Non-rotating wire rope, also known as rotation-resistant wire rope, is a specialized type of wire rope designed to minimize or eliminate the rope’s tendency to rotate under load. This is achieved through a unique construction of multiple layers of strands, where the outer and inner layers are wound in opposite directions. The torque generated by one layer is counteracted by the torque of another, resulting in exceptional stability during lifting operations.

Non-rotating wire rope, also known as rotation-resistant wire rope, is a specialized type of wire rope designed to minimize or eliminate the rope’s tendency to rotate under load. This is achieved through a unique construction of multiple layers of strands, where the outer and inner layers are wound in opposite directions. The torque generated by one layer is counteracted by the torque of another, resulting in exceptional stability during lifting operations.

Non-rotating ropes typically have two or three layers of strands. Common configurations include:

35WXK7: A 35-strand, multi-layer design with 7-wire strands per layer, offering superior rotation resistance and flexibility.

19X7: A basic two-layer rope, used in general lifting operations but with lower rotation resistance than 35WXK7.

18X7+IWRC or 19X19: Mid-tier options providing balance between rotation resistance and strength.

For added performance, these ropes can be:

Plastic-coated (EPIWRC) between core and outer strands to reduce internal wear.

Galvanized for enhanced corrosion resistance in marine or outdoor applications.

Compacted to improve strength and smoothness.

Lubricated during manufacture to extend service life.

✅ High rotation resistance – ideal for single-line lifting and high-lift operations.

✅ Reduced risk of rope spinning or load rotation – improves safety and load control.

✅ Excellent flexibility and fatigue resistance, especially in high-cycle applications.

✅ Longer service life due to improved internal structure and materials.

Non-rotating wire ropes are used in critical lifting scenarios where stability and safety are paramount:

Tower cranes

Mobile cranes

Overhead cranes

Offshore and marine winches

Elevators

Hoisting in mines and deep shafts

Rotary drilling rigs

Aulone’s non-rotating wire ropes meet strict quality control standards, including:

ISO and CE, BV, ABS, DNV, RMRS, SGS certifications

Support for third-party inspection

Custom specifications available per project needs

Factory-tested for tensile strength, torsion, bend fatigue, and elongation

At Aulone, we prioritize performance, safety, and consistency. Our non-rotating ropes are produced using high-precision German equipment (GPL037), achieving up to 30% improved dimensional tolerance. Every batch undergoes rigorous testing and traceable quality control, ensuring our customers receive reliable and certified products for the toughest jobs.

Whether you’re lifting 10 meters or 300 meters, let us help you select the right non-rotating wire rope for your application. Contact our technical team to learn more or request a free consultation and quotation.

Professional Service That Supports Your Business

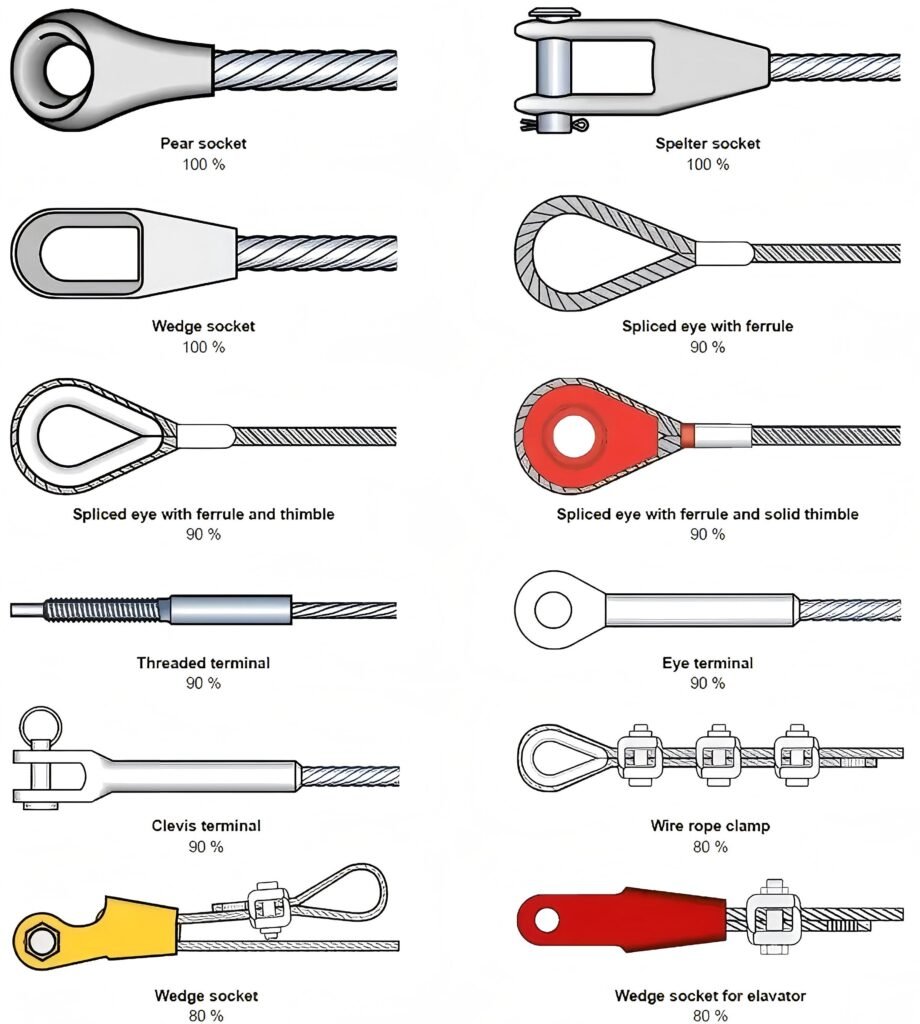

We provide custom socket and end termination solutions for lifting, mooring, marine, and structural use.

Available Types:

– Closed / Open sockets (with or without pin)

– Spelter sockets (resin type)

– Swaged sockets (mechanically pressed)

– Threaded ends

– Thimble eyes / Soft eyes / Flemish eyes

– DIN / BS / G standard options

Customization:

– Fits your rope diameter & load grade

– Galvanized or painted finish

– Logo, stamping, or serial marking on request

Kaiyuan road 36,Chunkou,Liuyang, Hunan,China.

info@steelwireropes.cn

Phone : +86-15573139663

Get help choosing the right wire rope — fast, safe, certified.

WhatsApp us

Fill out a quick form to get a personalized quote tailored to your specific needs.

Note: Your email information will be kept strictly confidential.