Does your load spin dangerously during a lift? This uncontrolled rotation is not just inefficient; it’s a major safety hazard. The solution is using a specialized rope designed to prevent this exact problem.

A rotation resistant wire rope is a special type of steel cable. Its inner and outer strands are wrapped in opposite directions. This design counteracts the rope’s natural tendency to twist or spin when lifting a load.

I’ve been in this industry for a long time. I remember a client telling me about a close call on a high-rise construction site. A standard rope started to spin, and a heavy steel beam nearly hit the side of the building. This is why we need to talk about this.

How Do These Ropes Actually Stop The Load From Spinning?

You might wonder what’s happening inside the rope. It seems simple from the outside, but the internal design is very clever. It’s all about balance.

Rotation resistant ropes work by using opposing forces. The inner core and its strands are twisted in one direction. The outer layers of strands are twisted in the opposite direction. When a load is applied, these forces cancel each other out.

Let’s dive a bit deeper into this engineering.

The Core Principle: A Tug-of-War Inside The Rope

Think of it like a game of tug-of-war. A normal wire rope has all its strands pulling in the same rotational direction. When you put a heavy load on it, that rotational force has to go somewhere, so the rope spins.

A rotation resistant rope creates a tug-of-war within itself.

- Inner Layers: These strands might be twisted to the right (Right Hand Lay).

- Outer Layers: These strands are then twisted to the left (Left Hand Lay).

Under load, the inner layers want to untwist to the left. At the same time, the outer layers want to untwist to the right. Because these forces are working against each other, the rope stays stable and the load does not spin. This simple concept is what makes your lifting operations so much safer.

A Layer-by-Layer Look

The number of layers and the complexity of the design determine how resistant the rope is. The more layers with opposing lays, the better the resistance.

Here is a simple breakdown of a common construction, like a 35×7 rope:

| Rope Component | Direction of Twist (Lay) | Purpose |

|---|---|---|

| Inner Core (e.g., 7 strands) | Right Hand Lay | Creates the initial rotational force. |

| Intermediate Layer (e.g., 14 strands) | Left Hand Lay | Counteracts the core’s force. |

| Outer Layer (e.g., 14 strands) | Right Hand Lay | Counteracts the intermediate layer’s force. |

This multi-layer system creates a very stable balance. It ensures that even with very heavy loads and single-line lifting, the rope remains neutral.

Why This Matters in Practice

In the real world, this internal design has huge benefits. On a busy construction site, a crane operator needs to place a load precisely. If the load is spinning, they waste time waiting for it to stop. Worse, it could swing out of control. With a rotation resistant rope, the operator has full control. They can lift, move, and place the load efficiently and, most importantly, safely.

What Are The Main Types Of Rotation Resistant Ropes?

Knowing that you need a rotation resistant rope is the first step. But there isn’t just one type. They are classified based on how well they resist rotation.

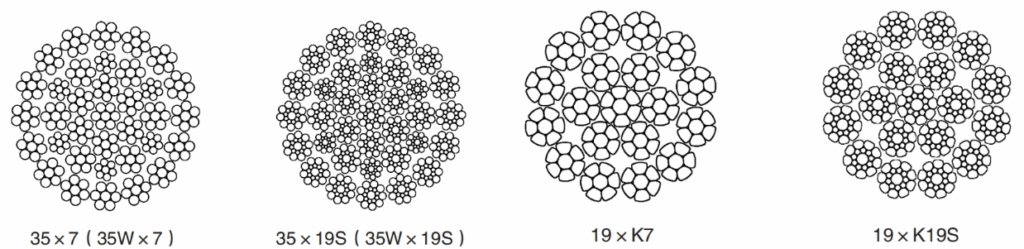

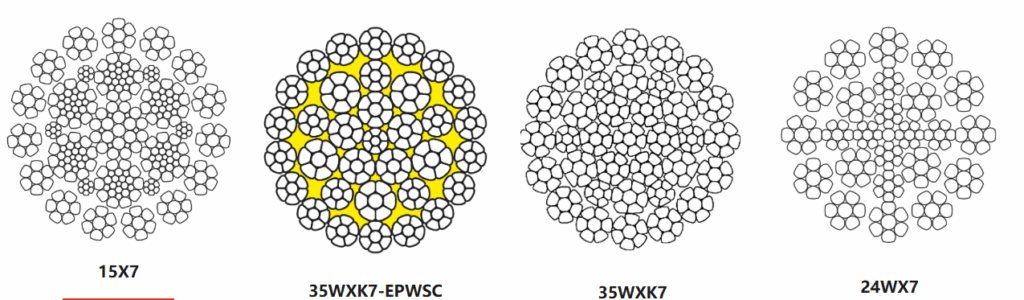

The main types are categorized by their construction, like 19×7 or 35×7. These numbers describe the strands and wires. Generally, they fall into three groups: spin-resistant, rotation-resistant, and non-rotating, each offering a higher level of performance.

