When I work on deep shaft projects, I often worry about rope stability, rotation, and breaking load. These problems slow down production and increase risks.

Aulone shaft sinking ropes offer higher breaking loads, better spooling, strong diameter stability, and excellent rotation resistance for deep shaft mining.

I learned these advantages after many field jobs. Each project showed me how rope design affects safety and progress.

Why are these advantages important for shaft sinking?

When I plan shaft sinking work, I always focus on rope performance first. The rope supports the stage and the kibble, so any weakness creates safety issues.

These advantages help control the stage, reduce vibration, avoid rotation, and increase rope life during deep shaft sinking work.

How shaft sinking works

Shaft sinking is the first step in building a deep mine. A stage hangs inside the shaft on two to four ropes. A separate kibble rope lifts people, tools, and muck.

If the ropes rotate or stretch unevenly, the stage becomes unstable. This can damage the hoist and slow down progress.

The main rope types I use

| Rope Type | Role | Why it matters |

|---|---|---|

| Stage rope | Holds the stage | Keeps platform stable |

| Kibble rope | Lifts loads | Needs high breaking load |

| Guide rope | Controls swing | Reduces deviation |

| Safety rope | Backup | Adds protection |

These ropes must work together. If one rope fails, the entire operation becomes unsafe.

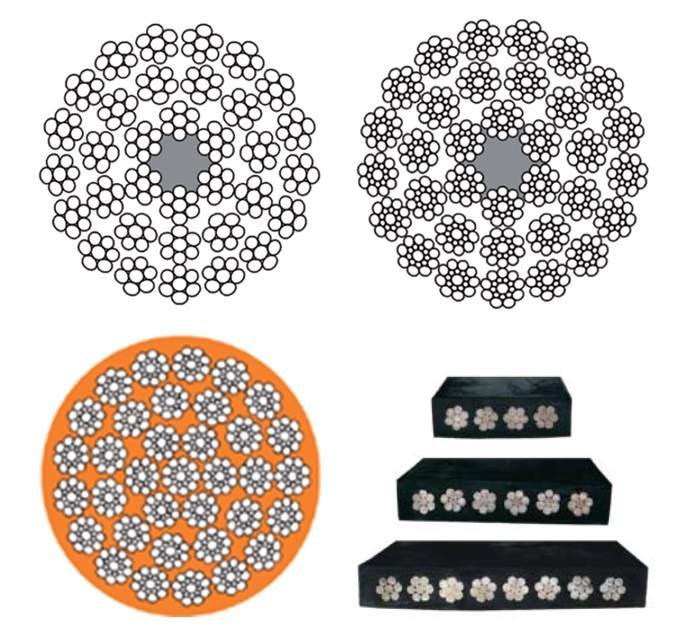

How does compaction improve rope performance?

I use compacted ropes because they offer higher strength and better drum spooling. Compaction presses the strands more tightly.

Compaction increases breaking load, reduces outer wire movement, and improves stability on multi-layer drums.

What compaction changes

Compaction makes the rope smoother and denser. This reduces crushing on the drum and improves contact with the sheaves.

What I notice in practice

- The rope lasts longer

- The rope pulls more weight

- The rope runs smoother

- The rope keeps its diameter better

Compacted vs standard rope

| Feature | Compacted Rope | Standard Rope |

|---|---|---|

| Breaking Load | Higher | Normal |

| Surface | Smooth | Rougher |

| Drum Spooling | Better | Less stable |

| Fatigue | Better | Lower |

This difference becomes clear when I work with deep shaft drums that use many layers.

Why does plastic impregnation (PI) matter so much?

PI is one of the features I value the most. The plastic fills the gaps inside the rope to support the core.

Plastic impregnation improves bend fatigue, enhances internal stability, and protects the core from crushing and corrosion.

How PI helps the rope

The PI layer reduces steel-to-steel contact inside the rope. This lowers friction and slows down internal wear.

What PI improves

| Benefit | Explanation |

|---|---|

| Core life | Less internal wear |

| Bend fatigue | Rope bends more safely |

| Stability | Better diameter control |

| Water resistance | Fewer corrosion problems |

I always choose PI ropes when the hoist uses tight sheaves or runs under high tension.

