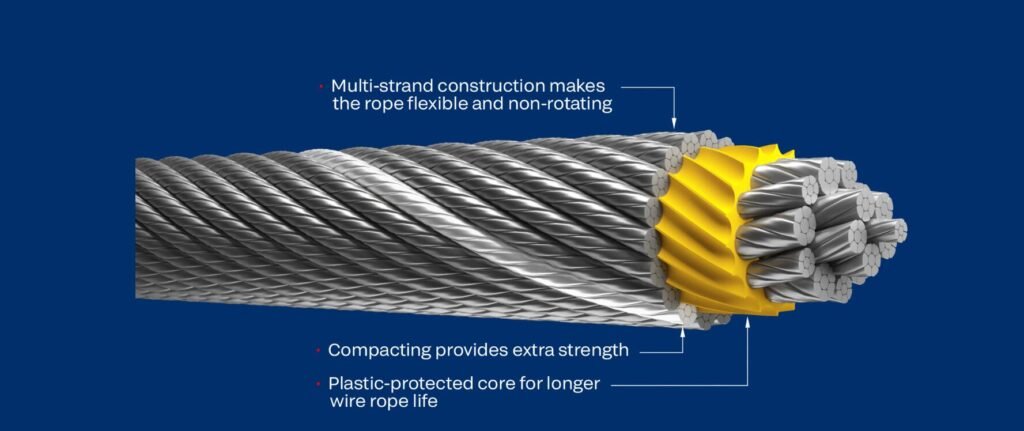

Plastic Impregnation (PI) is a manufacturing process in which a polymer material is injected between the inner and outer strands of a steel wire rope.

This technique significantly enhances the rope’s performance by reducing internal friction, improving bending fatigue resistance, and increasing core stability.

The impregnation is carried out during production through a precision extrusion process, ensuring uniform coverage and thorough filling between strands for maximum protection and durability.

Plastic Impregnated Wire Rope (PIWR) is a high-performance, advanced type of wire rope that integrates conventional steel rope construction with engineered polymeric technology. Designed to enhance fatigue resistance, corrosion protection, and internal lubrication retention, PIWR has become a preferred solution in demanding environments such as offshore drilling, marine lifting, port cranes, mining, and construction hoisting systems.

By injecting or coating the rope’s core and/or inter-strand voids with thermoplastic materials—often polyethylene (PE), polypropylene (PP), or other engineered resins—PIWR delivers outstanding durability, longer service life, and safer operation. This innovation addresses many of the critical weaknesses of traditional wire rope designs, especially in heavy-duty cyclic loading and corrosion-prone environments.

In industrial applications, standard wire ropes face several challenges:

Corrosion due to seawater or chemicals

Internal wear due to repeated bending and contact between wires and strands

Inconsistent lubrication over the rope’s service life

Fatigue failure in multi-layer winding or high-speed operations

Plastic impregnation is an effective solution to mitigate these issues. The polymer layer acts as a barrier, lubricator, and cushion, offering improved performance and reliability.

The plastic layer isolates internal steel wires and the core from external moisture, salt, or aggressive chemicals, drastically reducing corrosion risk. In marine or offshore applications, this feature alone can double the service life of ropes.

When wire ropes bend around sheaves and drums, the relative movement between wires causes wear. Plastic impregnation fills the internal voids between wires and strands, eliminating friction points and reducing fretting fatigue.

The impregnation process typically involves incorporating plastic mixed with lubricants, ensuring permanent lubrication within the core. This prevents lubrication loss over time and maintains smooth wire interaction.

By absorbing and distributing stress across the cross-section, the plastic support layer improves the rope’s ability to withstand repeated load cycles and dynamic bending. This is particularly important in high-speed cranes and continuous lifting.

Plastic-impregnated ropes do not leak oil or grease, keeping machinery cleaner and safer. They also require less frequent relubrication, reducing downtime and maintenance labor.

