weight ratio

- Tailored lubrication for smooth operation

- Low rotation reduces twisting

- Long service life minimizes replacements

- Supports largest available wire diameters

- Features:

| Feature | Specification |

|———|—————|

| Compaction | Compacted for performance stability |

| Core | IWRC |

| Steel Grades | 1770, 1860, 1960 N/mm² |

| Lay Type | Langs lay or Regular lay |

| Lay Direction | RH or LH |

| Finish | Bright or Galvanized |

Why Are Aulone Guide Ropes Cost-Effective for Mining?

Mining companies aim to reduce downtime and maintenance costs. Guide ropes play a key role in achieving this.

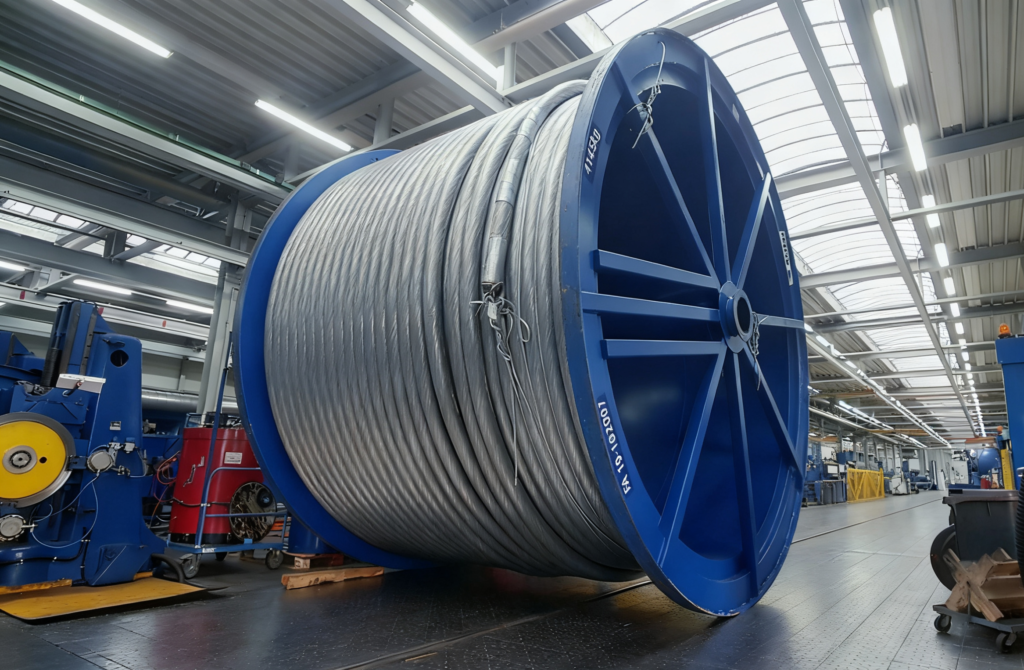

Aulone guide ropes lower maintenance needs, improve conveyance safety, and provide consistent performance, delivering strong value for mining operations.

Cost-Effectiveness Explained

- Readily available: Quick supply prevents project delays

- Consistent performance: Reliable strength reduces failures

- Wear resistance: Lower replacement frequency saves cost and labor

What Are the Key Features That Make Aulone Guide Ropes Reliable?

Reliability depends on construction, material, and proper design. Aulone ropes cover all aspects.

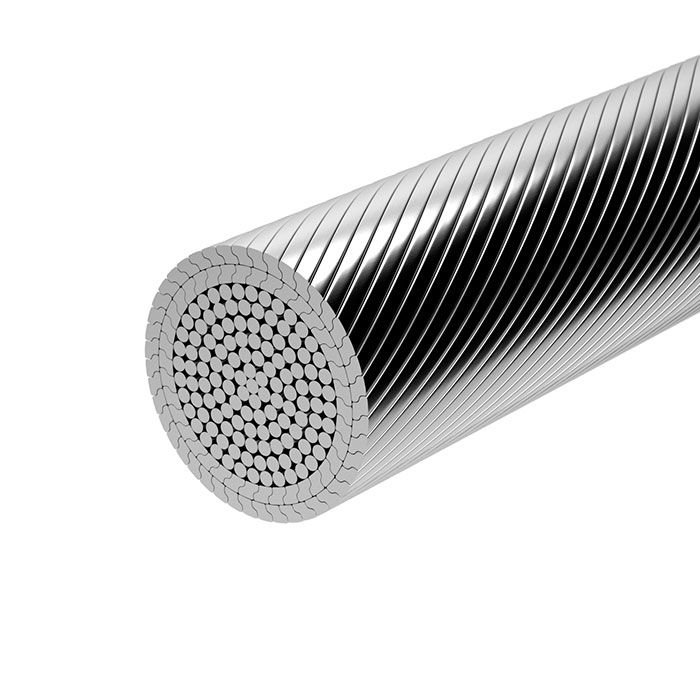

With compacted wires, IWRC cores, multiple steel grades, and galvanization options, Aulone guide ropes meet EN12385-4 standards and client-specific requirements.

Features Breakdown

| Feature | Benefit |

|---|---|

| Compaction | Reduces stretch, increases durability |

| Core (IWRC) | Supports load and minimizes internal wear |

| Steel Grades | Provides high tensile strength (1770–1960 N/mm²) |

| Lay Type | Langs lay for low rotation, Regular lay for general use |

| Lay Direction | RH or LH to suit installation |

| Finish | Bright or Galvanized for corrosion protection |

How Aulone Guide Ropes Handle Abrasion and Wear

Full Lock ropes resist abrasion through compacted wires and IWRC cores. Half Lock ropes combine compaction with lubrication to reduce friction.

| Rope Type | Wear Resistance | Typical Lifespan |

|---|---|---|

| Full Lock | Excellent | 5–8 years |

| Half Lock | High | 4–6 years |

Installation and Maintenance Insights

Proper installation is as important as rope quality:

- Align sheaves carefully

- Apply recommended lubrication for Half Lock ropes

- Avoid twisting or overloading during installation

- Monitor tension and alignment regularly

Real-World Examples

- Southeast Asia Mining Shaft: Full Lock ropes improved conveyance alignment at 20m/sec, reduced downtime by 25%, extended rope lifespan by 3 years.

- Australian Iron Ore Shaft: Half Lock ropes minimized rotation and stretch, reducing maintenance costs by 18%.

- Indonesian Coal Shaft: Aulone guide ropes prevented conveyance drift, improving safety and operational efficiency.

Conclusion

Aulone guide ropes deliver high strength, low rotation, excellent wear resistance, and long service life, ensuring safe and efficient underground mining conveyances. Proper selection and maintenance save costs, reduce downtime, and improve productivity.