Using the wrong wire rope in the sea leads to rust and failure. This can cause terrible accidents and costly downtime. Understanding true marine grade rope is key to safety.

Marine grade wire rope is usually made from Type 316 stainless steel or heavily galvanized carbon steel. These materials resist saltwater corrosion, making them essential for mooring, rigging, and lifting at sea.

I remember a client from Australia who called me in a panic. A rope he bought locally rusted through in months because it wasn’t true marine grade. It’s a common and expensive mistake.

Stainless Steel vs. Galvanized: Which Marine Rope Is Better for You?

Choosing between stainless and galvanized rope can seem hard. But a few key points make the decision easy for your specific needs.

Type 316 stainless steel has the best corrosion resistance and a clean look, great for yachts. Galvanized steel is stronger and cheaper, better suited for heavy industrial marine jobs like towing.

Let’s dive deeper into these two options. Both are good, but they are good for different things. Picking the right one saves you money and prevents problems later.

Dive Deeper: The Details of Each Material

Understanding Type 316 Stainless Steel

This is the top choice for saltwater resistance. It has chromium, nickel, and an important element called molybdenum. Molybdenum is what gives it superior protection against chlorides, like salt.

- Pros: It lasts a very long time in saltwater and always looks good. It doesn’t stain your boat or equipment.

- Cons: It costs more than galvanized steel. For the same size, it also has a slightly lower breaking strength.

I recommend stainless steel for applications where appearance is important, like on luxury yachts, or in situations where the rope is hard to inspect or replace regularly.

Understanding Galvanized Steel

Galvanized wire rope is carbon steel rope that has been dipped in molten zinc. The zinc coating creates a protective barrier against rust. There are different classes of galvanization. For marine use, you want a heavy zinc coating.

- Pros: It is very strong and costs less than stainless steel. The zinc coating gives it good protection against corrosion.

- Cons: The zinc layer can get worn away over time, especially from abrasion. Once the steel is exposed, it will rust.

Galvanized rope is the workhorse for most commercial marine jobs. It’s perfect for mooring lines, crane ropes on docks, and towing applications where high strength is more important than a perfect finish.

Quick Comparison Table

Here is a simple table to help you decide.

| Feature | Type 316 Stainless Steel | Heavily Galvanized Steel |

|---|---|---|

| Corrosion Resistance | Excellent | Good to Very Good |

| Breaking Strength | Good | Excellent |

| Initial Cost | High | Low to Medium |

| Appearance | Bright, clean finish | Dull, metallic finish |

| Best For | Yacht rigging, lifelines, architectural use | Mooring, towing, general lifting |

How Do Construction and Lay Affect a Marine Rope’s Performance?

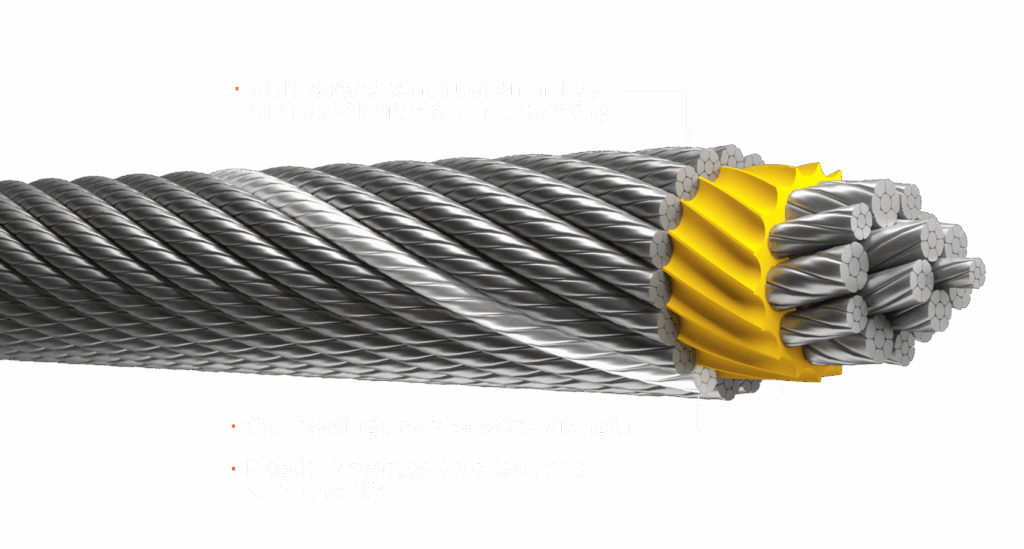

The way a wire rope is built directly changes its flexibility and strength. When you see numbers like 7×19, they tell a story about the rope.

A rope’s construction, like 7×19, shows the number of strands and wires, which changes its flexibility. The lay direction (right or left, regular or lang) affects how the rope acts under load and resists twisting.

It sounds technical, but it’s quite simple. More wires mean more flexibility. The lay just describes the direction the wires are twisted. Let’s look at the most common ones for marine use.

Dive Deeper: Construction and Lay Explained

Common Marine Rope Constructions

The construction description is simple: the first number is the number of strands in the rope. The second is the number of individual wires in each strand.

- 7×7 Construction This rope has 7 strands, and each strand has 7 wires. It is a semi-flexible rope. It’s not as flexible as 7×19, but it has better resistance to abrasion. It is often used for standing rigging or lifelines where it won’t be bent around tight corners.

- 7×19 Construction This rope has 7 strands, with 19 wires in each strand. All those small wires make it very flexible. This is the rope you want for applications where it needs to run over pulleys, like for halyards or steering control cables. Its flexibility comes at the cost of some abrasion resistance.

