Heavy lifting fails when ropes break unexpectedly. I know how frustrating delays can be. Choosing the right wire rope can prevent accidents and downtime.

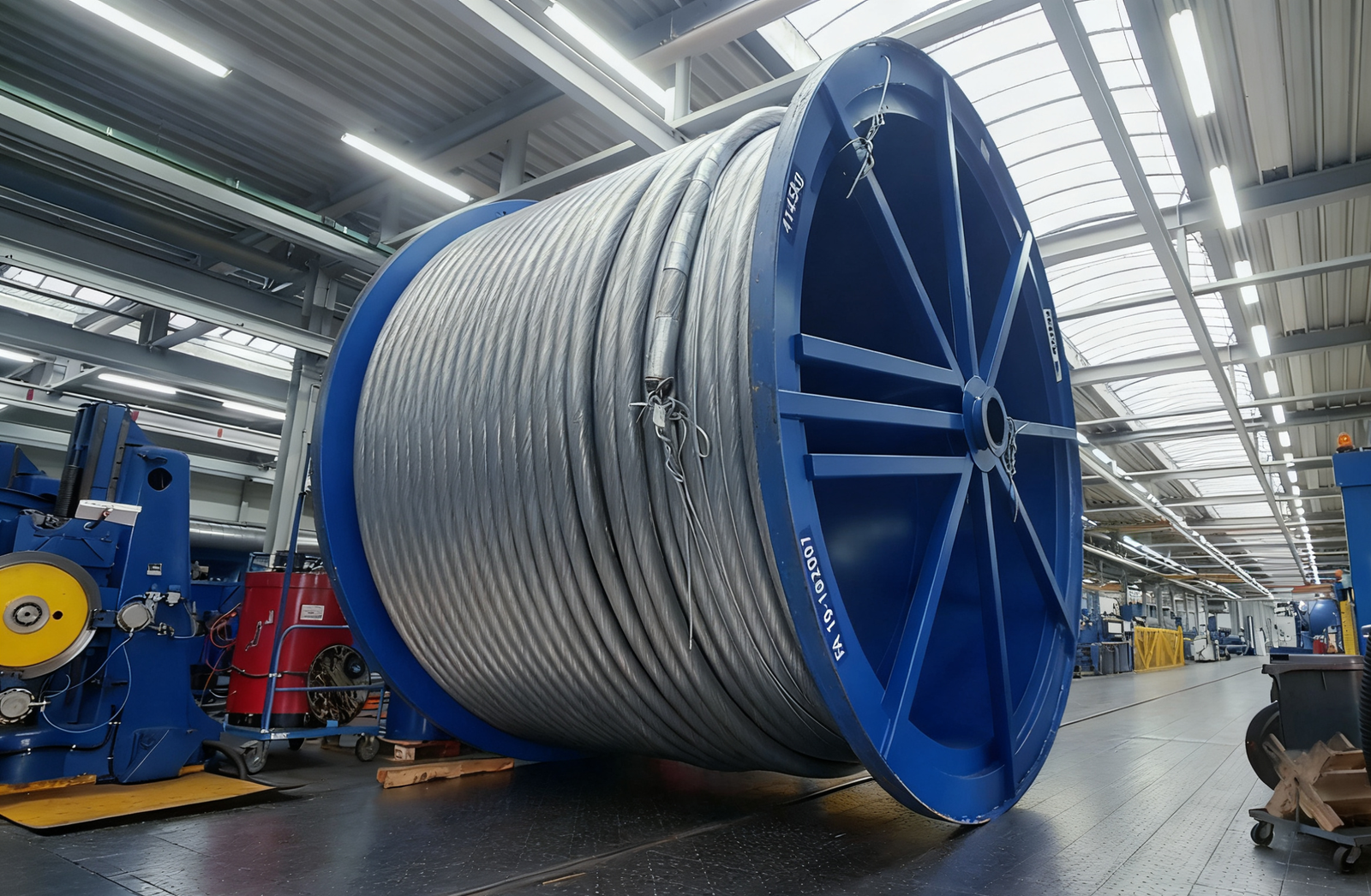

Drum winder and mining wire ropes provide high strength, excellent spooling, and durability. They handle extreme pressures, resist rotation, and maintain diameter stability under load.

I still remember our first large mining order. The right rope choice saved weeks of downtime. Let me show why certain constructions outperform others in harsh environments

What are the key features of the 35WXK7-EPIWRC rope?

Why does the 35WXK7-EPIWRC stand out in multi-layer drum operations?