PIWRs can be designed in multiple forms, depending on the application. The plastic can be applied in different ways:

In many PIWRs, the fiber or steel core is fully coated with plastic to isolate it from the outer strands. This protects the core from moisture ingress and metal-to-metal contact.

The gaps between individual strands are filled with plastic during manufacturing, forming a barrier that prevents internal movement and corrosion. This is commonly used in compacted, rotation-resistant ropes.

Some ropes are completely jacketed in a plastic sheath, offering full protection for subsea and static mooring use. These ropes may also have pressure-equalizing features to prevent water ingress.

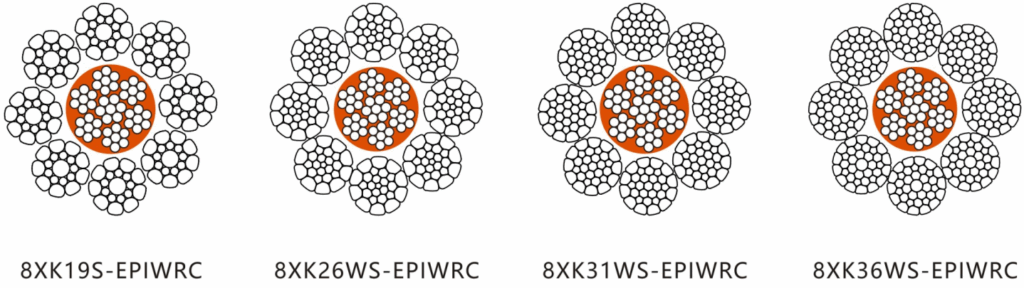

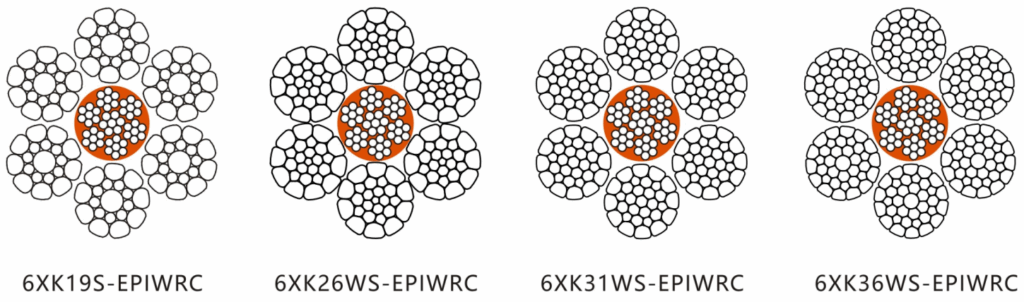

Here are some standard constructions that often feature plastic impregnation:

| Rope Construction | Common Uses | Impregnation Type |

|---|---|---|

| 6×K36WS+IWRC-PIWR | Crane hoist rope, overhead lifting | Core and inter-strand impregnation |

| 8×K26WS-EPIWRC | Rotary drilling rigs, luffing ropes | Plastic-coated core + inter-strand |

| 35×7 (non-rotating) PIWR | Tower cranes, offshore cranes | Fully impregnated + plastic core |

| 19×7 or 19×19 PIWR | Port crane main hoist ropes | Plastic injected core & interstices |

These constructions are often compacted and preformed, further improving strength and fatigue performance.

The choice of polymer greatly affects the rope’s performance. Common materials include:

Polyethylene (PE) – Economical, water-resistant, good flexibility

Polypropylene (PP) – Good chemical resistance, UV resistant

Polyamide (Nylon) – High mechanical strength, but absorbs moisture

PU (Polyurethane) – Abrasion-resistant, suitable for dynamic loads

Custom polymer blends – Tailored for extreme temperatures or special environments

Each material is selected based on the working environment, temperature range, load type, and contact conditions.

The production of PIWR includes additional steps compared to conventional wire ropes:

Strand Compaction (if required)

Pre-lubrication of steel wires

Plastic injection or extrusion into the core or between strands

Rope closing under tension

Final coating or plastic sheathing (if applicable)

Quality inspection – Magnetic, visual, and destructive testing

Precise control over temperature, pressure, and polymer distribution is critical to achieving uniform impregnation.

