Spiral strand cables are high-strength steel wire ropes engineered for structural stability, load-bearing applications, and minimal elongation. Composed of cold-drawn galvanized or stainless steel wires helically wound in one or more layers around a core, these cables offer exceptional tensile strength, corrosion resistance, and durability.

Spiral strand cables are precision-engineered steel wire ropes designed for superior structural integrity, high load-bearing capacity, and low stretch performance. They are constructed by helically winding cold-drawn galvanized or stainless steel wires in one or more layers around a central core. This design delivers outstanding tensile strength, excellent corrosion resistance, and long-term durability, making them ideal for demanding static and semi-static applications.

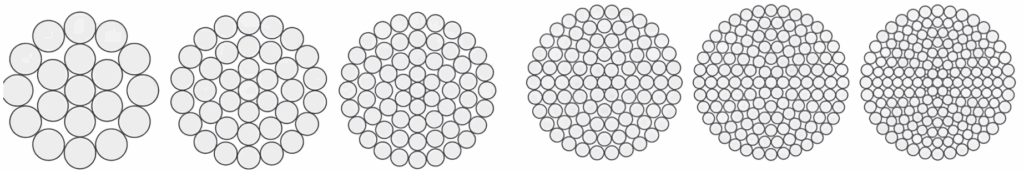

Spiral strand cables are composed of multiple layers of high-tensile steel wires helically wound around a central core wire. This geometric arrangement provides excellent axial alignment, uniform stress distribution, and high strength.

Core Wire (Center Wire):

The innermost wire that serves as the backbone of the cable.

Typically the same diameter and material as the outer wires.

First Layer of Helical Wires:

Wound tightly around the core in a single helical direction (either right-hand or left-hand lay).

This 1+6 structure (one core + six outer wires) forms the simplest spiral strand.

Multiple Layers (Optional):

For increased strength and larger diameters, additional layers of wires are wound concentrically over the first layer.

Each layer is laid in the same helical direction to maintain strand stability.

Wire Material and Finish:

Usually made of cold-drawn high-carbon steel, galvanized steel, or stainless steel.

Surface finishes may include zinc, aluminum-zinc alloy, or polymer coatings for enhanced corrosion resistance.

1×7 (1+6) – Basic structure for small-diameter strands.

1×19 (1+6+12) – Common for medium-duty structural applications.

1×37 , 1X61, 1X91 or higher – Used for large-span bridges, towers, and other heavy-load structures.

Spiral strand cables are usually laid in a single uniform direction (e.g., right-hand lay), unlike regular ropes where layers alternate directions to reduce torque.

The consistent lay direction ensures better performance under tension in static systems.

High strength-to-weight ratio

Low elongation under load

Excellent fatigue and corrosion resistance

Precision-manufactured for dimensional stability

Available in galvanized, aluminized, or stainless steel

Bridge suspension and stay cables

Guy wires and mast stays

Structural support in stadiums, towers, and roofs

Cable barriers and railings

Offshore mooring and anchor lines

Wind turbine supports

Crane pendants and heavy lifting systems

Spiral strand cables can be manufactured to meet international standards such as EN 12385, ASTM A586, or BS 183, with options for:

Diameter ranges from a few millimeters to over 100mm

Zinc/aluminum coatings for long-term corrosion protection

End terminations (socketing, swaging, etc.)

Tensile grades from 1,570 MPa to 1,960 MPa or higher

Kaiyuan road 36,Chunkou,Liuyang, Hunan,China.

info@steelwireropes.cn

info@wireropes.net

Phone : +86-15573139663

WhatsApp : ++86-15573139663

Get help choosing the right wire rope — fast, safe, certified.

WhatsApp us

Fill out a quick form to get a personalized quote tailored to your specific needs.

Note: Your email information will be kept strictly confidential.