1. Introduction

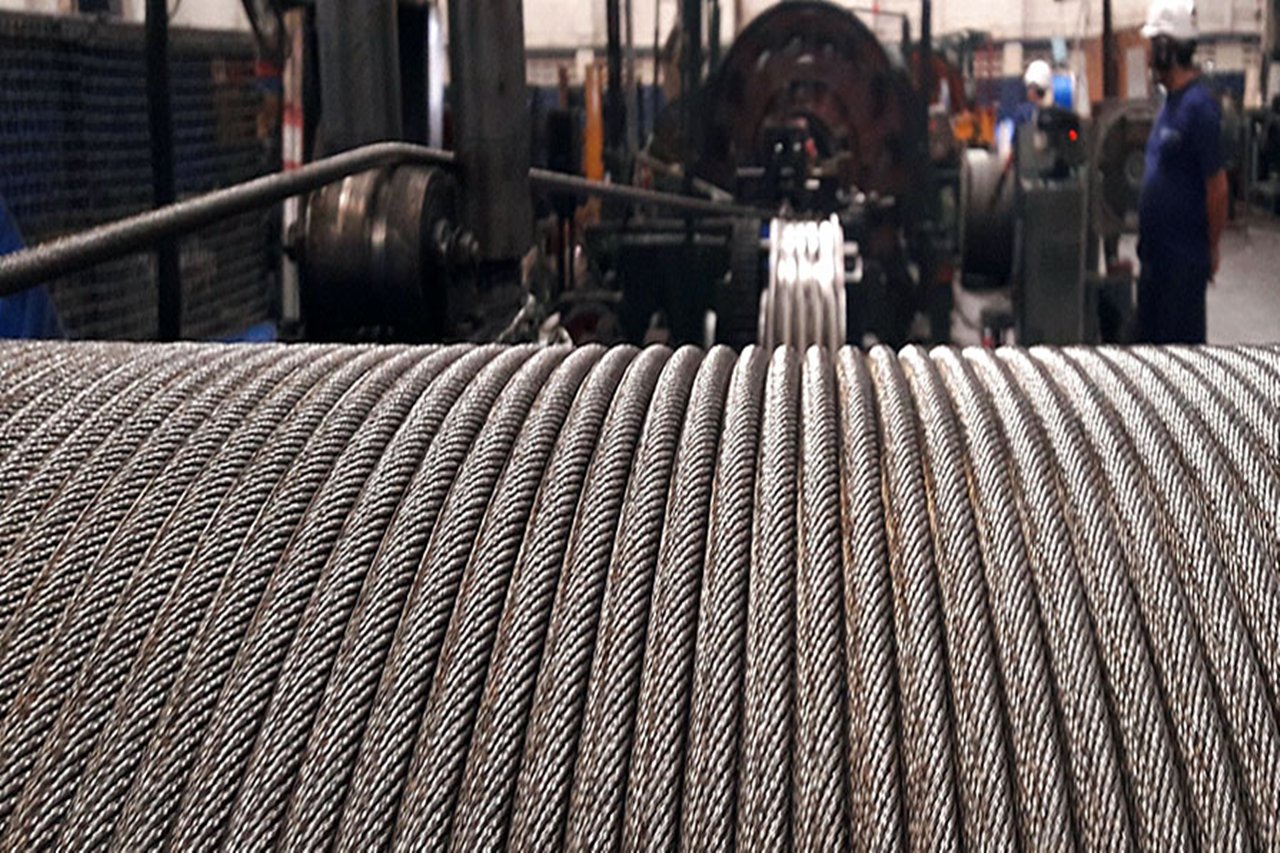

In lifting and hoisting operations, one of the biggest challenges lies in maintaining stability and safety when handling heavy loads. Traditional wire ropes, while strong and versatile, tend to rotate under load due to torque and tension imbalance. This rotation can cause the hook or the lifted object to spin uncontrollably, creating safety risks and reducing operational efficiency.

Rotation-Resistant Ropes (also known as non-rotating or anti-twist wire ropes) are designed to solve this problem. By using special multi-layer strand constructions, these ropes minimize or completely counteract rotational forces, ensuring that loads remain stable even at great lifting heights.