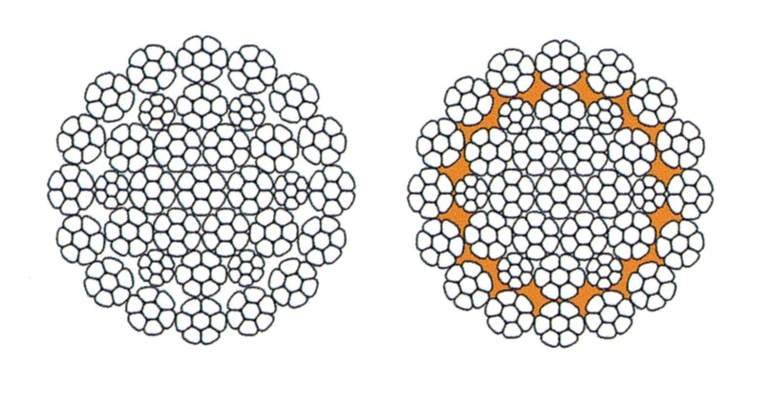

Why do Aulone ropes offer better diameter stability?

Diameter stability is very important for deep shaft hoists. If the rope diameter changes, the rope will not sit correctly on the drum.

Aulone ropes stay round and stable because of compaction, PI, and strong IWRC support.

Why this solves real problems

When high thread pressure builds up, many ropes flatten or change shape. This creates spooling problems.

With Aulone ropes, the diameter stays constant. The rope runs smoothly on the drum, even under heavy tension.

What affects diameter stability

| Factor | Impact |

|---|---|

| IWRC size | Supports the rope core |

| Compaction | Reduces diameter loss |

| PI | Stops distortion |

| Steel grade | Affects strength |

These features keep the rope safe during long operations.

How does rotation resistance improve safety?

Rotation is a big problem in shaft sinking. If a rope twists, it can make the stage tilt or shift.

Aulone’s rotation-resistant designs reduce torque, keep the stage level, and support safer lifting cycles.

Dive Deeper: Why rotation matters

The 35WXK7-EPWSC rope is one of the rotation-resistant designs I use. It uses different layers that cancel each other’s torque.

What rotation-resistant ropes improve

| Benefit | Description |

|---|---|

| Stage stability | Less movement |

| Safety | Fewer accidents |

| Drum spooling | More control |

| Alignment | Keeps shaft equipment centered |

Rotation resistance is essential for deep shafts.

What steel grades do Aulone ropes offer?

In my factory, I produce ropes in 1770, 1860, and 1960 MPa grades. Each grade suits different load requirements.

These grades allow me to match the rope strength with friction hoists, drum hoists, and deep shaft loads.

Why steel grade selection matters

Higher grades increase strength, but the system must support them. I choose based on load, depth, and drum pressure.

Steel grade comparison

| Steel Grade | Strength Level | When I use it |

|---|---|---|

| 1770 | Standard | Light to medium loads |

| 1860 | Strong | Deeper shafts |

| 1960 | Very strong | Heavy loads and high tension |

This flexibility helps me serve different mining systems.

What applications do Aulone shaft sinking ropes support?

I use these ropes in many mining systems. Each system needs stable rope behavior.

Aulone ropes work in friction hoists, drum hoists, Blair hoists, and stage sinking systems.

Why versatility matters

Mining sites often use multiple hoist types. A flexible rope range reduces compatibility issues.

Typical applications

- Tower mounted friction hoists

- Ground mounted friction hoists

- Blair double drum hoists

- Parallel drum hoists

- Stage sinking ropes

I always match rope structure with the hoist design.

What Aulone features help meet mining standards?

I export ropes to many countries. Every order must pass strict checks.

Aulone ropes follow EN12385-4, offer customizable specifications, and support BV, CE, ABS, DNV, and RMRS certification.

How I maintain quality

My factory has four production lines. I test tensile strength, diameter, lay, lubrication, and core condition.

What I control

| Factor | Quality Check |

|---|---|

| Diameter | Laser measurement |

| Breaking load | Pull testing |

| Core condition | X-ray inspection |

| Surface | Visual inspection |

This gives my customers confidence in every shipment.

Conclusion

Aulone shaft sinking ropes give higher strength, better stability, and safer performance.