- ### 6×19 and 6×36 Class Ropes

These are general-purpose ropes used in heavy lifting and mooring. They offer a good balance between flexibility and resistance to wear and tear. They are the standard for many cranes and winches on docks and ships.

Rope Construction Properties

| Construction | Flexibility | Abrasion Resistance | Common Marine Use |

|---|---|---|---|

| 7×7 | Medium | Medium | Stays, lifelines, guy wires |

| 7×19 | High | Low | Halyards, control cables, running rigging |

| 6×19 Class | Medium | High | Mooring, towing, crane hoists |

| 6×36 Class | High | Medium-High | Crane ropes, winch lines |

Regular Lay vs. Lang Lay

This describes how the wires are wrapped.

- Regular Lay: The wires in the strands are twisted in one direction, and the strands are twisted in the opposite direction. This makes the rope stable and easy to handle. It resists crushing on drums well. Most general-purpose ropes are regular lay.

- Lang Lay: The wires and the strands are twisted in the same direction. This makes the rope more flexible and resistant to fatigue from bending. But, it is more likely to untwist under load and should only be used where both ends of the rope are fixed and cannot rotate.

For most marine applications, a right regular lay (RRL) is the standard and safest choice unless an engineer specifies otherwise.

What Certifications Should You Look For When Buying Marine Wire Rope?

A certificate isn’t just paper. It is your guarantee of quality and safety. We take this very seriously at our factory because lives can depend on it.

Always ask for the manufacturer’s test certificate (MTC), which shows the rope’s actual breaking load. Also, check for compliance with international standards like EN12385. For critical jobs, third-party certificates from DNV or ABS are essential.

I once dealt with a case where a customer bought cheap rope without any papers. It failed during a simple lift. The investigation found it wasn’t even close to the strength it was supposed to have. Good certification prevents this.

Dive Deeper: Decoding Rope Certifications

A good supplier will always provide a detailed certificate with every rope they sell. Here is what you need to look for.

The Manufacturer’s Test Certificate (MTC)

This is the most basic document. It should come from the factory that made the rope. It must include:

- Rope diameter and construction

- Material (e.g., Stainless Steel 316, Galvanized Steel)

- Minimum Breaking Load (MBL) or Calculated Breaking Force

- The actual breaking force from a destruction test on a sample from the same production batch.

If a supplier cannot give you an MTC, you cannot trust the rope.

International Standards like EN12385

Standards create a baseline for quality. EN12385 is a key European standard for steel wire ropes. It defines requirements for safety, manufacturing, and testing. Seeing compliance with this standard means the rope was made following strict rules.

Third-Party Type Approval Certifications

For the most demanding marine and offshore applications, you need another layer of trust. This comes from classification societies. They are independent organizations that verify the quality of products used in ships and offshore structures.

Here are some important ones we can provide if a client needs them:

DNV(Det Norske Veritas): Highly respected, especially in the European offshore oil and gas industry.ABS(American Bureau of Shipping): Essential for equipment used on vessels sailing under the American flag.RMRS(Russian Maritime Register of Shipping): Required for many projects in Russia or on Russian-flagged ships.BV(Bureau Veritas): A global leader in testing, inspection, and certification services.CE: This mark shows the product meets EU safety, health, and environmental protection requirements.

When we supply a rope with a DNV certificate, it means a DNV surveyor has inspected our factory and witnessed the testing process. It is the ultimate proof of quality.

Can Plastic Impregnation Extend the Life of Your Marine Rope?

We often get questions about our plastic-filled ropes. It’s a special feature that adds major benefits, especially in sandy or gritty marine environments.

Yes, a plastic-impregnated wire rope will have a longer life in many marine uses. The plastic fills internal spaces, which locks in lubricant, stops internal rust, and reduces friction between wires.

Think of the plastic as a permanent, internal cushion. It keeps the good stuff in (lubricant) and the bad stuff out (salt and sand). This small addition makes a big difference over the rope’s life.

Dive Deeper: The Benefits of a Plastic Cushion

Plastic impregnation is a process where a thermoplastic material is applied to the rope. It fills the empty spaces inside the rope and between the outer strands.

How It Works

- Seals the Core: The plastic creates a barrier that prevents saltwater and abrasive particles like sand from working their way into the core of the rope. Internal corrosion and abrasion are leading causes of rope failure.

- Locks in Lubrication: Every wire rope is lubricated at the factory. The plastic sheath locks this essential lubrication inside, ensuring the core stays protected and the wires can move smoothly against each other.

- Reduces Friction: The plastic acts as a cushion between the strands. This reduces internal friction and wear as the rope bends and flexes.

- Increases Stability: The plastic helps to hold the strands in place, making the rope more stable and resistant to crushing on a winch drum.

Comparison: Standard vs. Plastic Impregnated

| Feature | Standard Galvanized Rope | Plastic Impregnated Galvanized Rope |

|---|---|---|

| Internal Lubrication | Can dry out or be washed out over time. | Lubricant is sealed in for life. |

| Internal Corrosion | Higher risk as moisture and salt get in. | Significantly reduced risk. |

| Abrasion Resistance | Good | Excellent (resists internal and external grit). |

| Fatigue Life | Standard | Improved due to reduced internal friction. |

| Initial Cost | Lower | Higher |

For applications like mooring lines or crane ropes on dredging vessels where sand is a constant problem, a plastic-impregnated rope is a very smart investment. The extra initial cost is often recovered through a much longer service life and fewer replacements.

Conclusion

Choosing the right marine rope means checking its material, construction, and certs. Proper care ensures safety and a long life. If you have questions, we are here to help.