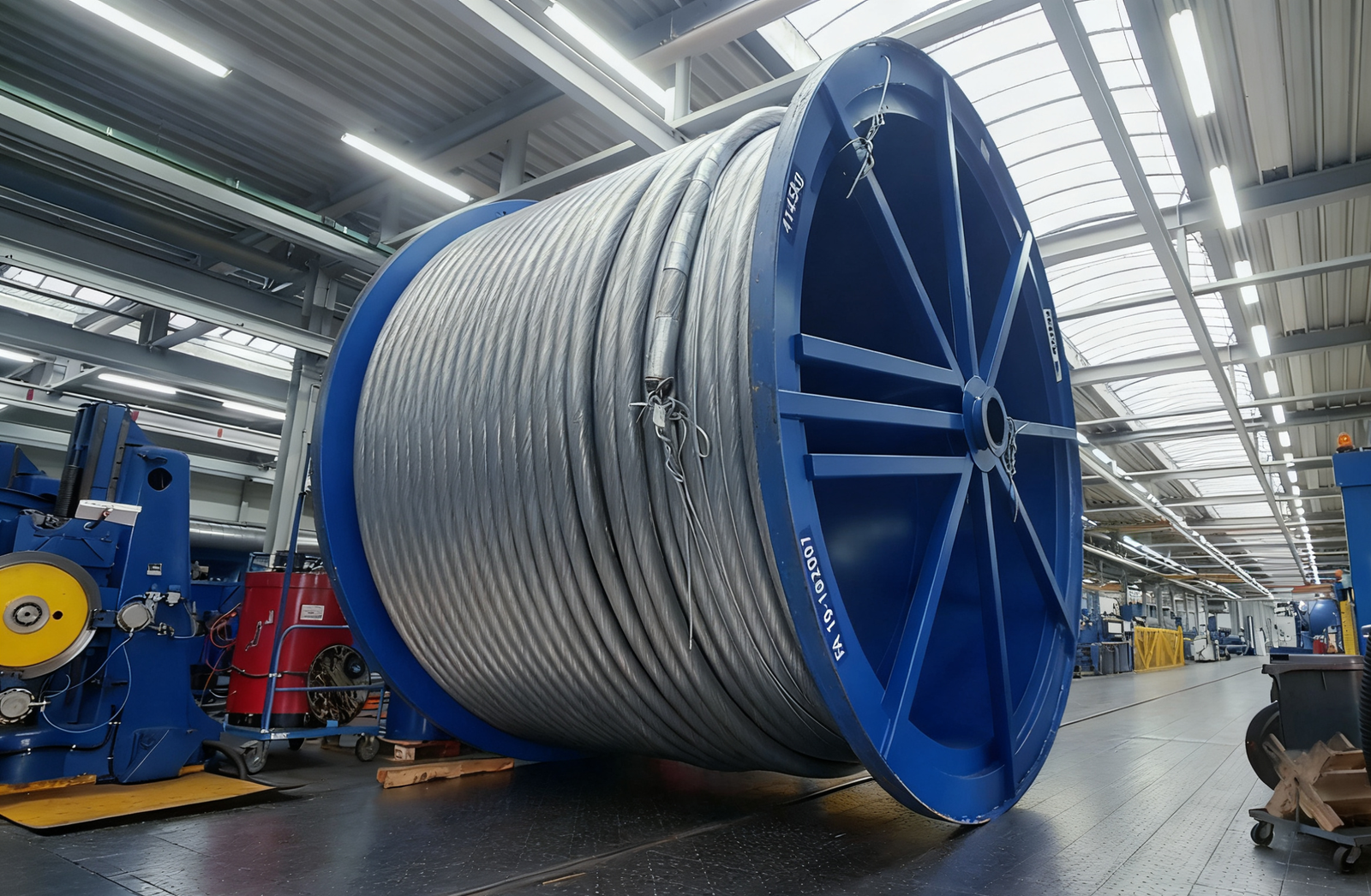

They are widely used in tower cranes, offshore cranes, ship cranes, port equipment, mobile cranes, high-rise construction hoists, and mining hoists—anywhere that precise lifting and safety are top priorities.

2. Working Principle

The core principle of rotation-resistant ropes is torque balance.

- Opposite strand directions: Inner strands and outer strands are laid in opposite directions. The torque generated by the inner layer is counteracted by the torque of the outer layer.

- Multi-layer design: Unlike standard ropes, rotation-resistant ropes typically have two or three layers of strands. The rope lay angle is carefully engineered to achieve equilibrium.

- Load distribution: When under tension, each layer of strands helps neutralize the twisting force of the others, preventing the rope as a whole from rotating.

A common example is the 35WXK7 rope, in which alternating layers of strands ensure excellent resistance to rotation even at high lifting heights.

3. Common Constructions

Rotation-resistant ropes come in several constructions, each optimized for different lifting applications:

3.1 18×7 (Two-Layer Construction)

- Made of 18 strands, each containing 7 wires.

- Considered a traditional rotation-resistant rope.

- Provides moderate resistance to rotation.

- Best suited for medium-duty lifting with limited hoisting heights.

- Cost-effective, though less stable than advanced three-layer constructions.

3.2 35WXK7 (Three-Layer Construction)

- Consists of 35 strands with compacted outer wires.

- Provides superior rotation resistance compared to 18×7.

- High breaking force and long service life.

- Commonly used in tower cranes, mobile cranes, and construction hoists.

3.3 34×7 or 37×7 (Three-Layer Construction)

- Designed for heavy-duty lifting applications.

- Excellent stability with minimal rotation angle.