Let’s look at what these categories mean for your project.

Spin-Resistant Ropes (Good)

These are the entry-level ropes for controlling rotation. A common example is the 19×7 construction.

- Structure: It has a core of 7 strands and an outer layer of 12 strands, all wrapped around a central wire. The inner and outer layers are laid in opposite directions.

- Performance: They offer good resistance to spin but are not truly “non-rotating.” They work best in situations where the load is guided or when using a multi-part reeving system (where multiple lines are used). They are not recommended for single-line lifts where the rope can spin freely.

Rotation-Resistant Ropes (Better)

This is the most common category and offers a significant upgrade in performance. Ropes like 35×7 fall into this group.

- Structure: These have more layers. A 35×7 rope has several layers of strands wrapped in opposing directions, which creates a more stable balance of forces. At our factory, we can even add a plastic impregnation layer to these ropes. This locks the strands in place, further increasing stability and protecting against corrosion.

- Performance: They are excellent for many crane applications, including some single-line lifts. They offer a great balance of performance, flexibility, and cost.

Non-Rotating Ropes (Best)

These are the highest-performance ropes available. They are designed for the most demanding jobs, especially high-altitude, single-line lifts where any rotation is unacceptable.

- Structure: They have a very complex design with multiple layers of strands, all engineered to perfectly cancel out any rotational force.

- Performance: They provide the maximum resistance to spinning. They are the go-to choice for tower cranes, mobile cranes doing critical single-line lifts, and offshore applications.

Here’s a quick comparison to help you choose:

| Category | Common Construction | Resistance Level | Best For |

|---|---|---|---|

| Spin-Resistant | 19×7 | Good | Guided loads, multi-part reeving systems. |

| Rotation-Resistant | 35×7 | Better | General crane use, some single-part lines. |

| Non-Rotating | Complex (e.g., 34LR) | Best | High lifts, unguided single-part lines, critical lifts. |

Why Is Using The Right Rope So Critical For Your Operation?

Choosing the cheapest rope might save money upfront. But using the wrong rope, especially in lifting, can lead to much bigger costs down the line. It’s about more than just a feature.

Using the correct rotation resistant rope is critical for three main reasons: it dramatically improves safety, it increases operational efficiency by giving better load control, and it ultimately extends the service life of the rope itself.

Let’s explore why these points are so important to purchasing managers and site supervisors.

Enhancing On-Site Safety

This is the number one reason. An uncontrolled, spinning load is a deadly hazard. It can strike personnel, collide with structures, or cause the rigging to fail. I have heard too many stories about accidents that could have been prevented. Using a rope that keeps the load stable removes this risk. It creates a safer working environment for everyone on the ground and gives the crane operator peace of mind.

Improving Load Control and Placement

Time is money on any project. When a crane operator has to fight a spinning load, it takes longer to position it. They have to lift, wait for the spin to die down, and then try to lower it into place. This is incredibly inefficient.

A stable load, held steady by a rotation resistant rope, can be placed with precision on the first try. This speeds up the entire workflow, whether it’s setting steel beams, pouring concrete, or loading cargo onto a ship.

Extending the Service Life of Your Rope

Rotation doesn’t just happen to the load; it creates intense stress inside the wire rope. This internal torque can cause the strands to rub against each other, leading to premature wear and internal wire breaks. These are often invisible from the outside.

By using a rope designed to resist this torque, you are also protecting the rope itself. The internal components remain in their proper positions, reducing friction and wear. A rope that lasts longer means lower replacement costs and less downtime for your equipment. Our ropes are built to a high tensile strength, and using them correctly ensures you get the full value from that strength.

How Do I Choose The Right Rotation Resistant Rope?

With different types and benefits, how do you make the right choice? It can feel complicated, but a systematic approach makes it simple.

