Mining operations demand safety, efficiency, and reliability. A rope failure can halt work for days and cost millions. How can dragline ropes make a difference and ensure smooth operations?

Dragline ropes provide high tensile strength, durability, and long service life. Choosing the right rope ensures operational safety and reduces costs.

I remember a mine site where a rope failure caused a week-long downtime. It taught me the importance of selecting ropes not just by price, but by design, performance, and application.

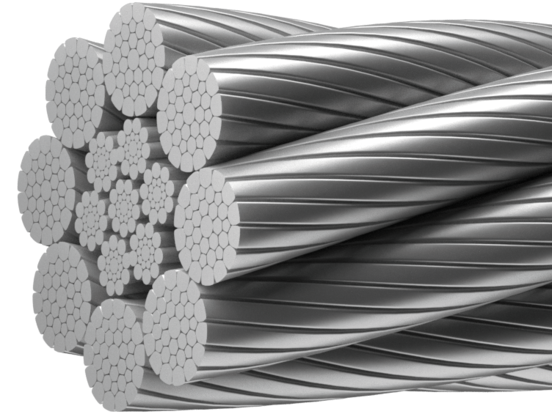

What Makes Dragline Ropes Different from Other Mining Wire Ropes?

Not all wire ropes are built the same. Why do dragline ropes perform better in mining operations?