- Used in offshore cranes, ship cranes, and high-rise building construction where safety is critical.

3.4 Compacted Ropes

- Manufactured with compaction technology that reduces rope diameter while increasing strength.

- Offers improved wear resistance, better spooling on multi-layer drums, and longer fatigue life.

- Particularly suitable for harsh environments and continuous lifting operations.

4. Key Advantages

Rotation-resistant ropes provide several distinct benefits compared with ordinary wire ropes:

- Outstanding rotation resistance

- Maintains load stability, even at extreme lifting heights.

- Reduces hook spinning and swinging.

- Higher safety

- Minimizes the risk of accidents caused by uncontrolled rotation.

- Essential for precise operations such as offshore lifts and urban tower cranes.

- Enhanced strength and durability

- Multi-layer strand design and compacted wires give higher breaking force.

- Resistant to crushing and wear in multi-layer spooling.

- Compatibility with multi-layer drums

- Performs well on winches and hoisting systems that require multiple rope layers.

- Reduces the likelihood of rope distortion and bird-caging.

- Longer service life

- Often galvanized or plastic-coated for additional corrosion resistance.

- Lower fatigue damage due to balanced torque and reduced internal friction.

5. Applications

Rotation-resistant ropes are indispensable in industries where safety and precision are paramount.

- Construction: Tower cranes, construction hoists, high-rise building lifts.

- Ports and logistics: Container cranes, floating cranes, ship loaders.

- Marine and offshore: Ship cranes, offshore platforms, subsea lifting.

- Mining and energy: Mine hoists, drilling rigs, material handling systems.

- Special projects: Bridge construction, wind turbine installation, heavy equipment assembly.

In each of these environments, using non-rotating ropes ensures greater efficiency and minimizes the risks associated with heavy lifting.

6. International Standards and Certification

High-quality rotation-resistant ropes must comply with international standards and may also carry certifications from classification societies.

Key Standards

- EN 12385 – European standard for steel wire ropes.

- ISO 2408 – International wire rope standard.

Common Certifications

- ABS – American Bureau of Shipping.

- DNV – Det Norske Veritas (Norway).

- BV – Bureau Veritas (France).

- LR – Lloyd’s Register (UK).

- RMRS – Russian Maritime Register of Shipping.

- CE – European Conformity mark.

- ISO 9001 – Quality management system certification.

These approvals ensure compliance with safety and performance requirements, giving buyers confidence in reliability and global acceptance.

7. Usage and Maintenance Guidelines

To maximize performance and service life, rotation-resistant ropes must be used and maintained correctly.

- Proper rope selection

- Choose the correct rope construction based on crane type, lifting height, and environment.

- Correct installation

- Avoid kinks, improper tension, or forced twisting.

- Always install ropes under slight tension to prevent slack-induced damage.

- Lubrication

- Apply specialized rope lubricants to reduce internal friction and prevent corrosion.

- Re-lubrication should be carried out at regular intervals.

- Inspection and monitoring

- Check for broken wires, wear, corrosion, and diameter reduction.

- Replace ropes that reach discard criteria according to standards.

- Avoid overloading

- Never exceed the rated load capacity.

- Prevent shock loading, which shortens rope lifespan.

8. Discard Criteria

Like all wire ropes, rotation-resistant ropes have specific discard standards:

- Excessive broken wires in a lay length.

- Outer wire wear exceeding 1/3 of the original diameter.

- Rope elongation or diameter reduction beyond allowable limits.

- Severe corrosion or bird-caging.

- Visible core protrusion or rope distortion.

Regular inspection ensures timely replacement, maintaining safety and minimizing downtime.

9. Future Trends

The development of rotation-resistant ropes is closely tied to advancements in material science and engineering. Future improvements will focus on:

- High-strength steel wires

- Using ultra-high tensile wires to increase breaking force.

- Advanced coatings

- Zinc-aluminum coatings, polymer sheaths, or plastic infill to improve corrosion resistance.

- Smart monitoring

- Embedding sensors into ropes to measure tension, fatigue, and wear in real time.

- Optimized rope designs

- Enhanced torque balance for even greater resistance.

- Longer service intervals and improved fatigue life.

These innovations will ensure safer, more efficient lifting solutions in increasingly demanding applications.

10. Conclusion

Rotation-resistant ropes are essential components in modern lifting technology. Their specialized multi-layer strand construction balances torque forces, providing unmatched stability and safety for heavy loads at great heights.

Compared to conventional ropes, they deliver:

- Superior rotation resistance

- Increased safety and reliability

- Greater breaking strength

- Compatibility with multi-layer spooling

- Longer working life

They are indispensable in construction, marine, offshore, mining, and port operations. With international certifications such as ABS, DNV, BV, LR, and ISO9001, they meet the highest global standards for safety and performance.

As industries demand more precise and efficient lifting solutions, rotation-resistant ropes will continue to evolve, offering stronger, smarter, and more durable options for the future.