Does your wire rope look worn? Are you worried about its safety? Ignoring signs of wear can lead to serious risks. This is a big problem.

A wire rope is unsafe when wires are broken, strands are deformed, or corrosion is visible. Any sudden change in its appearance means it’s time for a check.

Let me tell you a story. Just recently, one of my team members, let’s call him John, was inspecting a batch of wire ropes. He almost missed a subtle sign. It’s those small details that truly matter. So, let’s dive into how you can spot these signs too.

How do broken wires affect wire rope safety?

Do you see broken wires on your rope? This is a critical issue. Broken wires mean the rope has lost strength and is no longer reliable.

Broken wires reduce a rope’s strength significantly. Even a few broken wires can make a rope fail. This makes the rope unsafe for continued use.

Dive Deeper: Spotting Broken Wires

When I talk about broken wires, people often imagine a huge bundle of snapped strands. But it isn’t always like that. Sometimes, it is just a few small breaks. Those small breaks can lead to big problems.

Here are some common types of broken wires you might see:

Type 1: External Wire Breaks

- Location: These are easy to see. They appear on the outside of the rope.

- Cause: They usually come from bending fatigue or wear against other objects.

- Action: Count them. If you see too many in one section, the rope is unsafe.

Type 2: Internal Wire Breaks

- Location: These are harder to spot. They happen inside the rope.

- Cause: Often caused by internal corrosion or fatigue from continuous bending.

- Action: Look for changes in rope diameter. Feel for lumps or changes in flexibility.

Type 3: Valley Breaks

- Location: These breaks occur where two strands meet.

- Cause: They are often due to contact stresses between strands.

- Action: These are subtle. You might need to look closely at the rope’s contours.

How to Count Broken Wires

Counting broken wires is important. There are rules for this. The number of broken wires allowed depends on the rope’s use and its diameter.

| Rope Diameter (mm) | Max Broken Wires (6d) | Max Broken Wires (30d) |

|---|---|---|

| 8 | 2 | 4 |

| 16 | 4 | 8 |

| 32 | 8 | 16 |

| 64 | 16 | 32 |

6d means in a length of 6 times the rope diameter. 30d means in a length of 30 times the rope diameter.

Remember, these are general guidelines. Always check your specific industry standards. We follow EN12385-4 closely in our factory. This standard helps us ensure quality.

Are deformities in wire ropes a serious concern?

Have you noticed your wire rope changing shape? Deformities are a red flag. They show that parts of the rope are under abnormal stress.

Yes, deformities are a serious concern. They indicate structural damage. This can include kinks, bulges, or flat spots. Such changes mean the rope’s integrity is compromised.

Dive Deeper: Common Deformities and Their Impact

I have seen many deformed ropes. It is always a bad sign. Each type of deformity tells a story about what has gone wrong. Understanding these helps you act fast.

Here are some common deformities:

Type 1: Kinks

- Appearance: This is a sharp bend or twist in the rope.

- Cause: Often happens when the rope is uncoiled improperly. Or it can happen from sudden loads.

- Impact: Kinks permanently damage the rope’s core. They cause severe weakness. The rope’s strength drops sharply.

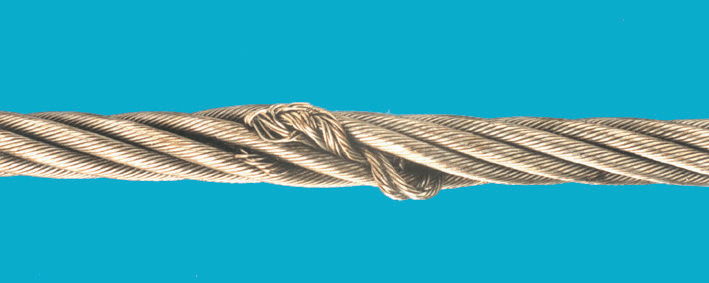

Type 2: Bird Caging

- Appearance: Strands of the rope spread out. They look like a birdcage.

- Cause: This happens with sudden release of tension. Sometimes it is from improper handling.

- Impact: Bird caging means the balance of the rope is gone. The load is no longer shared evenly among strands. This can lead to sudden failure.

Type 3: Core Protrusion

- Appearance: The rope’s inner core pushes out. It can be seen on the outer surface.

- Cause: This happens from excessive loading or torsion.

- Impact: Core protrusion means the rope’s internal structure is failing. It limits flexibility. It also reduces strength.

Type 4: Flattened Sections

- Appearance: Parts of the rope look flat. They are not round anymore.

- Cause: This happens when the rope is squeezed or pressed against something hard.

- Impact: Flattened sections reduce the rope’s load-bearing capacity. They create weak points.

Why You Can’t Ignore Deformities

Deformities are not just cosmetic issues. They are signs of internal damage. When a rope is deformed, its wires and strands are not in their proper place. This means the load is not distributed correctly. This makes the rope much weaker.

