Are you tired of unexpected equipment failures? Do you struggle with finding the perfect wire rope? This guide helps you choose the right one.

Selecting the right wire rope means matching its high-quality features, such as breaking load and material, to your specific application’s needs for safety and performance.

My journey in the wire rope industry has taught me a lot. I’ve seen many projects succeed or fail based on this one choice. Let me share what I’ve learned.

Why is choosing the right wire rope crucial for safety and performance?

Choosing the right wire rope is critical. It directly impacts safety. It also affects equipment performance. A wrong choice can lead to accidents. It can also cause costly downtime.

The right wire rope ensures operational safety, maximizes equipment lifespan, and optimizes performance by matching its strength, durability, and type to the specific demands of lifting, hoisting, or pulling tasks.

Choosing the right wire rope is more than just picking a size. It requires careful consideration. It protects your team. It also protects your investment. A recent client, let’s call him Alex, faced frequent rope breakages. His company imported materials. He needed reliability. We discussed his specific challenges. He valued both pricing and quality. He also had strict certification needs. We found a solution. It met his needs.

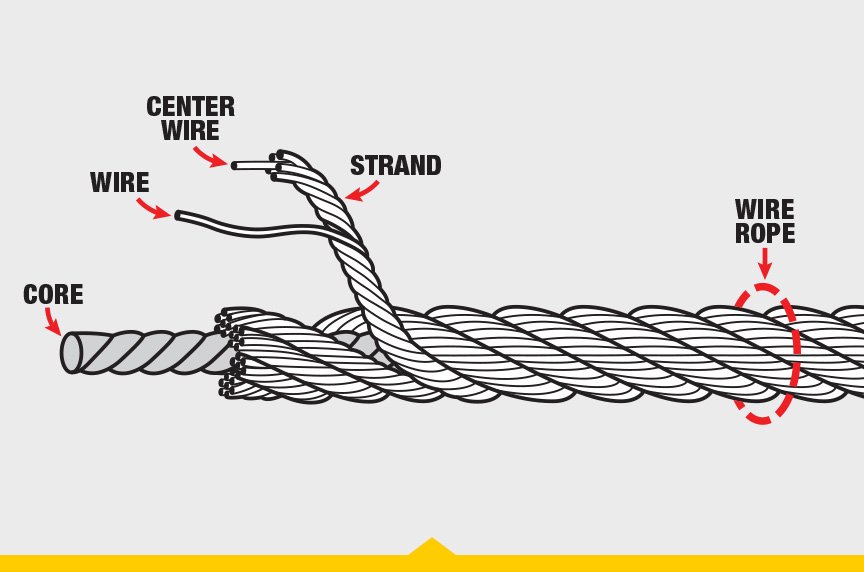

Understanding Wire Rope Types

Wire ropes come in many types. Each type has a specific design. It also has a specific purpose.

- Fiber Core (FC) Ropes: These ropes are flexible. They are good for general use. They have lower crushing resistance.

- Independent Wire Rope Core (IWRC) Ropes: These ropes are strong. They resist crushing. They offer better stability. They are suitable for heavy-duty work.

Key Factors to Consider

Many factors influence your choice.

- Application: What will the rope be used for? Is it for lifting, pulling, or anchoring?

- Breaking Load: What is the maximum weight the rope must hold?

- Tensile Strength: How much force can the rope withstand before breaking?

- Fatigue Resistance: How well does the rope withstand repeated bending over sheaves?

- Corrosion Resistance: Will the rope be exposed to moisture or harsh chemicals? Galvanized or stainless steel options might be needed.

Certification and Standards

Certifications are important. My facility follows strict standards. It produces high-quality ropes. We offer various certifications. These include EN12385-4. We can also provide BV, CE, RMRS, DNV, and ABS. These ensure compliance. They guarantee reliability.

Customization Options

Sometimes, standard ropes are not enough. We offer customization.

- Plastic Impregnated: This enhances durability. It protects core wires.

- Galvanized: This provides corrosion resistance. It extends rope life in wet environments.

- Customizable Logo: We can add your logo. This is good for branding.

How do materials and construction affect wire rope performance?

The materials used are crucial. The way a wire rope is constructed also matters. These directly affect its performance. They determine its strength. They also determine its durability.

Materials like high-grade steel provide strength, while construction methods like the number of strands and lay pattern impact flexibility, internal friction, and resistance to rotation, directly influencing a wire rope’s performance in specific applications.

Material and construction are tied together. They define the rope’s capabilities. Consider a client who operates cranes. He needs ropes with high breaking loads. He also needs ropes that resist wear. We suggest ropes made from strong steel. These ropes also have a specific construction. This construction reduces fatigue. It ensures their safe operation.

Material Choices

Different materials offer different benefits.

- Carbon Steel: This is common. It provides high strength. It is cost-effective.

- Stainless Steel: This resists corrosion. It is ideal for marine environments. It is also good for chemical industries.