While specifications vary by rope type, some common technical parameters of PIWR include:

| Parameter | Typical Range |

|---|---|

| Rope Diameter | 6mm to 90mm+ |

| Breaking Force | 1.5x to 2x that of traditional ropes |

| Temperature Range | -40°C to +70°C (depending on plastic) |

| Corrosion Resistance | Excellent (especially with galvanized wires) |

| Minimum Bending Radius | 15x to 20x rope diameter |

| Safety Factor | 5:1 to 7:1 standard for cranes |

Plastic-impregnated ropes are used in harsh environments where safety, longevity, and performance are paramount.

Ship cranes, winches, and mooring lines

Subsea lifting where water ingress must be minimized

FPSOs and drilling rigs requiring rotation-resistant ropes

Tower crane hoist and trolley ropes

Mobile crane boom hoist systems

Multi-layer winding drums

Draglines, skip hoists

Tunneling equipment (TBMs)

Heavy-duty continuous haulage systems

Top drive and deadline ropes

Derrick hoisting systems

Blowout preventer (BOP) lifters

| Feature | Traditional Rope | Plastic Impregnated Rope (PIWR) |

|---|---|---|

| Internal lubrication | Wears off, needs reapplication | Permanently embedded during manufacturing |

| Corrosion resistance | Moderate (galvanized only) | Excellent (barrier protection) |

| Fatigue resistance | Lower | Higher due to reduced internal wear |

| Cleanliness and oil leakage | High | Minimal leakage |

| Maintenance frequency | Higher | Lower |

| Initial cost | Lower | Higher |

| Life-cycle cost | Higher | Lower due to longer lifespan |

Although PIWR reduces the need for frequent maintenance, periodic inspection remains necessary for safety and compliance.

Monitor outer wire wear, especially near fittings

Check for broken wires and corrosion pitting

Examine plastic layer for cracks or peeling

Use magnetic rope testing (MRT) for internal defects

Re-lubrication may not be necessary unless the rope is subjected to extreme washing or mechanical wear.

PIWR ropes are typically produced in compliance with:

ISO 4309: Wire Rope Inspection and Discard Criteria

EN 12385: Steel Wire Ropes for Lifting Applications

API 9A / API RP 54: Drilling and Hoisting Equipment

ABS, DNV, Lloyd’s Register: For marine applications

Third-party testing upon customer request

Reputable manufacturers will provide mill test certificates, quality control reports, and breaking force test data.

At Aulone, we offer fully customizable PIWR solutions based on your project needs:

Diameter and construction customization

Galvanized or bright finish

Plastic type and color (PE, PU, etc.)

Lubrication type: light, medium, or heavy

Independent Wire Rope Core (IWRC) or fiber core options

Pre-tensioning or preforming available

We support third-party inspection, OEM branding, and low MOQ for custom orders.

Plastic Impregnated Wire Rope represents a significant advancement in lifting and hoisting technology. Its superior corrosion resistance, extended fatigue life, and low maintenance make it an indispensable choice for industries that demand durability, safety, and reliability. Whether you’re working on offshore platforms, heavy construction cranes, or mining operations, switching to PIWR can improve operational efficiency and reduce downtime.

If you’re looking for a dependable PIWR supplier, ensure that they offer rigorous quality control, full certifications, and the ability to customize ropes to your application.

At Aulone, we manufacture and export high-performance PIWR ropes tailored to your lifting, drilling, or construction needs. For technical datasheets, samples, or custom quotes, feel free to contact us directly.

Kaiyuan road 36,Chunkou,Liuyang, Hunan,China.

info@steelwireropes.cn

info@wireropes.net

Phone : +86-15573139663

WhatsApp : ++86-15573139663

Accumsan nullam enim curae sapien mattis fringilla

WhatsApp us

Fill out a quick form to get a personalized quote tailored to your specific needs.

Note: Your email information will be kept strictly confidential.