Underground mining is risky. Weak ropes cause accidents. Strong ropes protect workers and improve efficiency.

Underground mining ropes must be durable, high-tensile, and compliant with standards to ensure safety and smooth operations in harsh mining environments.

Transition paragraph: I remember visiting a mine where old ropes snapped. The work stopped, and everyone feared injury. That moment convinced me that rope quality is critical.

How Do Underground Mining Ropes Differ from Regular Ropes?

Mining ropes face extreme stress. Not every rope can survive deep underground conditions.

Underground mining ropes are built with high-strength steel, specialized cores, and protective coatings to handle heavy loads, abrasion, and moisture in confined spaces.

Key Design Features

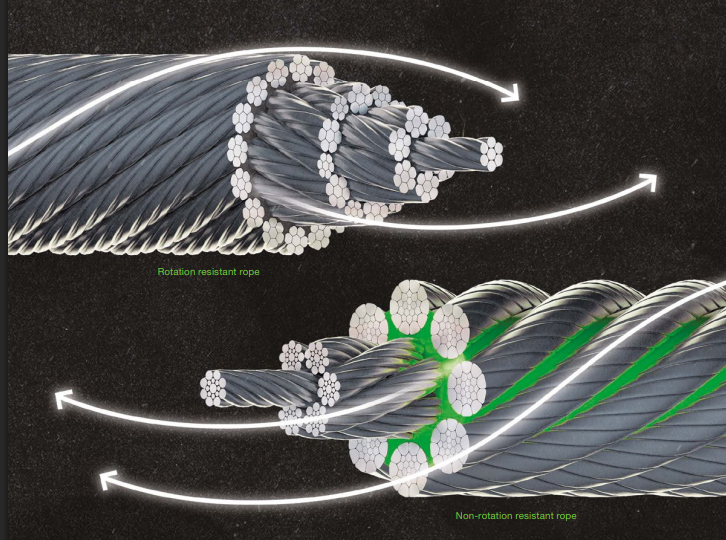

- Core types: Steel wire core vs. fiber core. Steel cores provide extra strength. Fiber cores offer flexibility.

- Strand construction: 6×36, 8×26, and 35WXK7 are popular choices for durability and low stretch.

- Protective coatings: Galvanized or plastic-impregnated ropes resist corrosion in wet tunnels.

| Feature | Purpose | Benefit |

|---|---|---|

| Steel Core | Strength | Handles heavy hoists |

| Fiber Core | Flexibility | Easier to coil and install |

| Galvanization | Corrosion resistance | Longer lifespan |

| Plastic Impregnation | Moisture protection | Reduces internal wear |

What Standards Ensure Underground Mining Rope Safety?

Safety is the top concern in mining. Standards guide rope quality.

Ropes for underground mining comply with EN12385-4 or similar certifications, ensuring tensile strength, breaking load, and durability are verified for demanding mining conditions.

Certification and Testing

- EN12385-4: Specifies rope design, testing, and maintenance for mining operations.

- Third-party verification: BV, CE, RMRS, DNV, ABS ensure compliance.

- Breaking load tests: Confirm ropes meet safety limits.

| Test Type | Purpose | Standard |

|---|---|---|

| Tensile Test | Maximum load | EN12385-4 |

| Abrasion Test | Wear resistance | BV |

| Corrosion Test | Longevity | CE |

How Do I Choose the Right Rope for My Mining Project?

Every mining site has unique conditions. Choosing wrong ropes leads to costly downtime.

Select ropes based on load requirements, shaft depth, and environmental factors. Customizable ropes with steel cores and protective coatings often provide the best safety and efficiency balance.

Selection Guide

- Load rating: Always check the maximum hoist weight.

- Environment: Wet, dusty, or chemical exposure affects rope choice.

- Length and diameter: Ensure rope fits shaft depth and winch.

- Customization options: Logos, lengths, and coatings can be tailored.

| Selection Factor | Recommendation | Notes |

|---|---|---|

| Load | Match rope tensile rating | Include safety factor |

| Environment | Galvanized or plastic-impregnated | Reduces wear |

| Diameter | Based on winch & shaft | Prevents slippage |

| Length | Slightly longer than shaft | Allows flexibility |

How Can Proper Maintenance Extend Rope Life?

Even the strongest rope fails without care. Maintenance saves money and prevents accidents.

Inspect ropes regularly, lubricate cores, and replace damaged sections promptly. Proper maintenance extends life and keeps mining operations safe.

Maintenance Practices

- Regular inspections: Look for broken strands, wear, and corrosion.

- Lubrication: Reduces friction inside the rope, preventing early failure.

- Rotation schedule: Rotating ropes distributes wear evenly.

- Documentation: Track usage hours and replacements for safety audits.

| Maintenance Task | Frequency | Purpose |

|---|---|---|

| Visual Inspection | Weekly | Detect damage early |

| Lubrication | Monthly | Reduce internal friction |

| Rope Rotation | As needed | Even wear distribution |

| Replacement | At wear limit | Avoid accidents |

Conclusion

Strong, certified, and well-maintained underground mining ropes prevent accidents, improve efficiency, and save costs.