Are you tired of guessing which steel wire rope you need? Do you worry about failures and costly downtime? What if there was a simple way to choose the perfect one?

Choosing the right steel wire rope depends on its intended use, breaking load, and the specific environment. Match these factors for safety and efficiency.

I once had a conversation with a buyer from Australia. He was struggling with finding reliable suppliers. He even had issues with pricing and getting the right certifications. This made me think about how complex selecting wire rope can be.

What Factors Must You Consider When Choosing Steel Wire Rope?

Choosing wire rope is not simple. Many things affect its performance. You need to think about more than just the price.

When selecting steel wire rope, key factors include application-specific needs, material type, construction, breaking strength, and environmental conditions like corrosion or temperature.

Dive Deeper: Understanding the Key Selection Criteria

Let’s look closer at what goes into making the right choice. It is about understanding the details.

Application and Purpose

First, think about what the rope will do. Is it for a crane? Is it for mining? Every use has different needs.

- Lifting: Cranes need ropes with high breaking loads. They also need good fatigue resistance.

- Stationary: Ropes used for staying in place, like bridge supports, need high strength and corrosion resistance.

- Marine Use: Ropes in marine environments need excellent resistance to saltwater. This means galvanized or stainless steel types.

<br>

| Application Type | Key Properties Needed | Common Rope Types |

|---|---|---|

| Cranes | High breaking strength, Fatigue resistance | Compacted, Rotation resistant |

| Elevators | Smooth operation, High safety factor | Non-rotating, Plastic impregnated |

| Mining | Abrasion resistance, High strength | Large diameter, Tough construction |

| Marine | Corrosion resistance, Durability | Galvanized, Stainless steel |

<br>

Material Type

The material affects strength and resistance.

- Carbon Steel: Strong and good for general use. It is common.

- Galvanized Steel: This has a zinc coating. It protects against rust. It is good for wet places.

- Stainless Steel: This has excellent corrosion resistance. It is perfect for harsh chemical or marine settings.

