You have an old wire rope. It is too long. Can you just cut it and use it again? This sounds like a simple fix. But it is very dangerous.

Cutting a wire rope changes its strength. It can cause many problems. You should never cut a wire rope and then reuse it. This puts lives and projects at risk.

A few years ago, I met a client in Australia. He worked with German brands. He understood good quality. He asked me about rope safety. He wanted to know how different uses affect rope life. This made me think about a common question: what if you just cut a wire rope?

Does Cutting Wire Rope Make it Weaker?

You might think cutting a rope is harmless. But it is not. This action damages the rope. It can lead to early failure.

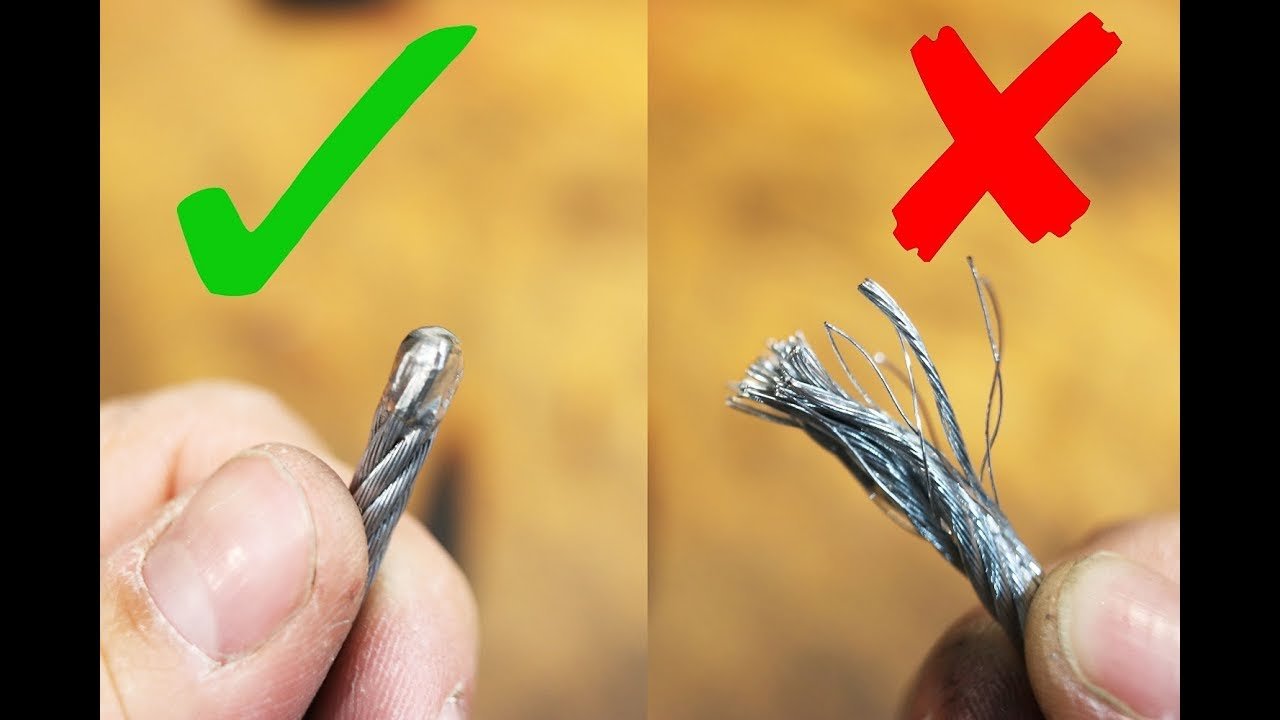

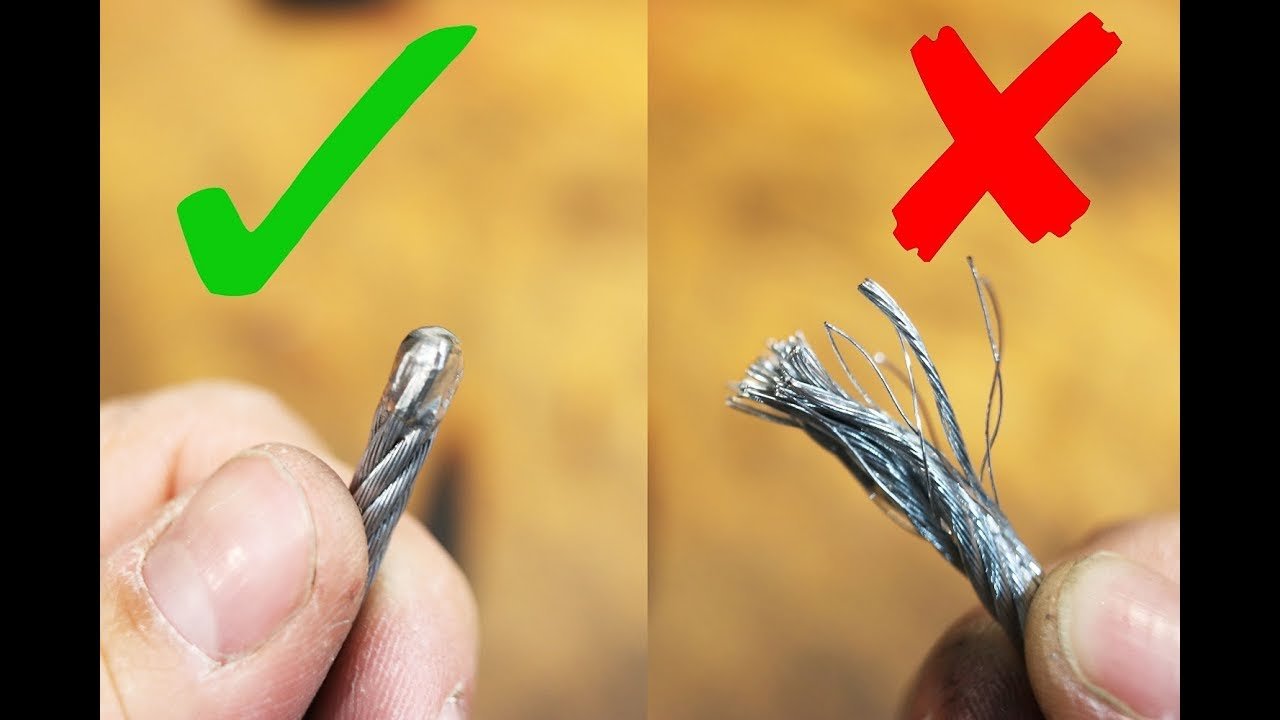

Yes, cutting a wire rope makes it weaker. It breaks the balance of the rope. This causes the individual wires and strands to become unstable. The rope loses its intended strength.

When we make wire ropes, we design them carefully. Each wire and strand works together. They share the load. When you cut a rope, you disrupt this. You expose the core. The ends unravel. This creates weak points.

Understanding Wire Rope Construction:

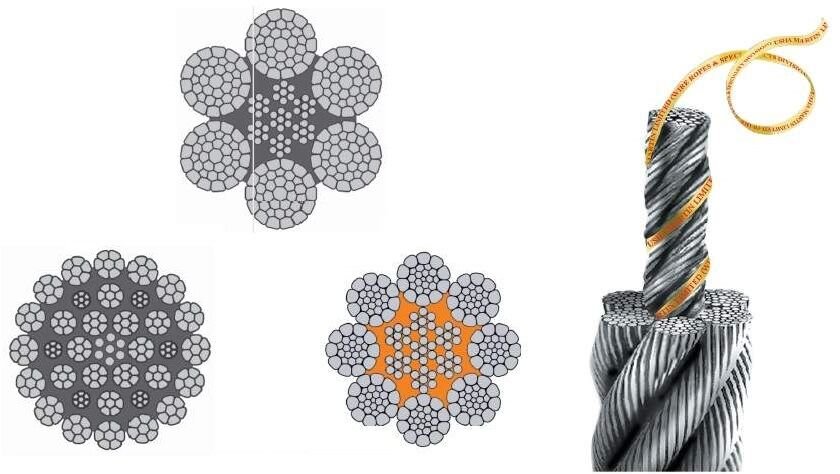

A wire rope is more than just wires twisted together. It is a complex system. It has layers and different parts.

- Core: This is the center. It supports the outer strands. It can be fiber or steel.

- Strands: Wires are twisted around the core. Each strand has many wires.

- Wires: These are the single metal filaments. They make up each strand.

When you cut a rope, you directly cut these components. You break the tension. The individual wires can fray. They can move out of place. This changes how the rope carries a load. It reduces its break load. It reduces its safety.

How Different Cuts Affect Rope Strength:

Not all cuts are the same. But they all reduce safety.

| Type of Cut | Impact on Rope Strength | Risk Level |

|---|---|---|

| Shearing Cut | Crushes the wires. Causes deformation. Weakens uniformly. | High |

| Saw Cut | Creates many small nicks. These are stress points. | Very High |

| Torch Cut | Heats and melts wires. Changes material properties. Very unsafe. | Extreme |

For example, a customer wanted to cut a long crane wire rope. He thought it would save money. But a crane rope needs constant strength. Any cut makes it unsafe. It will fail under load. This can cause big accidents. This risk is not worth the small savings.

