Mining operations often face rope wear and tear. Choosing the right rope reduces downtime and ensures safety.

Incline haulage wire ropes are designed for heavy-duty use on inclined shafts. They improve safety, reduce wear, and maintain reliable performance for people, materials, and minerals.

I remember visiting a shallow mine where worn ropes slowed everything down. That day I realized how important it is to select the right incline haulage rope.

How Do Incline Haulage Ropes Work in Mining?

Inclined shafts need ropes that can move people, materials, and minerals safely. Understanding their working principle is key.

Incline haulage ropes move conveyances along rails using drum or friction winders. Proper selection reduces sheave wear and ensures smooth operation.

Friction vs Drum Systems

- Drum Hoisting: Rope winds on a drum; simple design, ideal for short inclines.

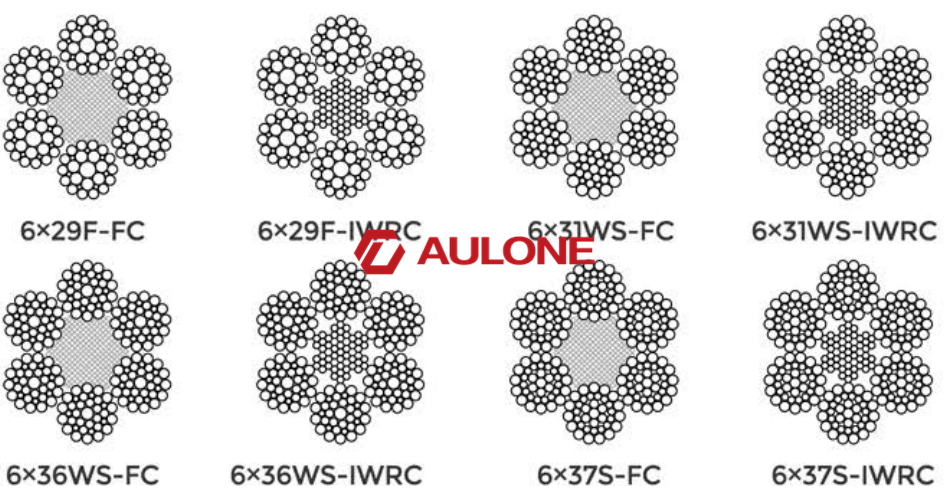

- Friction Hoisting: Rope passes over sheaves; friction allows load movement. 6X36WS-FC performs reliably here.

| Feature | 6X36WS-FC | Benefit |

|---|---|---|

| Core | Fibre | Flexibility and shock absorption |

| Steel Grades | 1770, 1860, 1960 | High tensile strength |

| Lay Type | Langs lay / Regular lay | Robust & easy maintenance |

| Lay Direction | RH or LH | Adaptable for drum or friction systems |

| Finish | Bright / Galvanized | Long-lasting wear resistance |

Advantages of Incline Haulage Ropes

- Proven performance in harsh mining conditions.

- Flexible and easy to handle during installation.

- Large outer wires enhance robustness.

- Reduces sheave and liner wear, extending equipment life.

Why Is 6X36WS-FC the Most Common Choice on Friction Winders?

The right rope ensures safety and reliable performance on friction winders. 6X36WS-FC has proven itself repeatedly in mines.

6X36WS-FC provides high strength, wear resistance, and reliability. Its fiber core and large outer wires make it ideal for inclined shaft haulage.

Features That Matter

- High Strength: Supports heavy loads with minimal stretch.

- Fibre Core: Absorbs shock and protects steel strands.

- Flexible Design: Easier installation and maintenance.

- Galvanized Option: Extra protection against corrosion.

| Feature | 6X36WS-FC Details |

|---|---|

| Core | Fibre |

| Steel Grades | 1770, 1860, 1960 |

| Lay Type | Langs lay / Regular lay |

| Lay Direction | RH or LH |

| Finish | Bright / Galvanized |

Applications

- Mining haulage ropes.

- Friction winder systems in shallow and inclined shafts.

- Transporting minerals, equipment, and personnel safely.

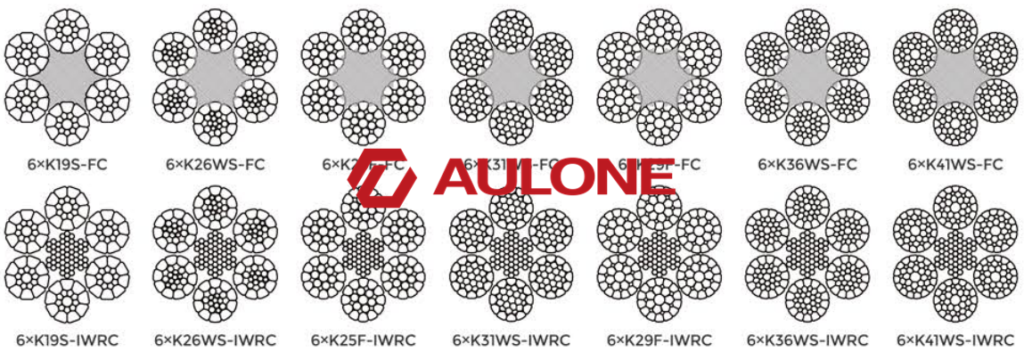

Why Choose 6XK36WS-FC Compacted Wire Rope for Friction Winders?