<br>

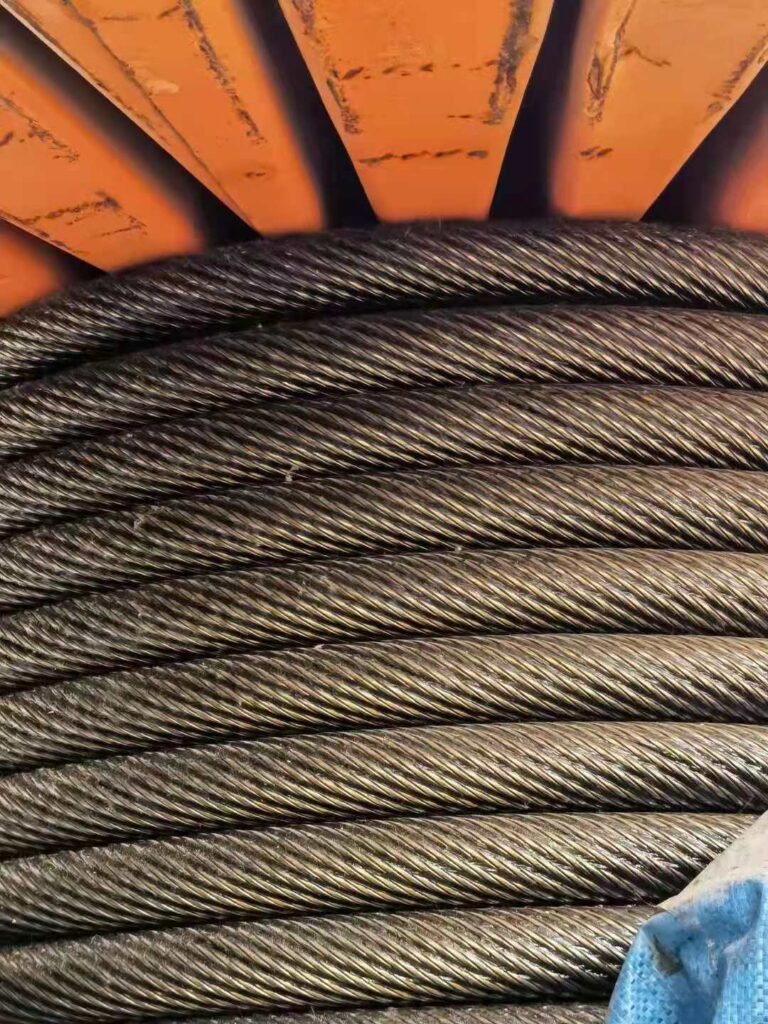

Rope Construction

This refers to how the wires are twisted. Different constructions have different properties.

- 6×19 Class: This is versatile. It offers a good balance of strength and flexibility.

- 6×36 Class: This is more flexible than 6×19. It is good for drums and sheaves.

- Rotation Resistant Ropes: These are designed to reduce twisting. They are good for single-part lines.

| Construction Type | Characteristics | Typical Uses |

|---|---|---|

| 6×19 (FW) | Good balance of strength and flexibility | General purpose, Slings |

| 6×36 (WS) | More flexible, Higher fatigue life | Hoisting, Crane ropes |

| 19×7 | Rotation resistant | Single-part lines, Overhead cranes |

| 35×7 | Highly rotation resistant | Mobile cranes, Tower cranes |

Breaking Load and Safety Factor

Every rope has a maximum load it can take before breaking. This is its breaking load. You must never exceed this. A safety factor is also important. This is a ratio. It helps to ensure the rope does not fail. For example, a crane rope might need a safety factor of 5:1. This means the breaking load is five times the maximum working load.<br>

Environmental Conditions

Where will the rope be used?

- Temperature: Extreme heat or cold can affect rope strength. Some ropes are designed for high temperatures.

- Abrasion: If the rope rubs against things, it needs good abrasion resistance.

- Corrosion: Water, chemicals, or salt can cause rust. galvanized or stainless steel ropes are best in these cases.

- Dirt/Dust: Dirt can get into the rope. This can cause wear. Regular cleaning helps.

By thinking about these points, you can narrow down your choices. This helps you select a rope that performs best.

Why Are Certifications and Quality Control So Important?

Some buyers, like the one from Australia, care a lot about certifications. He worked with top German brands before. He knew the value of strict quality control.

Certifications like EN12385-4, BV & CE, RMRS, DNV, and ABS ensure a wire rope meets international safety and performance standards, verifying quality and reliability.

Every wire rope must meet certain standards. These standards ensure safety and performance. We make sure our ropes comply with EN12385-4. This is a key standard in Europe. It shows our dedication to quality. We can also provide other certificates if you need them. These include BV & CE, RMRS, DNV, and ABS. These certifications are proof. They show our ropes are made to high standards. They also show they will perform well.

Can Customization Help You Get the Right Wire Rope?

Sometimes, a standard rope is not enough. You might need something special. Maybe a different length, strength, or coating.

Yes, customization helps by providing specific lengths, strengths, or coatings, making the wire rope perfect for unique applications that standard options cannot fulfill.

We understand that every project is unique. This is why we offer customization. We can add your logo. We can also provide plastic impregnation or galvanization. This allows you to get a rope that fits your exact needs.

What Makes Aulone Different from Other Wire Rope Suppliers?

Choosing a supplier is as important as choosing the rope. You need a partner you can trust.

Aulone stands out due to its high-quality products, high tensile strength, excellent breaking load, compliance with EN12385-4, and the ability to provide various necessary certifications.

We are a factory in China. We have four production lines. This means we can produce a lot. We export to many countries. These include Singapore, Indonesia, Vietnam, Saudi Arabia, UAE, Russia, Australia, and Canada. Our products are high quality. They have high tensile strength. They also have a high breaking load. We also focus on customer service. We work closely with our clients. We want to ensure they get the right rope. This is how we build long-term relationships.

Conclusion

Choosing the right steel wire rope requires careful thought. Consider its use, material, and required strength. Certifications and customization also play a big part.