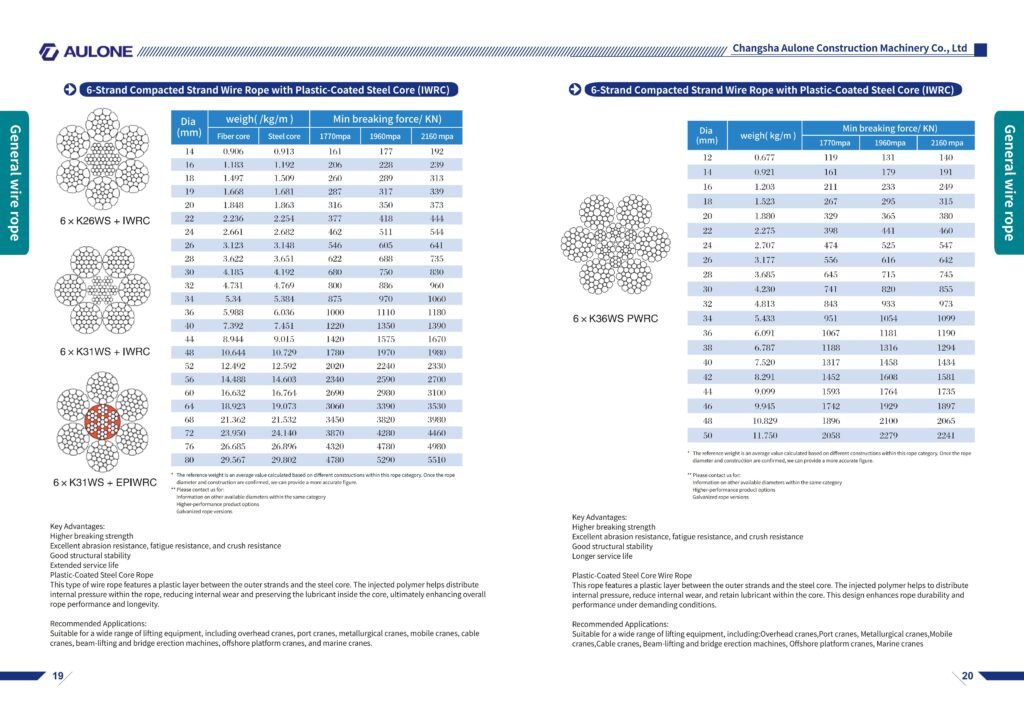

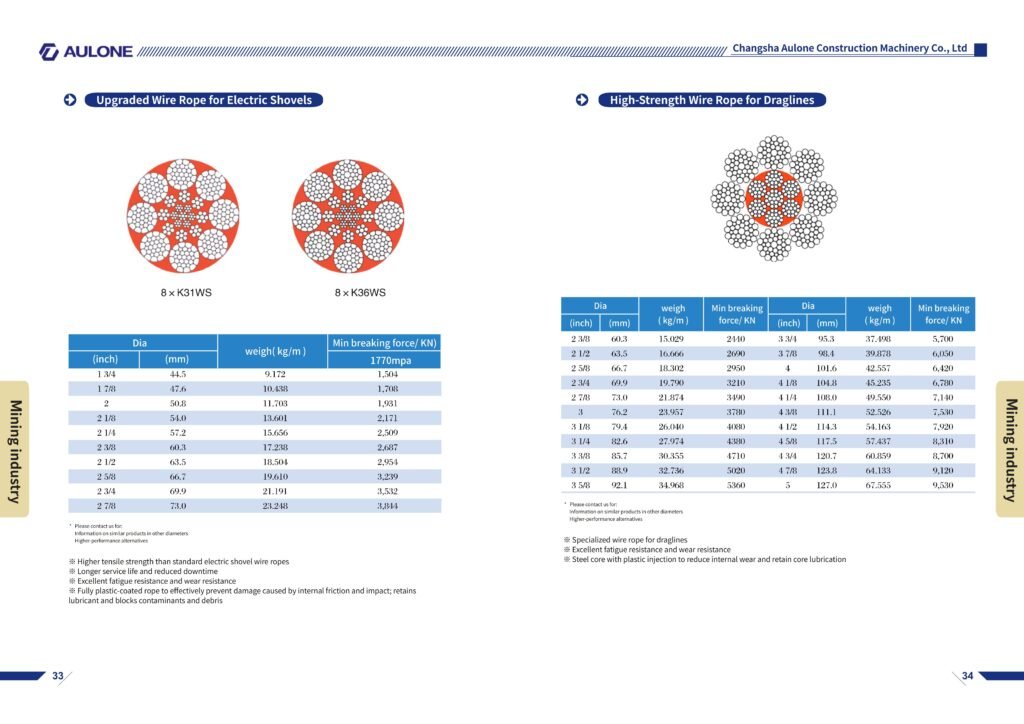

Dragline ropes have specialized constructions that allow them to carry heavy loads over long distances while minimizing wear. Recommended models include EP8XK36WS-IWRC, EP6XK36WS-IWRC, 6XK36WS-IWRC, 8XK26WS-IWRC, 8XK36WS-EPIWRC, and spiral strand wire ropes.

Rope Construction and Performance

| Feature | Benefit | Recommended Model |

|---|---|---|

| Plastic impregnated | Reduce internal wear | EP8XK36WS-IWRC, EP6XK36WS-IWRC |

| Steel core | High tensile strength | 6XK36WS-IWRC, 8XK26WS-IWRC |

| Galvanized wires | Corrosion resistance | 8XK36WS-EPIWRC |

| Spiral strand | Flexible and durable | Spiral strand wire ropes |

Choosing the right construction ensures stability and reduces replacement costs. At one site, switching to 6XK36WS-IWRC cut downtime by nearly 30%.

What Are the Advantages of 6XK36WS-IWRC?

Some ropes are better suited for large draglines. What makes 6XK36WS-IWRC ideal?

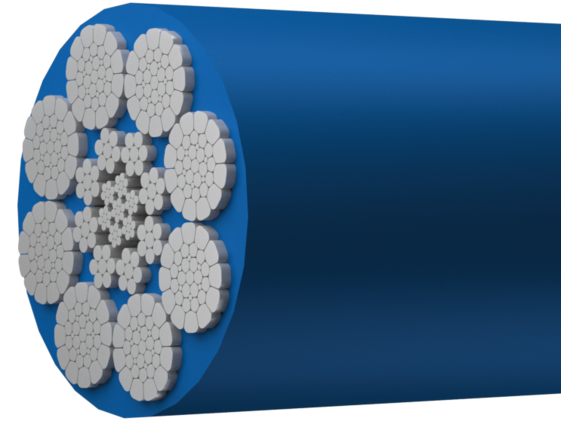

6XK36WS-IWRC is perfect for hoist ropes on large draglines. It features compacted outer strands, excellent wear resistance, increased rope surface area, higher breaking force, reduced stress, and less internal friction.