This rope combines high strength with flexibility. PI core intrusion ensures excellent diameter stability. It resists rotation and performs well under heavy thread pressure

Polymer enhancements and Plastic Impregnation

Plastic injection improves core life and reduces bend fatigue. This technology extends the rope’s service life in high-stress hoist operations.

| Feature | Benefit |

|---|---|

| High Strength | Handles extreme loads safely |

| Excellent Spooling | Smooth operation on multi-layer drums |

| PI Intrusion | Maintains diameter stability |

| Best D/d ratio | Reduces wear on sheaves and drums |

Applications of 35WXK7-EPIWRC

| Application | Details |

|---|---|

| Tower Mounted Friction Hoist with Deflectors | Ensures smooth lifting in tall structures |

| Ground Mounted Friction Hoist | Handles heavy loads efficiently |

| Blair Hoist | Reduces downtime with flexible operation |

| Parallel Drum Hoist | Maintains rope stability over long distances |

| Stage Sinking Ropes | Ideal for controlled deep mining |

Advantages of 35WXK7-EPIWRC

| Advantage | Benefit |

|---|---|

| Flexibility | Easier handling and installation |

| Resistance to Rotation | Prevents twisting and accidents |

| Smart D/d ratio | Reduces fatigue on drums and sheaves |

| Diameter Stability | Maintains performance under load |

Technical Features

- Compaction: Yes

- Core: IWRC with PI

- Steel Grades: 1770, 1860, 1960

- Lay Type: Langs or Regular Lay

- Lay Direction: RH or LH

Maintenance Tips for 35WXK7-EPIWRC

- Regularly inspect the rope for broken wires and wear

- Lubricate with compatible rope grease to reduce friction

- Check spooling on multi-layer drums to prevent crossovers

- Monitor D/d ratio to avoid excessive bending stress

Why is the 6XK36WS-FC rope preferred for friction winders?

How does the 6XK36WS-FC rope improve mining haulage performance?

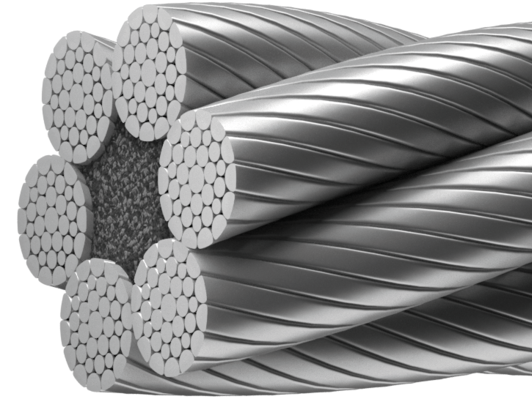

This 6-strand rope delivers consistent strength, wear resistance, and flexibility. Big outer wires reduce sheave wear, while advanced core technology ensures long life.

Proven Friction Winder Performance

The 6XK36WS-FC is widely used underground due to reliable operation and robust construction. Its Fiber core ensures advanced diameter stability, extending rope lifetime.

| Feature | Benefit |

|---|---|

| High Strength | Reliable under heavy haulage loads |

| Wear Resistance | Protects sheaves and liners |

| Flexible | Easier handling and installation |

| Bristar® Core | Maintains diameter and performance |

Applications of 6XK36WS-FC

| Application | Details |

|---|---|

| Haulage ropes | Efficient for moving ore and materials |

| Underground friction winders | Stable operation in tunnels |

| Mining hoists | Handles continuous heavy lifting |

Advantages of 6XK36WS-FC

| Advantage | Benefit |

|---|---|

| Proven performance | Well known for maintenance and reliability |

| Advanced diameter stability | Long rope life, reduces replacement cost |

| Flexible | Easy to install and maneuver |

| Robust construction | Big outer wires resist wear and abrasion |

Technical Features

- Rope Type: 6-strand, FC or IWRC options

- Core: fiber core for different wear patterns

- Lay Type: Regular or Langs lay

- Lay Direction: RH or LH

- Steel Grade: 1770, 1860, 1960

Maintenance Tips for 6XK36WS-FC

- Check for wire breaks at bends and sheaves

- Rotate rope periodically to balance wear

- Keep sheaves clean to reduce abrasion

- Inspect diameter regularly for core compression

How can proper rope selection impact mining operations?

Why does choosing the correct wire rope matter so much in mining?

Proper rope selection reduces downtime, improves safety, and extends equipment life. Right construction resists wear, rotation, and high loads in harsh underground conditions

Safety and Efficiency

Selecting the wrong rope can cause accidents and costly delays. I’ve seen sites replace ropes too often. Using ropes like 35WXK7-EPIWRC or 6XK36WS-FC saves time, money, and stress.

