Basic Construction

A round strand wire rope typically follows this structure:

Wires: Small-diameter steel wires.

Strands: Groups of wires twisted together (e.g., 6, 8, 19 strands).

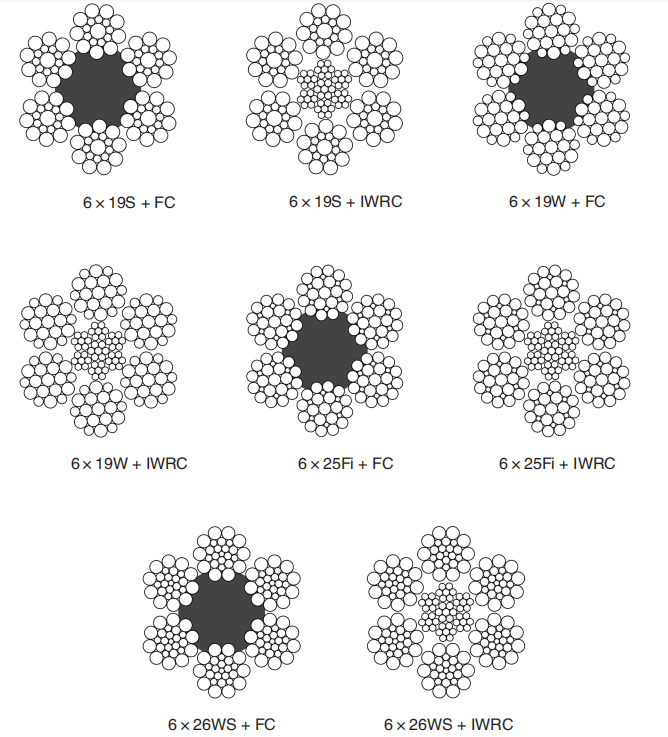

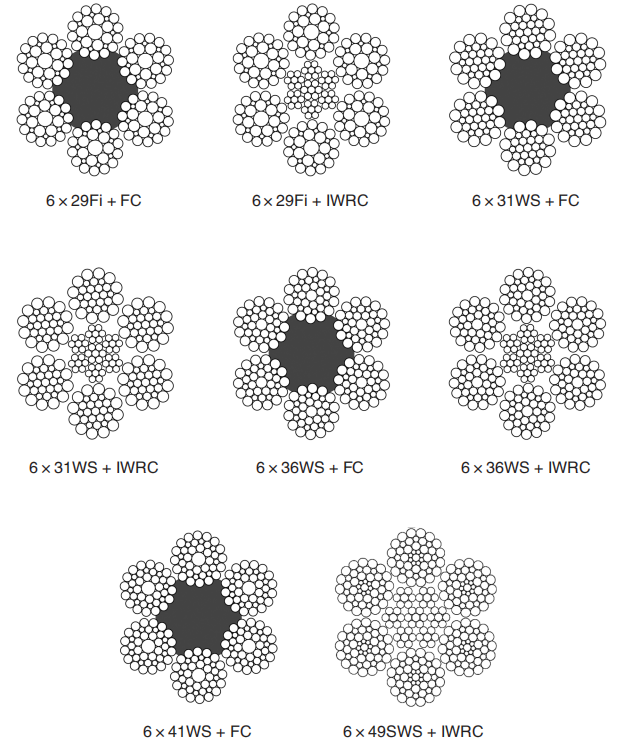

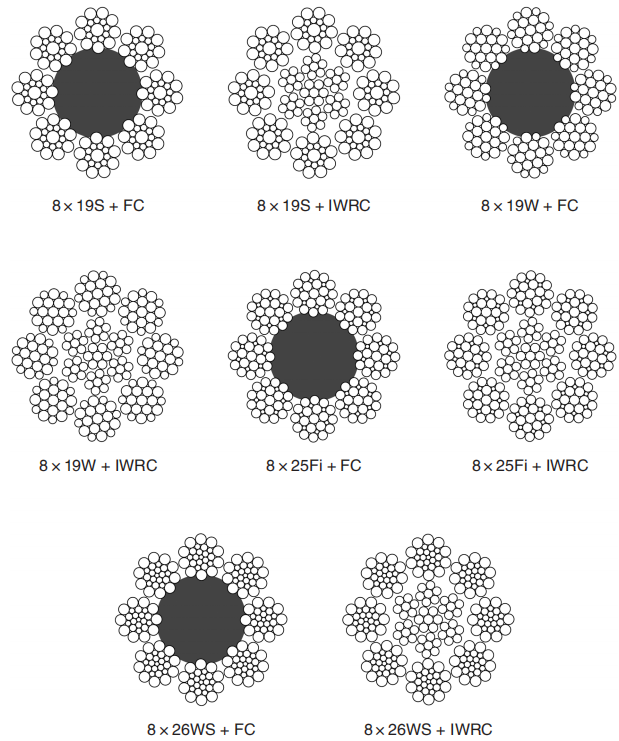

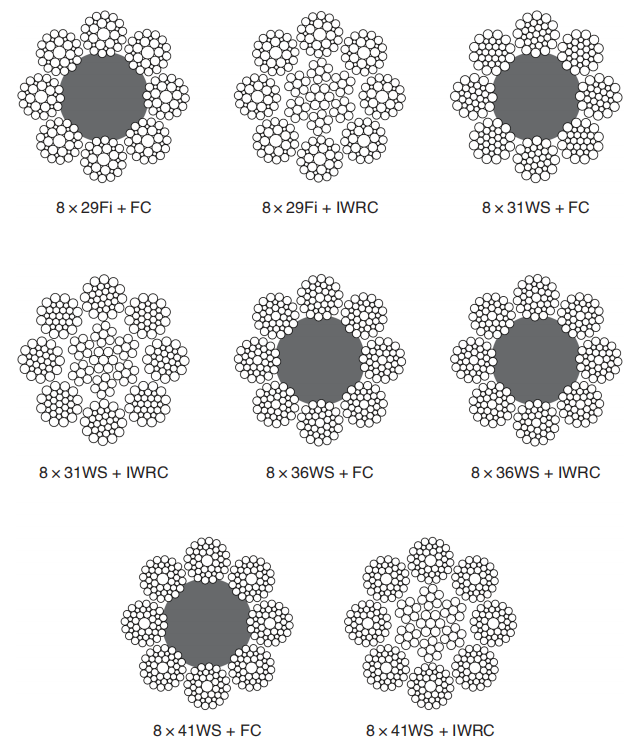

Core:

Fiber Core (FC): More flexible, but less crush-resistant.

Independent Wire Rope Core (IWRC): Higher strength and resistance to crushing.

Common Configurations

6×19: 6 strands with 19 wires per strand – Good balance of flexibility and abrasion resistance.

6×36: 6 strands with 36 wires per strand – More flexible, less abrasion-resistant.

8×19 or 8×36: Used in applications needing more flexibility and smoother operation.

19×7 or 35×7: Rotation-resistant round strand ropes, often used in crane hoist applications.

Key Features

Shape: Traditional round cross-section.

Flexibility: Depends on wire diameter and number of wires per strand (more wires = more flexible).

Abrasion Resistance: Fewer, thicker wires = more abrasion resistance.

Fatigue Resistance: More, thinner wires = better resistance to bending fatigue.

Strength: Determined by steel grade and construction (e.g., 1770 MPa or 1960 MPa tensile strength).

Applications

Cranes and Hoists

Elevators and Winches

Marine and Offshore Mooring

Logging and Mining

General Lifting and Rigging

Construction Machinery

Surface Finishes

Bright: Untreated steel wire.

Galvanized: Zinc-coated for corrosion resistance.

Plastic-Coated: Additional protection and smoother handling.

Selecting the Right Round Strand Rope

When choosing a round strand wire rope, consider:

Load requirements (breaking strength, safety factor)

Working environment (abrasion, corrosion, temperature)

Flexibility vs. durability trade-offs

Certifications (EN, ISO, API, etc.)