Choosing the right security component often feels overwhelming. You want something strong, reliable, and cost-effective. But which one should you trust more—chain or cable?

Cables generally provide better flexibility, tensile strength, and corrosion resistance than chains, making them ideal for dynamic and sensitive environments. Chains are better in high-impact, static settings where rigidity is beneficial.

Last month, I helped a crane company that faced a dilemma during an urgent repair—should they go with a chain or a wire rope cable? Their equipment operated in a humid coastal area, and what they chose ended up saving them both time and future maintenance costs. Let’s explore how you can make the right decision too.

What Are the Key Differences Between Security Chains and Cables?

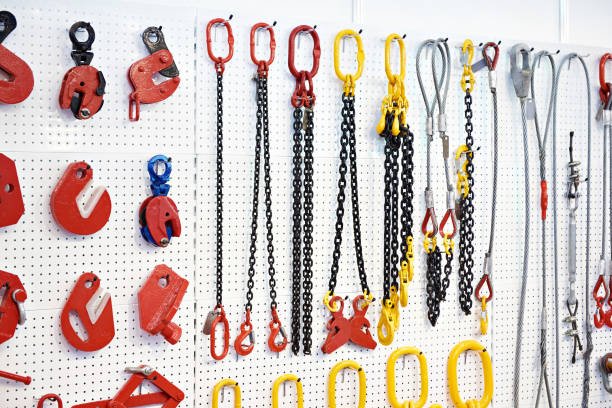

Chains and cables are both designed to secure objects or support heavy loads. They are part of critical systems in construction, cranes, mining, shipping, and more. But the way they perform in different situations varies a lot.

Chains offer rigid strength and durability, while cables deliver higher tensile properties with more flexibility. The right choice depends on your applications, environmental conditions, and movement requirements.

Dive Deeper

Let’s first look at the physical and structural differences.

- Chains are made from individual metal links. Because the links are solid and interconnected, they offer excellent static strength. They resist cutting and are harder to bend. In extreme load situations or where movement is minimal, chains hold up well.

- Cables, or wire ropes, typically consist of several strands of steel wire twisted together. This twisting structure gives wire rope great flexibility. It evenly distributes weight and tension, reducing stress points.

I usually recommend cables for clients who operate in tight spaces or environments where equipment is in constant motion. The cable can bend, move, and adapt to new positions without breaking, which chains simply can’t manage.

Feature Comparison Table

| Feature | Chains | Cables (Wire Rope) |

|---|---|---|

| Construction | Interlinked solid metal loops | Multiple strands twisted together |

| Flexibility | Low | High |

| Weight | Heavier | Lighter |

| Tensile Strength | Moderate to High | High to Very High (up to 1800 MPa) |

| Corrosion Resistance | Moderate (galvanized options) | High (galvanized + plastic impregnated) |

| Load Distribution | Focused on one point | Spread across multiple wires and strands |

| Application Movement | Better for static use | Ideal for dynamic or bending applications |

For offshore platforms or elevators, cables win every time. But for factory floor lifting systems that move slowly and carry heavy loads, chains may be more appropriate.

How Do Certifications Impact Safety Standards for Chains and Cables?

Getting the strongest material is only half the job. Certifications are the real proof of quality. Industrial buyers often overlook this, but it’s the first thing I look for when I receive an inquiry.

Certifications like EN12385-4 or CE ensure that cables and chains meet industry safety requirements. Without them, you’re risking product failure, safety issues, and insurance problems.

In my factory, we follow strict procedures in all four production lines. The wire rope we produce undergoes multiple break-load tests. We can provide CE, BV, ABS, and even Russian RMRS certifications depending on the client’s need.

Dive Deeper

Let’s break down what these certifications actually mean:

Common Certifications and Their Role

| Certification | Description |

|---|---|

| EN12385-4 | European standard for wire rope safety and strength |

| CE Mark | Shows conformity with health, safety, and environmental protection laws |

| DNV/ABS | Required for marine and offshore use, especially in oil platforms |

| BV (Bureau Veritas) | Verifies quality management and product safety |

| RMRS | Required for products used in Russian marine projects |

If you’re in marine or oil industries, lacking DNV or ABS can completely disqualify your shipment. Imagine investing thousands on wire rope, only to find it rejected at customs. That’s why working with certified suppliers is critical.

What Factors Should Influence Your Purchase Decision?

Many buyers I’ve worked with initially focus on price. It’s a valid concern, but price should never be the top factor. There are many other things to consider first.

Your final choice should be based on application environment, load requirements, usage frequency, and corrosion resistance—not just price. Going cheaper sometimes leads to higher long-term maintenance costs.

If a client works in a mining area with acidic exposure, I always suggest stainless steel wire rope or plastic-impregnated wire. It may cost 15% more upfront, but it easily lasts 2–3 times longer and maintains safety.

Comparison Chart: When to Choose What

| Application Environment | Suggested Material | Why |

|---|---|---|

| Coastal Area or Marine | Plastic-impregnated cable | High corrosion resistance |

| Indoor Factory | Galvanized chain or cable | Cost-effective with basic protection |

| High Temperature Facility | Steel cable with heat resistance | Withstands thermal expansion |

| Construction Site | Wire rope (EN12385-4 standard) | Flexibility + strength |

| Mining Location | Stainless steel cable | Durable under impact + corrosion |

When I worked with a Vietnamese client in the oil drilling industry, we faced rusting issues with their local products. They switched to our galvanized cable with plastic coating. After 9 months of use, they reported zero corrosion—a simple yet powerful change.

How Can You Ensure Quality Control When Sourcing?

In today’s global sourcing landscape, not all suppliers meet the same quality level. Choosing the wrong partner could not only delay your deliveries but also damage your brand.

To ensure quality, always request material certificates, test reports, and understand the supplier’s production process. On-site video audits and third-party inspections can provide additional peace of mind.

Clients often ask me: “Is 316 stainless steel really better than 304?” I walk them through the specs and also show them visual samples from our production line.

Quality Assurance Checklist

| Item | What to Look For |

|---|---|

| Raw Material Origin | Imported high-quality steel or reputable domestic supply |

| Factory Equipment | In-house labs, break-load testing equipment |

| Certificates | EN12385-4, CE, ABS, RMRS |

| Inspection Standards | Internal + external third-party testing (SGS, BV, etc.) |

| Sample Policy | Sample rope sections with testing documents |

Also, ask about production capacity. A fully equipped factory, like ours with four dedicated production lines, means you get faster turnaround on both standard and customized orders.

Conclusion

Cables offer better performance in strength, flexibility, and longevity. Chains are tough but less adaptable. Make your decision based on application and certified quality.