| Risk | Solution |

|---|---|

| Premature wear | Use plastic impregnated or PI core ropes |

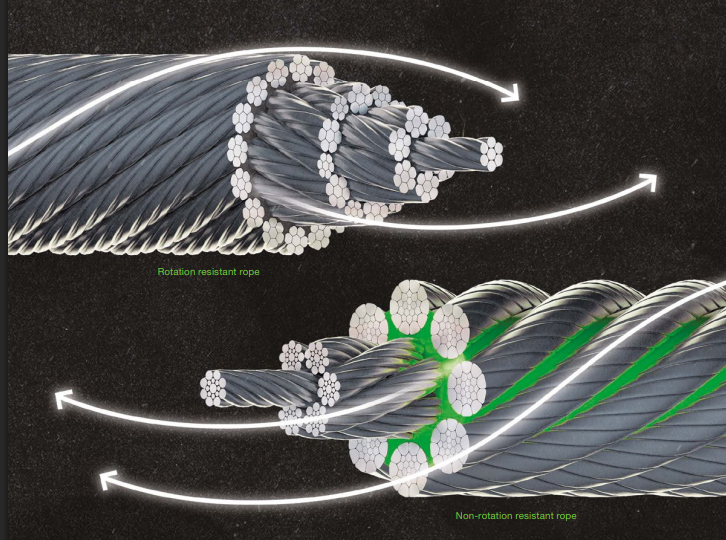

| Rope rotation | Choose non-rotating constructions |

| Downtime | Select ropes with proven performance |

| Sheave or drum damage | Use ropes with proper D/d ratio and flexibility |

Real-world Example

When our team supplied a 35WXK7-EPIWRC for a deep shaft hoist, the client reduced rope replacements from 3 per year to 1. They saved thousands in downtime and maintenance costs.

How do 35WXK7-EPIWRC and 6XK36WS-FC compare for mining applications?

Which rope should you choose: 35WXK7-EPIWRC or 6XK36WS-FC?

Both ropes offer high strength and durability. 35WXK7-EPIWRC excels in multi-layer drum spooling. 6XK36WS-FC is ideal for friction winders with robust haulage performance.

Side-by-side Comparison

| Feature | 35WXK7-EPIWRC | 6XK36WS-FC |

|---|---|---|

| Strength | Very High | High |

| Flexibility | Excellent | Good |

| Spooling on multi-layer drums | Excellent | Moderate |

| Rotation resistance | Very High | High |

| Core | IWRC with PI | Bristar® |

| Wear resistance | High | Very High on sheaves |

| Best use | Tower and parallel drum hoists | Friction winders and haulage |

Choosing the Right Rope

- Use 35WXK7-EPIWRC when spooling efficiency and flexibility are critical

- Use 6XK36WS-FC for long haulage runs and underground mining with heavy loads

- Consider maintenance capabilities and replacement schedules

What are practical tips for installing and inspecting mining ropes?

How can proper installation and inspection extend rope life?

Correct installation reduces bending fatigue and sheave wear. Regular inspections prevent failures and improve operational safety.

Installation Tips

| Step | Advice |

|---|---|

| Pre-stretch rope | Reduces elongation under load |

| Spool carefully | Avoid crossovers on multi-layer drums |

| Sheave alignment | Prevents uneven wear |

| Proper tension | Maintains optimal D/d ratio |

Inspection Tips

| Check | Frequency | Notes |

|---|---|---|

| Broken wires | Weekly | Focus on bends and load points |

| Core condition | Monthly | Look for core compression or PI intrusion issues |

| Diameter measurement | Monthly | Compare to original rope diameter |

| Lubrication | As needed | Use compatible grease to reduce wear |

Buyer’s Quick Reference Table: Drum Winder & Mining Ropes

| Rope Type | Best Use | Strength | Flexibility | Rotation Resistance | Core Type | Spooling Performance | Wear Resistance | Maintenance Tips | Applications |

|---|---|---|---|---|---|---|---|---|---|

| 35WXK7-EPIWRC | Tower & Parallel Drum Hoists | Very High | Excellent | Very High | IWRC with PI | Excellent on multi-layer drums | High | Inspect weekly, lubricate, monitor D/d ratio, check diameter | Tower Mounted Friction Hoist, Ground Mounted Hoist, Blair Hoist, Parallel Drum Hoist, Stage Sinking Ropes |

| 6XK36WS-FC | Friction Winders & Haulage | High | Good | High | FC | Moderate | Very High on sheaves | Inspect weekly for broken wires, monthly for core and diameter, rotate periodically, keep sheaves clean | Haulage Ropes, Underground Friction Winders, Mining Hoists |

Key Practical Tips for Buyers

- Spooling Matters – Use 35WXK7-EPIWRC for multi-layer drum operations to reduce fatigue and ensure smooth spooling.

- Core Technology – PI intrusion in 35WXK7-EPIWRC and Bristar® core in 6XK36WS-FC enhance diameter stability and lifetime.

- Maintenance Schedule – Inspect broken wires weekly, measure diameter monthly, and lubricate ropes as needed.

- Rotation Resistance – Non-rotating constructions reduce rope twisting and potential accidents.

- Correct D/d Ratio – Ensure sheave and drum diameters match rope D/d ratio to reduce wear and extend rope life.

Conclusion

High-quality drum winder and mining ropes save time, improve safety, and increase operational efficiency. Correct choice, installation, and inspection maximize rope lifetime.