Plastic Coated Wire Rope is a specialized wire rope designed to combine the high strength and durability of steel with the protective benefits of a plastic coating. In heavy-duty mining applications, such as draglines, shovels, and underground coal mining, these ropes are particularly valued for their resistance to abrasion, corrosion, and environmental hazards, ensuring safe and long-lasting operation.

Plastic Coated Wire Rope for Mining, Dragline, and Shovel Applications

Plastic Coated Wire Rope is a specialized wire rope designed to combine the high strength and durability of steel with the protective benefits of a plastic coating. In heavy-duty mining applications, such as draglines, shovels, and underground coal mining, these ropes are particularly valued for their resistance to abrasion, corrosion, and environmental hazards, ensuring safe and long-lasting operation.

Plastic Coated Wire Rope for Mining, Dragline, and Shovel Applications

Plastic Coated Wire Rope is a specialized wire rope designed to combine the high strength and durability of steel with the protective benefits of a plastic coating. In heavy-duty mining applications, such as draglines, shovels, and underground coal mining, these ropes are particularly valued for their resistance to abrasion, corrosion, and environmental hazards, ensuring safe and long-lasting operation.

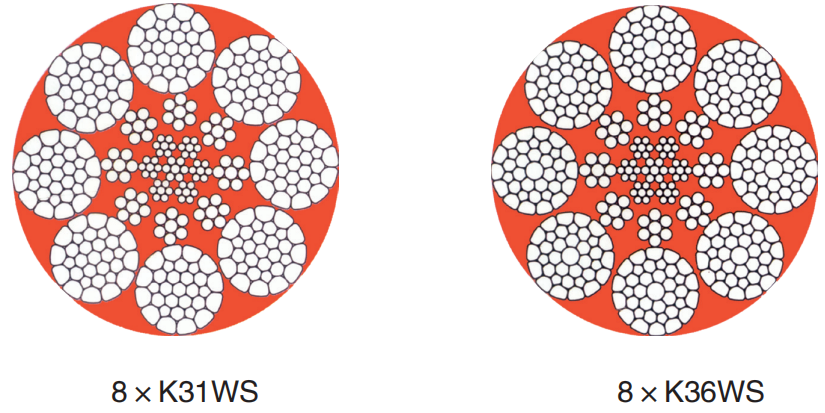

Plastic coated wire ropes for mining are generally made from high-quality steel strands with a durable PVC or PE outer coating. The rope construction is tailored to handle the extreme loads and harsh conditions in mining operations. Typical constructions include:

6×K36WS or 8×K36WS with IWRC – flexible yet strong, suitable for draglines and shovels.

Compacted or shaped strands – enhance wear resistance and improve spooling performance.

Core Options:

IWRC (Independent Wire Rope Core): Provides extra strength and better crushing resistance under heavy loads.

The plastic coating is applied over the finished rope to protect the steel from abrasion, dirt ingress, and corrosion while improving safety and handling.

Plastic coated wire ropes for mining and heavy equipment offer multiple advantages:

Corrosion and Abrasion Resistance: The coating prevents steel strands from rusting and reduces wear caused by continuous contact with pulleys, drums, and guides.

Enhanced Safety: Protects operators from wire splinters and injuries.

Reduced Friction and Longer Life: Smooth coating lowers friction in sheaves and drums, reducing rope fatigue and extending operational life.

Durability in Harsh Environments: Resistant to dust, moisture, chemicals, and extreme temperatures commonly found in mines.

Visual Inspection: Coating color helps operators quickly identify rope wear or damage.

Low Maintenance: Plastic coating reduces the need for frequent lubrication and rope cleaning.

Plastic coated wire ropes are widely used in coal mines, dragline operations, and shovels, where high load capacities and long service life are critical:

Dragline Wire Rope:

Used for the main hoist and drag ropes.

Handles very high tensile loads and cyclic fatigue.

Plastic coating reduces abrasion on the massive sheaves and buckets.

Shovel Wire Rope:

Supports lifting and digging operations.

Coating improves resistance to dirt, coal dust, and abrasive materials.

Non-rotating versions prevent bucket rotation and improve operational safety.

Mine Hoists and Auxiliary Systems:

Used for coal extraction, material handling, and safety lines.

Reduces downtime by providing longer rope service life and easier handling.

PVC (Polyvinyl Chloride): Flexible, durable, UV-resistant, ideal for outdoor mining equipment.

PE (Polyethylene): Excellent chemical resistance, high impact strength, suitable for underground or wet mining conditions.

Coating Thickness: Typically ranges from 1.5 mm to 3 mm depending on rope diameter and application requirements.

Plastic coated wire ropes for mining generally comply with international standards such as EN 12385, ISO 2408, and mining-specific specifications.

Quality Features Include:

High breaking load to meet dragline and shovel requirements.

Plastic coating uniformity and adhesion to prevent peeling.

Lubrication of the inner rope to reduce internal wear.

Salt and dust resistance testing for extreme conditions.

Avoid sharp bends or crushing on sheaves.

Maintain proper sheave diameters according to EN or manufacturer specifications.

Inspect the rope regularly for coating damage, cuts, or frayed wires.

Clean the rope to remove coal dust or abrasive particles, prolonging coating life.

Plastic coated wire ropes are essential in mining, dragline, and shovel operations for ensuring high performance, safety, and long service life. By combining the strength of steel with the protection of a plastic coating, these ropes reduce maintenance, protect equipment, and enhance operational efficiency under the toughest mining conditions.

Kaiyuan road 36,Chunkou,Liuyang, Hunan,China.

info@steelwireropes.cn

admin@steelwireropes.cn

Phone : +86 15573139663

WhatsApp : +86 15573139663

Expert guidance on wire rope specifications and applications

WhatsApp us

Free samples, product catalog, and expert consultation available.