Non-rotating wire ropes, also known as rotation-resistant wire ropes, are engineered to minimize or eliminate rope rotation under load. Unlike standard wire ropes, non-rotating ropes are designed to maintain load stability and ensure safety in lifting, hoisting, and crane operations. Their specialized construction allows them to resist torque, making them indispensable in industries where precision and operational safety are critical.

Rotation-resistant wire ropes are widely used in construction, marine, offshore, mining, and heavy lifting industries. With proper selection of core type, strand construction, and surface treatment, these ropes provide long service life, high strength, and reliable performance even under harsh conditions.

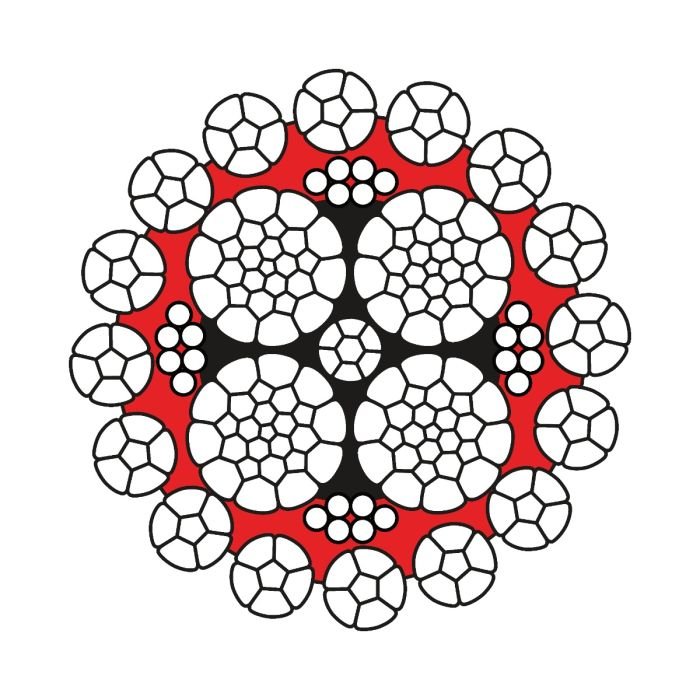

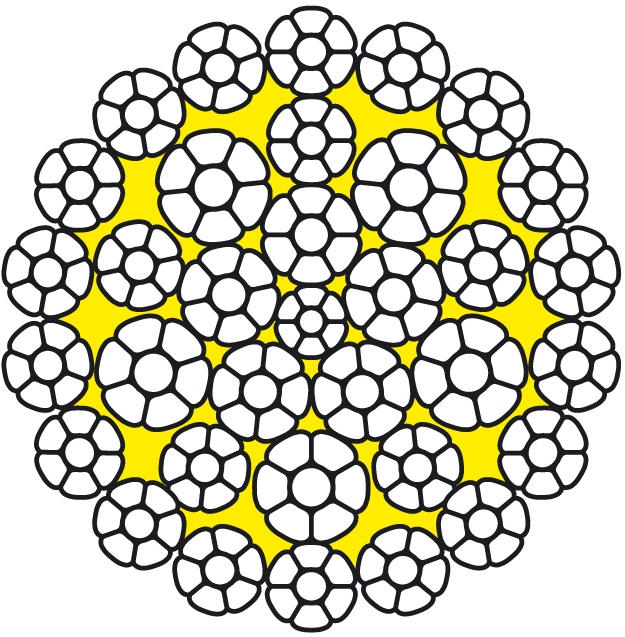

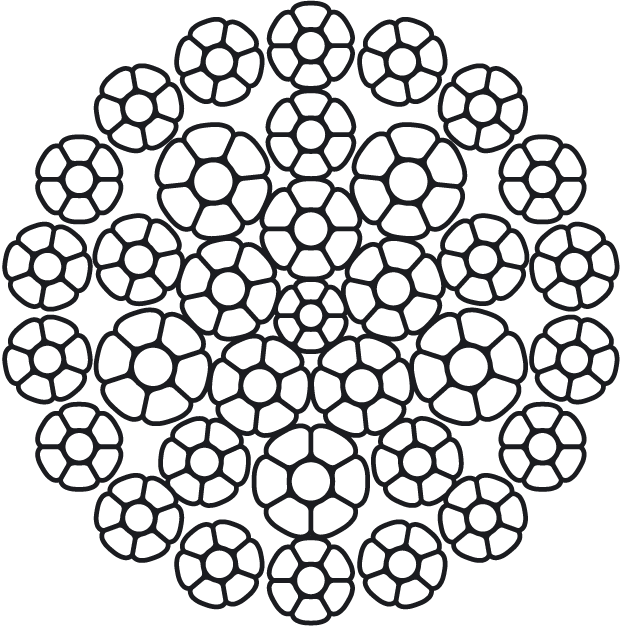

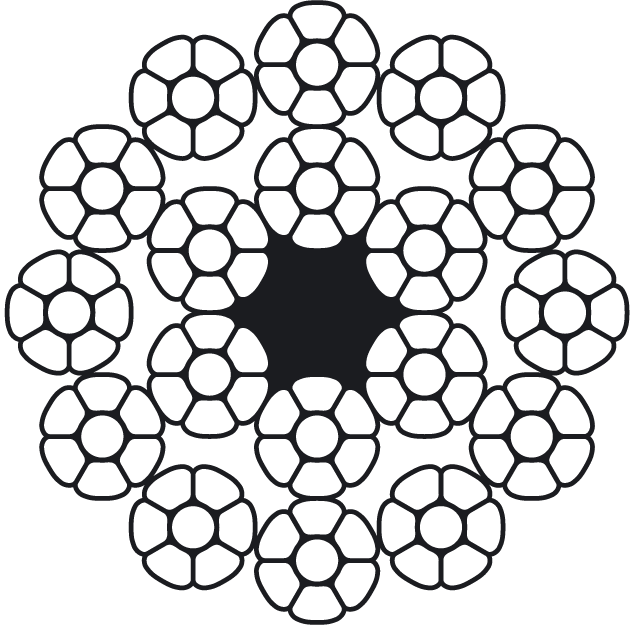

Non-rotating wire ropes are designed using pre-formed strands arranged in balanced and optimized lay patterns. Common constructions include:

| Type | Construction | Characteristics |

|---|---|---|

| 35WXK7 | 35 wires per strand | High-strength, rotation-resistant; suitable for heavy-duty lifting |

| 35WX7 | 35 wires per strand, 7-strand | Optimized for rotation resistance and load stability |

| 15XK7 | 15 wires per strand, 7-strand | Flexible, suitable for medium-duty cranes and hoists |

| 16XK7 | 16 wires per strand, 7-strand | Improved torque resistance and flexibility |