To choose the right rope, you must first check your crane’s manual for OEM specifications. Then, consider your application: lifting height, load weight, and whether it’s a single or multi-part line. Finally, ensure the rope has the right certifications.

Let’s break this down into a simple, step-by-step process.

Step 1: Always Start with the Crane Manufacturer’s Manual

This is the most important rule. Your crane was designed and tested with a specific type of wire rope in mind. The Original Equipment Manufacturer (OEM) manual will specify the required diameter, minimum breaking load, and often the rope construction (e.g., 35×7). Never use a rope that does not meet these minimum requirements. Ignoring the manual can void your warranty and compromise safety.

Step 2: Analyze Your Lifting Application

Next, think about the job itself. Ask yourself these questions:

| Factor | Question to Ask Yourself | Why It Matters |

|---|---|---|

| Lifting Height | Will I be doing high lifts (e.g., over 30 meters)? | The higher the lift, the more a rope will try to spin. High lifts demand better rotation resistance. |

| Line Configuration | Is it a single-line lift or a multi-part reeving system? | Single-line lifts are very prone to spinning and require a high-quality rotation-resistant or non-rotating rope. |

| Load | What is the weight of my typical load? | You need a rope with a Minimum Breaking Load (MBL) that provides a safe working margin, usually a 5:1 safety factor. |

| Environment | Will the rope be used in a marine or corrosive environment? | If so, you should choose a galvanized or even a plastic-impregnated rope for extra protection and longer life. |

Step 3: Insist on Quality and Certification

A rope is only as good as the quality control behind it. I’ve seen customers struggle with cheap ropes that fail prematurely or don’t perform as advertised. Always buy from a reputable manufacturer.

Look for ropes that comply with international standards like EN12385-4. Also, ask for third-party certifications if your project requires it. At Aulone, we can provide certificates from bodies like BV, ABS, DNV, or RMRS. This is your proof that the rope you are buying has been tested and meets the highest standards for strength and performance.

What Are Some Key Handling And Maintenance Tips?

You can buy the best rope in the world, but if you don’t handle and maintain it correctly, you won’t get the performance or life you paid for. Proper care starts from the day you receive it.

The most important tips are: handle the rope carefully during installation to avoid inducing twist, conduct regular and thorough inspections for any damage, and ensure it is properly lubricated to protect it from corrosion and internal friction.

Here are the essential practices I always recommend to my clients.

Proper Installation is Critical

The life of a rotation resistant rope can be ruined before it even lifts its first load. Never, ever unspool a rope by dropping the coil on its side and pulling from it. This will put twists into the rope that will permanently damage its rotation resistant properties.

The correct way is to mount the reel on a stand and pull the rope straight off. This ensures no unintended twisting is introduced. Also, when attaching end-fittings, make sure the rope is not allowed to untwist.

The Importance of Regular Inspections

A wire rope is a consumable item. It wears out over time. Your job is to spot the signs of wear before it becomes a safety risk. A regular inspection schedule is not optional; it’s essential.

Here’s a simple checklist of what to look for:

| Issue to Look For | What It Looks Like | Action to Take |

|---|---|---|

| Broken Wires | Snapped individual wires on the rope’s surface. | Follow industry guidelines for the maximum number of broken wires allowed. If exceeded, remove the rope from service. |

| Core Protrusion or “Bird-caging” | The outer strands bulge out, and the core might be visible. | This is a sign of severe internal damage. Remove the rope from service immediately. |

| Corrosion | Red rust on the surface or signs of internal corrosion. | Light surface rust can be cleaned and lubricated. Heavy or internal corrosion weakens the rope significantly. |

| Kinks or High Stranding | Sharp bends or areas where one strand sits high above the others. | These are points of permanent damage and weakness. Remove the rope from service. |

Lubrication and Proper Storage

A wire rope is a machine with many moving parts. Lubrication is vital. It reduces friction between the strands and wires, and it protects against corrosion. Follow the manufacturer’s recommendation for the type and frequency of lubrication.

When you are not using the rope, store it in a dry, clean place away from chemicals or extreme temperatures. Keeping it on the reel and covered will protect it from damage and the elements.

Conclusion

Choosing the right rotation resistant rope improves safety, boosts efficiency, and protects your equipment. It is an investment in a smoother, more secure operation for everyone involved.