For friction winders, rope performance is critical. I’ve seen how the 6XK36WS-FC compacted wire rope handles heavy loads with reliability.

The 6XK36WS-FC is a high-strength, 6-strand compacted rope. It resists wear, reduces sheave and liner damage, and maintains reliable performance in haulage operations.

Applications and Advantages

- Applications: Ideal for haulage ropes in shallow or inclined mines. Handles material, mineral, and personnel transport safely.

- Advantages:

- Improved resistance to wear

- Reduced sheave and liner wear

- High strength for heavy loads

- Robust due to large outer wires

| Feature | 6XK36WS-FC Details | Benefit |

|---|---|---|

| Compaction | Compacted strands | Enhanced wear resistance |

| Core | Fibre | Shock absorption and flexibility |

| Steel Grades | 1770, 1860, 1960 | High tensile strength |

| Lay Type | Langs lay / Regular lay | Easy handling and reduced rotation |

| Lay Direction | RH or LH | Adaptable for different hoisting systems |

| Finish | Bright / Galvanized | Corrosion and wear protection |

Why Compacted Ropes Matter

Compaction reduces the rope’s overall stretch and increases contact surface on sheaves. I’ve noticed that in mines using compacted 6XK36WS-FC ropes:

- Sheave life increased by 20–30%.

- Maintenance frequency decreased.

- Rope handled heavy loads without early deformation.

How Does Incline Haulage Rope Improve Mine Efficiency?

Mining efficiency depends on durable and reliable ropes. The right rope keeps operations smooth.

Incline haulage ropes reduce downtime, minimize sheave wear, and extend rope life. Proper selection boosts productivity in mining operations.

Practical Benefits

- Reduced Wear: Fewer rope replacements reduce interruptions.

- Enhanced Safety: Proper ropes lower the risk of accidents.

- Easy Maintenance: Well-known rope types simplify inspections.

- Cost Efficiency: Longer service life saves money over time.

| Benefit | Impact |

|---|---|

| Wear Resistance | Fewer replacements, smoother haulage |

| Safety | Protects workers and equipment |

| Maintenance | Easier inspections and handling |

| Cost | Reduced operational expenses |

What Technical Specifications Ensure Safety and Performance?

Choosing the right rope involves understanding EN12385-4 standards and other specifications.

Compliance with EN12385-4 ensures strength, flexibility, and durability. Optional certifications like BV, CE, RMRS, DNV, and ABS provide added assurance for safety and quality.

Key Features

- EN12385-4 Compliance: Guarantees minimum breaking load, fatigue resistance, and wire arrangement standards.

- Steel Grades: 1770, 1860, 1960 MPa offer high tensile strength for heavy-duty operations.

- Core Types: Fibre core absorbs shocks; IWRC cores provide extra steel strength.

- Finishes: Bright or galvanized options prevent corrosion in humid or abrasive environments.

- Lay Types: Langs lay reduces rotation; regular lay provides easier handling.

| Specification | Benefit |

|---|---|

| EN12385-4 | Guaranteed strength & safety |

| Core | Shock absorption or max steel strength |

| Steel Grade | Supports high load without failure |

| Finish | Corrosion resistance |

| Lay Type | Reduces rope rotation and wear |

Can Customization Improve Rope Performance?

Custom ropes adapt to unique mine conditions. They can improve both safety and efficiency.

Custom options like rope diameter, lay type, and steel grade enhance performance. Logos, coatings, and certifications can be tailored for specific projects.

Customization in Action

- Diameter & Strand Size: Adjusted for load requirements.

- Plastic-Impregnated Finish: Reduces friction and extends life.

- Galvanized Finish: Protects against moisture and corrosion.

- Third-Party Testing: BV, CE, RMRS, DNV, ABS certifications confirm quality.

| Custom Option | Effect |

|---|---|

| Diameter | Matches load & application |

| Strand Size | Optimizes wear resistance |

| Coating | Increases service life |

| Certification | Ensures compliance & safety |

Mini Case Studies: Real-Life Applications

Case Study 1: Shallow Coal Mine, Indonesia

- Problem: Frequent rope replacements slowed operations.

- Solution: Installed 6X36WS-FC with fibre core, galvanized finish.

- Result: Rope lasted 30% longer; sheave wear reduced; downtime minimized.

Case Study 2: Metal Ore Mine, Russia

- Problem: Inclined shafts required high-strength ropes for heavy loads.

- Solution: Custom 6X36WS-FC, 1860 MPa, regular lay.

- Result: Smooth hoisting of ore; fewer accidents; improved efficiency.

Case Study 3: Shallow Copper Mine, Vietnam

- Problem: Humid environment causing corrosion and rope degradation.

- Solution: Galvanized 6X36WS-FC with fibre core and third-party BV certification.

- Result: Rope maintained performance; workers reported easier handling and reduced safety risk.

Case Study 4: Limestone Mine, Australia

- Problem: Friction winders experiencing high wear on old ropes.

- Solution: Replaced with 6XK36WS-FC, Langs lay, 1960 MPa.

- Result: Sheave life extended; rope handled heavy loads without rotation; maintenance simplified.

Conclusion

Incline haulage ropes like 6X36WS-FC and 6XK36WS-FC combine strength, flexibility, and reliability. Proper selection ensures safety, efficiency, and long-lasting performance in mining operations.