Plastic Impregnated Wire Rope, often abbreviated as PI Wire Rope, is an advanced type of wire rope designed to offer superior performance in harsh working environments. By combining high-strength steel wires with plastic impregnation, this rope achieves excellent resistance to corrosion, wear, and fatigue while maintaining high flexibility and load-bearing capacity.

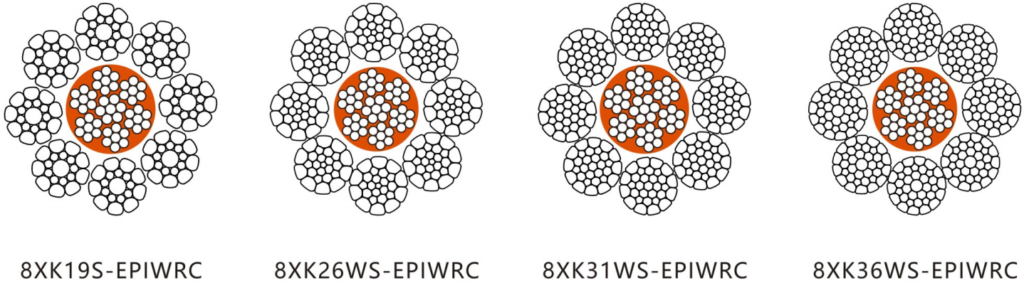

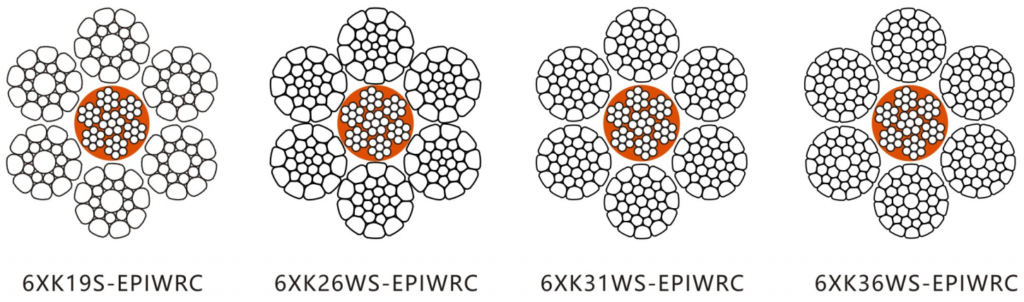

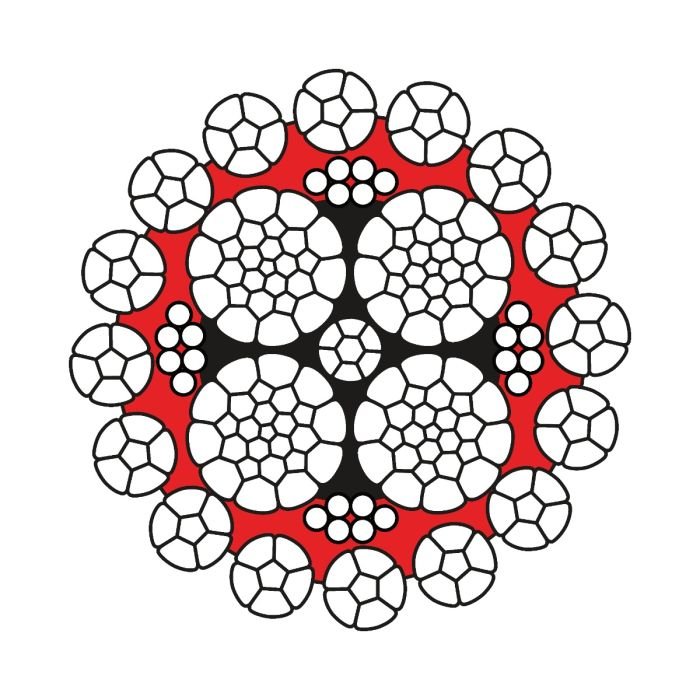

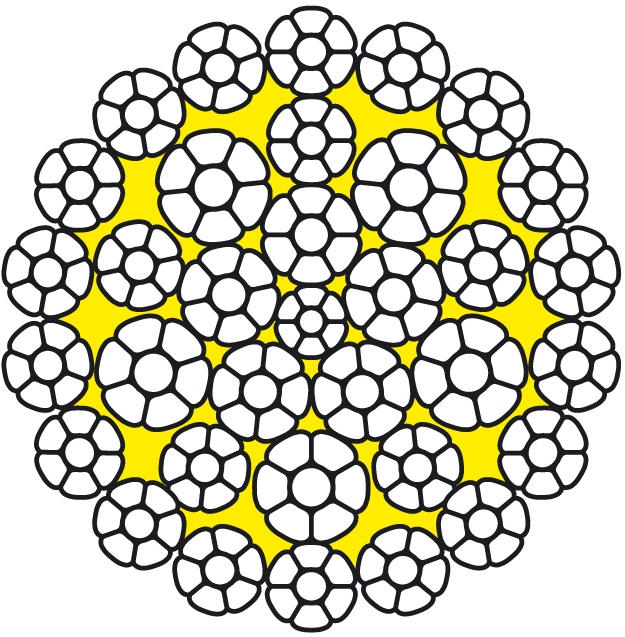

Plastic Impregnated Wire Rope is constructed by filling the spaces between the individual wires in the strands with a specialized plastic compound. The rope generally consists of:

Core: Usually made from fiber (e.g., polypropylene or natural fiber) or steel wire to provide additional strength and shape retention.

Strands: Composed of high-quality carbon or alloy steel wires, twisted together to form a round or shaped cross-section.

Plastic Impregnation: A thermoplastic or polymer material injected under pressure, filling the gaps between wires and strands to prevent internal corrosion and reduce friction.

This structure allows the rope to maintain its mechanical properties over longer service life compared to conventional wire ropes.

Plastic Impregnated Wire Rope provides multiple performance benefits:

Corrosion Resistance: The plastic layer protects inner wires from water, chemicals, and other corrosive agents, making it ideal for marine, offshore, and chemical industries.

Reduced Internal Friction: The impregnation minimizes wire-on-wire friction, reducing wear and extending fatigue life.

Enhanced Lubrication: The plastic acts as a permanent lubricant, ensuring smooth operation without the need for frequent maintenance.

Improved Spooling: Excellent dimensional stability ensures easy winding on drums, even under multilayer spooling conditions.

High Strength and Safety: Maintains the tensile strength of the steel wires while reducing the risk of wire breakage due to fatigue.

Low Stretch: PI wire ropes generally exhibit minimal elongation under load, enhancing operational precision in lifting and hoisting applications.

Plastic Impregnated Wire Rope is widely used in industries where environmental protection and long service life are critical:

