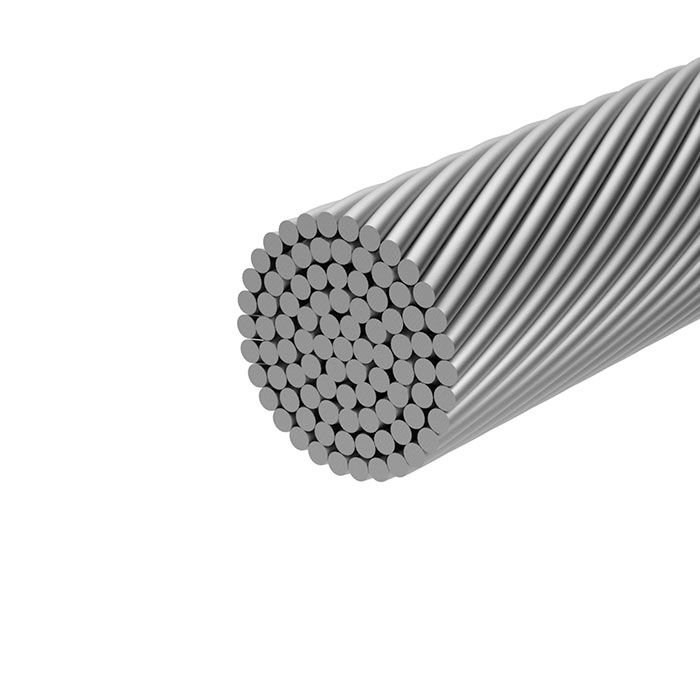

Open Spiral Strand (OSS) is a single, helically wound strand composed entirely of round wires, each with a nominal diameter of 5 mm. In Aulone OSS cables, the wires are protected with a Zinc-Aluminum coating (95% Zn / 5% Al) and an internal zinc-rich paste blocking compound, providing superior corrosion resistance.

High axial stiffness

Excellent strength-to-weight ratio

High fatigue resistance

Torque-balanced design

Three-stage corrosion protection system

Mechanical characteristics of the steel wires:

Nominal Tensile Strength: 1570 MPa (after hot-dip galvanizing)

Proof Stress Rp 0.2: 1180 MPa

Elongation at Break: ≥4% on 250 mm (EN 12385-10)

Modulus of Elasticity: 160 ± 10 kN/mm²

Description

Aulone Open Spiral Strands (OSS) are manufactured using helically wound, hot-dip galvanized high-strength steel round wires, typically spun in opposite directions around a central core. Each wire undergoes rigorous testing to ensure tensile strength, ductility, elongation at fracture, bending and torsional performance, as well as zinc coating adhesion, in accordance with EN 10264 and EN 12385-10.

The resulting OSS cables deliver high axial stiffness, exceptional strength-to-weight ratio, superior fatigue resistance, and torque-balanced performance for demanding industrial applications.

Aulone OSS cables are ideal for heavy-duty lifting, mining, crane operations, and other environments requiring high-performance wire ropes where strength, durability, and corrosion resistance are critical.

| Nominal Diameter | Minimum Breaking Loads | Charact. Breaking Load | Design Load | Nom. Metallic Cross Section | Stiffness | Weight |

|---|---|---|---|---|---|---|

| [mm] | [kN] | [kN] | [kN] | [mm2] | [MN] | [kg/m] |

| 6 | 37.7 | 33.9 | 22.6 | 22.0 | 3.52 | 0.2 |

| 8 | 67.5 | 60.7 | 40.5 | 39.4 | 6.31 | 0.3 |

| 10 | 105 | 94.4 | 62.9 | 61.3 | 9.81 | 0.5 |

| 12 | 150 | 135 | 90.3 | 87.9 | 14.1 | 0.7 |

| 14 | 204 | 184 | 123 | 119 | 19.1 | 1.0 |

| 16 | 266 | 240 | 160 | 156 | 24.9 | 1.3 |

| 18 | 331 | 298 | 199 | 198 | 31.6 | 1.6 |

| 20 | 408 | 368 | 245 | 244 | 39.0 | 2.0 |

| 22 | 494 | 445 | 297 | 295 | 47.3 | 2.4 |

| 24 | 591 | 532 | 355 | 353 | 56.5 | 2.9 |

| 26 | 693 | 624 | 416 | 414 | 66.3 | 3.4 |

| 28 | 792 | 713 | 475 | 479 | 76.6 | 3.9 |

| 30 | 907 | 816 | 544 | 548 | 87.7 | 4.5 |

| 32 | 1034 | 931 | 620 | 625 | 99.9 | 5.1 |

| 34 | 1169 | 1052 | 702 | 706 | 113 | 5.8 |

| 36 | 1298 | 1168 | 779 | 793 | 127 | 6.5 |

| 40 | 1450 | 1450 | 967 | 929 | 149 | 7.7 |

| 45 | 1830 | 1830 | 1220 | 1180 | 189 | 9.8 |

| 50 | 2260 | 2260 | 1507 | 1450 | 232 | 12 |

| 55 | 2730 | 2730 | 1820 | 1750 | 280 | 15 |

| 60 | 3250 | 3250 | 2167 | 2090 | 334 | 17 |

| 65 | 3810 | 3810 | 2540 | 2450 | 392 | 20 |

| 70 | 4430 | 4430 | 2953 | 2840 | 454 | 24 |

| 75 | 5080 | 5080 | 3387 | 3260 | 522 | 27 |

| 80 | 5790 | 5790 | 3860 | 3710 | 594 | 31 |

| 85 | 6530 | 6530 | 4353 | 4190 | 670 | 35 |

| 90 | 7320 | 7320 | 4880 | 4700 | 752 | 39 |

| 95 | 8160 | 8160 | 5440 | 5240 | 838 | 44 |

| 100 | 9040 | 9040 | 6027 | 5800 | 928 | 48 |

| 105 | 9990 | 9990 | 6660 | 6400 | 1024 | 53 |

| 110 | 10900 | 10900 | 7267 | 7020 | 1123 | 58 |

| 115 | 12000 | 12000 | 8000 | 7680 | 1229 | 64 |

| 120 | 13000 | 13000 | 8667 | 8360 | 1338 | 69 |

| 125 | 14100 | 14100 | 9400 | 9060 | 1450 | 75 |

| 130 | 15300 | 15300 | 10200 | 9810 | 1570 | 81 |

| 135 | 16500 | 16500 | 11000 | 10600 | 1696 | 88 |

Kaiyuan road 36,Chunkou,Liuyang, Hunan,China.

info@steelwireropes.cn

admin@steelwireropes.cn

Phone : +86 15573139663

WhatsApp : +86 15573139663

Expert guidance on wire rope specifications and applications

WhatsApp us

Free samples, product catalog, and expert consultation available.