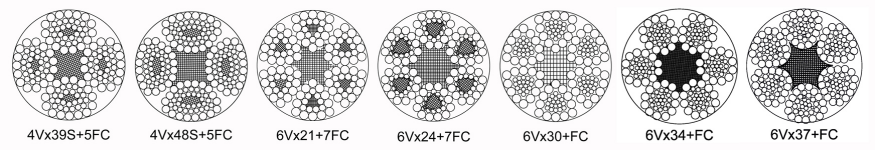

Shaped Strand Wire Rope is a specialized type of wire rope designed for heavy-duty applications where high strength, durability, and reduced internal friction are critical. Unlike conventional round strand ropes, shaped strand ropes feature strands that are flattened or shaped, allowing for better packing and increased contact surface between strands. This design provides superior performance in demanding mechanical and industrial environments.

Enhanced Strength and Load Capacity

Shaped strands provide more contact points and reduce gaps between wires, which increases the rope’s overall breaking strength and load-bearing capability.

Reduced Internal Friction

By shaping the strands, internal wire-to-wire friction is minimized, reducing wear and extending the rope’s service life, even under continuous heavy loading.

Better Fatigue Resistance

The distribution of stress across shaped strands lowers the risk of broken wires, making these ropes more fatigue-resistant than standard round strand ropes.

Improved Spooling and Handling

Shaped strands maintain their profile under pressure, allowing the rope to spool more neatly on drums and sheaves without birdcaging or uneven layering.

Long Service Life

The combination of high strength, low friction, and excellent wear resistance ensures a longer operational lifespan, reducing maintenance and replacement costs.

Shaped strand wire ropes are widely used in industries where high performance and reliability are critical:

Mining and Heavy Lifting: Hoist ropes, draglines, and dragline excavators.

Marine and Offshore: Mooring lines, winches, and cranes.

Construction: Tower cranes, elevators, and large-scale lifting equipment.

Industrial Machinery: Conveyors, heavy-duty machinery, and equipment requiring precise rope movement.

Galvanized or Stainless Steel: For corrosion resistance in harsh environments.

Plastic Impregnated (PIW) or Plastic Coated: To provide lubrication, protect against abrasion, and reduce maintenance.

Non-Rotating or Rotation-Resistant Designs: For applications requiring minimal rope twist under load.

Shaped strand wire ropes are manufactured according to international standards such as EN 12385, ISO 2408, and DIN 3060, ensuring consistent quality, strength, and safety. Third-party testing and certification can also be provided to meet specific project or industry requirements.

Kaiyuan road 36,Chunkou,Liuyang, Hunan,China.

info@steelwireropes.cn

admin@steelwireropes.cn

Phone : +86 15573139663

WhatsApp : +86 15573139663

Expert guidance on wire rope specifications and applications.

WhatsApp us

Free samples, product catalog, and expert consultation available.