When a rope is new, it has a high tensile strength. This means it can handle

much force. It also has a high breaking load. This is the maximum weight it can hold before breaking. Cutting it greatly reduces these values. This makes the rope unsafe for its original use. My factory makes ropes with high quality. We make sure they meet EN12385-4. When you cut them, they no longer meet this standard.

What Are the Dangers of Reusing a Cut Wire Rope?

Reusing a cut wire rope is risky. It can lead to many problems. These affect both safety and cost. It is never a good idea.

Reusing a cut wire rope is very dangerous. It can cause sudden failure. This leads to accidents, injuries, and even death. It can also cause equipment damage and project delays. The risks far outweigh any small benefits.

Imagine a construction site. There is a crane lifting heavy steel. The wire rope looks fine. But it was cut earlier. Suddenly, the rope snaps. The steel falls. People are hurt. Equipment is broken. The project stops. This is the real danger.

Risks Associated with Wire Rope Failure:

Failure of a wire rope has serious consequences.

- Injury and Death: This is the biggest risk. A broken rope can let heavy loads fall. People below can be hit.

- Equipment Damage: Falling loads can destroy cranes, machinery, and other site equipment.

- Property Damage: Surrounding buildings or structures can be damaged.

- Project Delays: Accidents cause projects to stop. This leads to lost time and money.

- Legal Action and Fines: Companies face lawsuits and penalties for unsafe practices.

- Reputation Loss: A company known for accidents loses trust. This hurts future business.

When my team develops wire rope products, we think about all these things. We make sure our ropes are high quality. They have high tensile strength. They have high breaking load. We can provide BV, CE, RMRS, DNV, and ABS certificates. These mean our ropes are safe. But if you cut them, they are no longer safe.

When is it OK to Cut a Wire Rope?

It is only OK to cut a wire rope for disposal. Or if you are making a new assembly. This new assembly must be made by qualified experts. They use special tools. They terminate the ends properly. This maintains the rope’s integrity. It is not just a quick cut with pliers.

For example, we make specialized assemblies. We cut wire ropes for these. But we then process the ends. We use special fittings. This ensures the rope keeps its strength. This is different from a simple field cut.

How Can You Ensure Wire Rope Safety and Longevity?

Ensuring wire rope safety needs careful steps. It starts with buying the right rope. It ends with proper use and inspection.

To ensure wire rope safety, buy high-quality ropes from trusted suppliers. Always use ropes as intended. Perform regular inspections. Replace damaged ropes promptly. Never try to repair or modify a wire rope by cutting it.

I always tell my customers: buy once, buy right. My company, Aulone, makes wire ropes in China. We export to Singapore, Indonesia, and many other countries. We focus on quality. We offer galvanized and plastic impregnated ropes. These offer better protection.

Steps for Safe Wire Rope Use:

Follow these steps to keep your ropes safe.

- Buy Quality: Get ropes from reputable manufacturers. Make sure they have a good reputation. Check for certifications like CE or DNV. We offer them.

- Choose the Right Rope: Match the rope to the job. Consider type, size, and material. For example, maritime ropes need to resist saltwater. Stainless steel wire rope is good for this.

- Proper Installation: Install ropes correctly. Avoid kinks or twists.

- Regular Inspection: Check ropes often. Look for wear, rust, or broken wires.

- Daily Visual Check: Quick scan for obvious damage.

- Weekly Detailed Check: Look closely at entire length, especially end connections.

- Monthly Expert Check: A trained person inspects the rope thoroughly.

- Proper Storage: Store ropes in a dry place. Keep them off the ground. Protect them from extreme temperatures.

- Avoid Overloading: Never use a rope beyond its limit. Know its working load limit.

- Replace Damaged Ropes: If a rope shows any sign of damage, replace it. Do not try to fix it. Do not cut it and reuse it.

- Proper Disposal: Dispose of old or damaged ropes safely. Cut them into small pieces so they cannot be reused.

What to Look for During Inspection:

Regular inspection is key. Here are some signs of damage:

- Broken Wires: Even one broken wire can be a problem.

- Corrosion: Rust weakens the steel.

- Kinks: Permanent bends that distort the rope shape.

- Flat Spots/Abrasion: Rope rubbed against something.

- Reduced Diameter: Ropes can shrink from stress or core damage.

- Heat Damage: Discolored or brittle wires.

Purchasing managers from large companies often ask me about these inspections. They want to make sure their teams are safe. I tell them, investing in good ropes and good training saves money in the long run. It prevents accidents.

Conclusion

Cutting a wire rope and reusing it is extremely dangerous. It makes the rope weaker. It can lead to severe accidents. Always prioritize safety. Buy quality ropes and maintain them well.