| 19X7 | 19 wires per strand, 7-strand | Excellent rotation resistance and balanced performance |

| 18XK7-WSC | 18 wires per strand, Warrington Seale Construction | High wear resistance, rotation-resistant |

| 18XK7-FC | 18 wires per strand, Fiber Core | Flexible and shock-absorbing, suitable for small sheaves |

| 18XK19S-WSC | 18×19 wires, Warrington Seale Construction | High-strength, rotation-resistant for heavy lifting |

| 18XK19S-FC | 18×19 wires, Fiber Core | Flexible, corrosion-resistant, ideal for wet or marine environments |

Notes:

WSC (Warrington Seale Construction): Provides optimal wear resistance and uniform load distribution.

FC (Fiber Core): Offers enhanced flexibility and internal shock absorption.

Stable rope performance with polymer-coated core

Better corrosion resistance

Longer service life

Excellent rotation resistance

• High flexibility

• High strength

• Reduced friction between outer wires in strands and pulley groove surface

• Rotation resistance

• High strength

• High abrasion resistance

• High fatigue failure resistance

• Expanded contact with bearing surface area

• Less wear of sheaves and capstans

• rotation resistance

• High flexibility

• High strength

• Less wear of wires in the strands contact points

• Less wear of sheaves and capstans

• Rotation resistance

The core of a wire rope plays a vital role in its flexibility, strength, and durability. Non-rotating ropes typically use one of the following core types:

Steel Wire Core (IWRC – Independent Wire Rope Core)

Provides maximum strength and crush resistance.