I often tell our buyers, like the ones in Singapore or Russia, that a visually sound rope is a safe rope. Any visible change means it is no longer sound.

How does corrosion affect wire rope lifespan and safety?

Is your wire rope showing rust? Corrosion is more than just ugly. It eats away at the metal. It makes the rope weak.

Corrosion severely shortens a wire rope’s lifespan. It weakens the wires and strands. This leads to reduced breaking load. Even light corrosion can hide internal damage and make a rope unsafe.

Dive Deeper: Types of Corrosion and Their Dangers

Corrosion is a silent killer for wire ropes. It gradually eats into the metal. This reduces the rope’s cross-sectional area. It makes the rope less strong.

Here are the main types of corrosion:

Type 1: Surface Rust

- Appearance: This is visible as red or brown patches on the outside.

- Cause: Exposure to moisture and oxygen. Saltwater environments make it worse.

- Impact: Surface rust is the first sign. It can hide deeper problems. It also makes the rope rough. This can damage sheaves or drums.

Type 2: Pitting Corrosion

- Appearance: Small, sharp holes or pits on the wire surface.

- Cause: Localized breakdown of the protective layer. It often happens in specific environments.

- Impact: Pitting corrosion is very dangerous. It causes stress concentrations. This can lead to sudden wire breaks. You might not see it until it is too late.

Type 3: Internal Corrosion

- Appearance: You often cannot see this from the outside. The rope might feel stiff. Or it might show a loss of original lubricity.

- Cause: Moisture gets inside the rope. It can be from faulty lubrication or dirty environments.

- Impact: Internal corrosion is very serious. It eats away at the core and inner wires. This significantly reduces strength without visible signs.

Protecting Your Rope from Corrosion

We use galvanized wire ropes for better corrosion protection. We also offer plastic impregnated ropes. These are designed to fight corrosion.

Here are some ways to help prevent corrosion:

- Proper Lubrication: Keep the rope well-lubricated. This creates a barrier against moisture.

- Regular Inspection: Check for signs of rust often. Act quickly if you see any.

- Clean Environment: Store ropes in dry, clean places. Avoid harsh chemicals.

As a manufacturer from China, we know how important quality is. We provide BV, CE, RMRS, DNV, and ABS certificates if clients need them. This tells you our products meet strict quality standards. This includes corrosion resistance for our galvanized wire ropes.

When should you consider replacing a wire rope?

Are you unsure if your rope needs replacing? Making this decision is crucial. It protects workers and prevents accidents.

You should replace a wire rope immediately if you see severe broken wires, obvious deformities like kinks or bird caging, or heavy corrosion. Also replace it if it passes its useful life or fails inspection parameters.

Dive Deeper: Replacement Criteria and Best Practices

Deciding to replace a wire rope is not just about visible damage. It is also about its history and use.

Quantitative Replacement Criteria

Many standards provide clear numbers for replacement. For example, for a common 6-strand rope:

| Condition | Replacement Trigger |

|---|---|

| Broken external wires | 6 or more random broken wires in 6d length |

| 16 or more random broken wires in 30d length | |

| Broken valley wires | 2 or more valley breaks in 6d length |

| Damaged end connections | Any visible damage, cracks, or severe wear |

| Diameter reduction | More than 7% reduction from nominal diameter |

Note: These are examples. Always refer to the specific standard (e.g., EN12385-4) relevant to your application.

Qualitative Replacement Factors

Some factors are not just about numbers. They need judgment.

- Feel of the Rope: Does it feel stiff? Does it feel crunchy? This can mean internal damage.

- Performance: Is the rope operating smoothly? Are there unusual noises?

- Environment: Is the rope used in harsh conditions? High temperatures, chemicals, or constant flexing can reduce its life faster.

- Loss of Lubrication: If the rope looks dry and rusty inside, it needs to go. Lubrication is key.

The Cost of Delaying Replacement

I understand that procurement managers often face budget limits. But delaying a rope replacement can cost much more.

| Scenario | Immediate Cost (Replacement) | Potential Future Cost (Delay) |

|---|---|---|

| Minor damage | Low | Downtime, repairs, minor accidents |

| Moderate damage | Medium | Major equipment damage, serious injury |

| Severe damage / Catastrophic | High | Fatalities, legal action, brand damage |

One of my Australian clients, Andri, always stressed strict quality control. He knew that the savings from using a slightly damaged rope were nothing compared to the risks. He used to source from top German brands. When he connected with us, he was surprised by our high quality and certifications. We can customize logos and provide necessary certificates. This shows our commitment to safety and quality.

Conclusion

Knowing when a wire rope is unsafe is vital. Look for broken wires, deformities, and corrosion. Always replace damaged ropes to ensure safety and prevent major issues.