Key Advantages and Applications

| Advantage | Benefit |

|---|---|

| Compacted outer strands | Improves surface contact and reduces wear |

| Excellent wear resistance | Longer service life under abrasive conditions |

| Increased rope surface area | Distributes load evenly |

| Higher breaking force | Safer operation for large loads |

| Reduced stress levels | Minimizes internal rope damage |

| Less internal friction | Reduces heat and prolongs rope life |

Applications:

- Hoist Rope (Dragline)

- Large-diameter dragline operations

Using 6XK36WS-IWRC on a large hoist improved uptime and reduced rope replacement costs dramatically.

What Are the Advantages of 8XK26WS-IWRC?

Opening Paragraph for H2:

Why is 8XK26WS-IWRC recommended for large-diameter draglines?

8XK26WS-IWRC offers compacted outer strands, excellent wear resistance, high breaking force, and less internal friction. It’s ideal for large draglines handling heavy loads.

Key Advantages

| Advantage | Benefit |

|---|---|

| Compacted outer strands | Improves rope surface durability |

| Excellent wear resistance | Handles abrasive mining environments |

| Increased rope surface area | Ensures even load distribution |

| High breaking force | Maximizes operational safety |

| Reduced stress levels | Minimizes rope fatigue |

| Less internal friction | Prolongs rope life |

Using 8XK26WS-IWRC increased safety and longevity for heavy-duty draglines in a large Australian mine.

What Are the Advantages of EP8XK36WS-IWRC?

How does EP8XK36WS-IWRC perform in smaller draglines?

EP8XK36WS-IWRC is engineered for small draglines with a unique polymer formulation resilient in extreme temperatures. It resists abrasion and bending fatigue and is tested under harsh conditions.

Performance Features

| Feature | Benefit |

|---|---|

| Unique polymer formulation | Resilient in extreme temperatures |

| Abrasion and bending fatigue resistance | Extends rope operational life |

| Tested in extreme conditions | Reliable performance in harsh mining sites |

EP8XK36WS-IWRC reduces maintenance cycles for small draglines, letting operators focus on production.

What Are the Advantages of 8XK36WS-EPIWRC?

Why choose plastic impregnated 8XK36WS-EPIWRC?

It reduces internal wear, improves bending fatigue resistance, and increases rope life under extreme mining conditions.

Key Features

| Feature | Benefit |

|---|---|

| Plastic impregnation | Reduces internal wear |

| High tensile steel core | Handles heavy loads |

| Durable coating | Resists corrosion |

This rope lasted 40% longer than standard galvanized ropes in extreme Southeast Asian mining conditions.

What Are the Advantages of Spiral Strand Wire Ropes?

Why are spiral strand ropes ideal for pendants and mooring lines?

They have good fatigue resistance, are heavily galvanized up to 400gm/m², and pre-stressed at the factory for faster installation and stable performance.

Features and Applications

| Advantage | Benefit |

|---|---|

| Good fatigue resistance | Handles repeated load cycles |

| Heavy galvanization | Long-term corrosion protection |

| Factory pre-stress & assembly | Shorter installation time |

| Pre-stretched | Reduces elongation |

Applications:

- Dragline pendants

- Shovel pendants

- Permanent mooring lines

Spiral strand ropes save installation time and maintenance, ideal for heavy-duty pendant lines.

How Do I Choose the Right Diameter and Length for Dragline Ropes?

Choosing the wrong diameter or length risks rope failure. What should you consider?

Select a diameter for load requirements. Length must fit travel distance and drum capacity. Models like EP8XK36WS-IWRC, 6XK36WS-IWRC, and 8XK26WS-IWRC come in various diameters and lengths for most draglines.

Calculating Specifications

| Parameter | Consideration | Impact | Recommended Models |

|---|---|---|---|

| Diameter | Load and lift height | Prevent snapping | EP8XK36WS-IWRC, 6XK36WS-IWRC |

| Length | Travel distance | Avoid bending | 8XK26WS-IWRC, 8XK36WS-EPIWRC |

| Sheave size | Minimum bending radius | Reduce wear | All recommended ropes |

We always check drum capacity, sheave diameter, and load limits before finalizing dragline rope orders.

Conclusion

Choosing the right dragline rope improves safety, efficiency, and rope longevity. Recommended models include 6XK36WS-IWRC, 8XK26WS-IWRC, EP8XK36WS-IWRC, EP6XK36WS-IWRC, 8XK36WS-EPIWRC, and spiral strand wire ropes. Understanding each model’s advantages ensures optimal performance and cost savings.