Ideal for heavy-duty lifting and industrial cranes.

Compatible with galvanization or plastic impregnation.

Fiber Core (FC)

Enhances flexibility and bending performance.

Absorbs internal friction and reduces wear.

Often used in smaller cranes, hoists, and wet environments.

To enhance corrosion resistance, durability, and safety, wire ropes can be treated with galvanization or plastic impregnation.

Process: Steel wires are coated with zinc through hot-dip or electro-galvanization.

Advantages:

Excellent corrosion resistance for outdoor or marine use.

Maintains original strength and rotation-resistant properties.

Commonly used in construction, mining, and port operations.

Example: 35WXK7 galvanized non-rotating rope is widely used in tower cranes or shipboard lifting equipment for outdoor operations.

Process: The rope is impregnated with plastic such as PVC or PE, forming a protective layer.

Advantages:

Superior corrosion resistance, especially in wet or saline environments.

Reduced internal friction, extending service life.

Improved safety: plastic layer prevents steel wires from protruding if broken.

Visual appeal: color coding possible for identification.

Example: 18XK19S-FC plastic-impregnated rope is ideal for offshore lifting operations, maintaining rotation resistance and extending rope life.

Non-rotating wire ropes are manufactured according to international standards, ensuring safety, reliability, and consistency. Key standards include:

EN 12385 Series (Europe)

Specifies general requirements, construction types, testing, and certification.

Defines breaking load, elongation, and inspection criteria.

ISO 2408 / ISO 4344

Specifies dimensions, tolerances, and minimum performance requirements for steel wire ropes.

Application-specific certifications may include third-party testing for corrosion resistance, breaking force, and fatigue resistance.

Rotation Resistance: Prevents load twisting and ensures safe lifting operations.

High Strength & Durability: Optimized strand design and core choice enhance mechanical performance.

Flexibility: Especially with FC core, the rope is easier to handle and bend around sheaves.

Corrosion & Wear Resistance: Galvanization and plastic impregnation extend rope service life.

Safety: Reduced wire protrusion and better load stability minimize operational hazards.

Non-rotating wire ropes are essential wherever load stability and safety are critical. Typical applications include:

Construction Cranes: Tower cranes, mobile cranes, and heavy-duty hoists.

Marine & Offshore Operations: Ship cranes, dockside lifting, and offshore platforms.

Mining & Excavation: Lifting equipment for mining and tunnel construction.

Industrial Hoists: Elevators, heavy machinery lifting, and specialized lifting devices.

When selecting a non-rotating wire rope, consider the following:

Load Capacity: Match rope breaking force to maximum working load with proper safety factor.

Core Type: Fiber cores for flexibility; steel cores for strength and crush resistance.

Coating & Treatment: Galvanized for corrosion protection; plastic-impregnated for wet or offshore environments.

Application Environment: Consider temperature, chemical exposure, and abrasion.

Sheave & Drum Size: Ensure bending radius meets rope specifications to avoid premature wear.

Non-rotating wire ropes are engineered to provide exceptional rotation resistance, high strength, and long service life. By selecting the proper strand construction, core type, and surface treatment, operators can ensure safe, efficient, and durable lifting operations across diverse industries.

Whether using galvanized ropes for outdoor applications or plastic-impregnated ropes for wet environments, non-rotating wire ropes remain a critical component in modern lifting and hoisting systems.

Kaiyuan road 36,Chunkou,Liuyang, Hunan,China.

info@steelwireropes.cn

admin@steelwireropes.cn

Phone : +86 15573139663

WhatsApp : +86 15573139663

Expert guidance on wire rope specifications and applications

WhatsApp us

Free samples, product catalog, and expert consultation available.