Marine and Offshore Operations: Ideal for mooring, anchor handling, and lifting applications exposed to seawater.

Mining and Construction: Suitable for hoists, cranes, draglines, and shovels, where high fatigue resistance is required.

Industrial Lifting: Perfect for elevators, cableways, and heavy-duty material handling.

Chemical Plants: Resistant to corrosive chemicals and moisture, ensuring safety in aggressive environments.

PI Wire Ropes are manufactured according to international standards to guarantee quality and safety:

EN 12385 (Europe): Covers dimensions, construction, breaking force, and testing of steel wire ropes, including plastic-impregnated types.

ISO 2408: Specifies the requirements for steel wire ropes used in general lifting and hoisting applications.

Customer-Specific Standards: Can be customized to meet API, ABS, DNV, or other industry requirements.

Although PI Wire Rope is low-maintenance, regular inspections are recommended to maximize service life:

Check for external damage, such as cuts, abrasions, or unusual deformation.

Inspect for wire breakage or strand distortion, particularly in high-stress areas.

Ensure that drums and sheaves are compatible and that spooling does not generate excessive wear.

Manufacturers can provide PI Wire Ropes tailored to specific operational needs:

Diameter and Length: From small hoisting ropes to large offshore mooring cables.

Core Type: Fiber or steel cores depending on flexibility and load requirements.

Plastic Type: Thermoplastic, polymer, or specialty compounds for chemical or temperature resistance.

Certifications: Support for third-party testing, including load testing and material certification.

Conclusion:

Plastic Impregnated Wire Rope is an ideal choice for industries demanding high-performance, durable, and corrosion-resistant ropes. Its combination of steel strength and plastic protection ensures extended service life, reduced maintenance, and enhanced safety in challenging environments.

Kaiyuan road 36,Chunkou,Liuyang, Hunan,China.

info@steelwireropes.cn

admin@steelwireropes.cn

Phone : +86 15573139663

WhatsApp : +86 15573139663

Expert guidance on wire rope specifications and applications

WhatsApp us

Free samples, product catalog, and expert consultation available.