- High-Tensile Steel: This provides superior strength. It is used for heavy lifting.

- Synthetic Fibers: These are newer. They are lightweight. They resist corrosion. They are good for specialized applications.

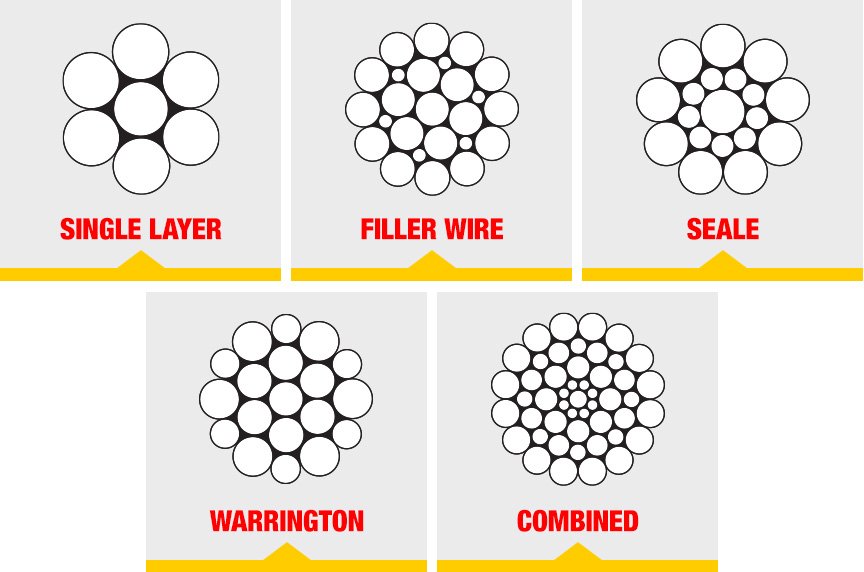

Construction Types

Wire rope construction varies widely.

- Number of Strands: More strands usually mean more flexibility. Common numbers are 6, 8, 19, or 35.

- Number of Wires per Strand: This affects strength and fatigue life.

- Lay Direction (Regular vs. Lang Lay):

- Regular Lay: Wires in the strand lay opposite to strands in the rope. This is common. It resists twisting.

- Lang Lay: Wires in the strand lay the same direction as strands in the rope. This offers better fatigue resistance. It has more flexibility. It can be prone to twisting.

- Core Type:

- Fiber Core: Offers flexibility. Less strength.

- Independent Wire Rope Core (IWRC): Offers more strength. It resists crushing. It is less flexible.

Benefits of Specific Features

Certain features enhance performance.

- Plastic Impregnation: We offer plastic impregnation. This fills internal voids. It reduces internal wear. It extends the rope’s life.

- Galvanized Wire Rope: This process adds a zinc coating. It protects against rust. It is essential for outdoor use. It is crucial for marine environments.

What quality standards should you look for in wire rope manufacturers?

Quality standards are very important. They ensure product reliability. They also guarantee safety. You must look for these standards.

You should look for manufacturers compliant with international standards like EN12385-4, holding certifications such as BV, CE, RMRS, DNV, or ABS, and who offer high breaking loads and traceable quality control processes to ensure product excellence.

Trust is built on quality. I have seen how poor quality can jeopardize projects. Our commitment to high standards is unwavering. We follow strict procedures. This ensures every rope meets top requirements. My factory has four production lines. We export to many countries. These include Singapore, Indonesia, and Australia. Our quality speaks for itself.

Essential Quality Certifications

Many certifications exist.

- EN12385-4 Compliant: This is a European standard. It specifies requirements for steel wire ropes for general lifting.

- BV (Bureau Veritas): This is a global leader. It provides testing and certification services.

- CE (Conformité Européenne): This mark indicates conformity. It meets health, safety, and environmental protection standards.

- RMRS (Russian Maritime Register of Shipping): This is for maritime use. It covers ships and offshore structures.

- DNV (Det Norske Veritas): This is another maritime standard. It ensures safety and quality.

- ABS (American Bureau of Shipping): This is for ships and marine structures too.

High-Quality Manufacturing Practices

A good manufacturer has robust practices.

- High Tensile Strength: Our ropes are designed for high strength. This ensures they can handle heavy loads.

- High Breaking Load: We test for breaking load. This guarantees safety margins.

- Strict Quality Control: Every batch undergoes rigorous testing. This maintains consistency. It prevents defects.

- Traceability: We can trace every product. This applies from raw material to final shipment. This ensures accountability.

Customization and Service

Good manufacturers offer more than just products.

- Customizable Logo: We offer branding options. This helps distributors.

- Specialized Assemblies: We produce specialized assemblies. These meet unique project needs.

- Customer Support: We provide excellent support. We guide clients through the selection process. We help address pain points. This includes pricing and certifications.

Conclusion

Choosing the right wire rope is crucial. It requires understanding features and standards. Prioritize quality and relevant certifications for safety.