Are you struggling with wire rope that twists and spins uncontrollably during operation? It’s a common frustration that can lead to inefficient lifts and even safety concerns.

For demanding applications, Class 19×7 rotation resistant wire rope offers superior stability and reduced torsional tension. Our ropes provide exceptional performance when you need it most.

The challenges of managing unpredictable wire rope behavior can be immense. But what if there was a solution that brought precision and control back to your operations? Let’s explore how.

How Does Class 19×7 Rope Prevent Rotation?

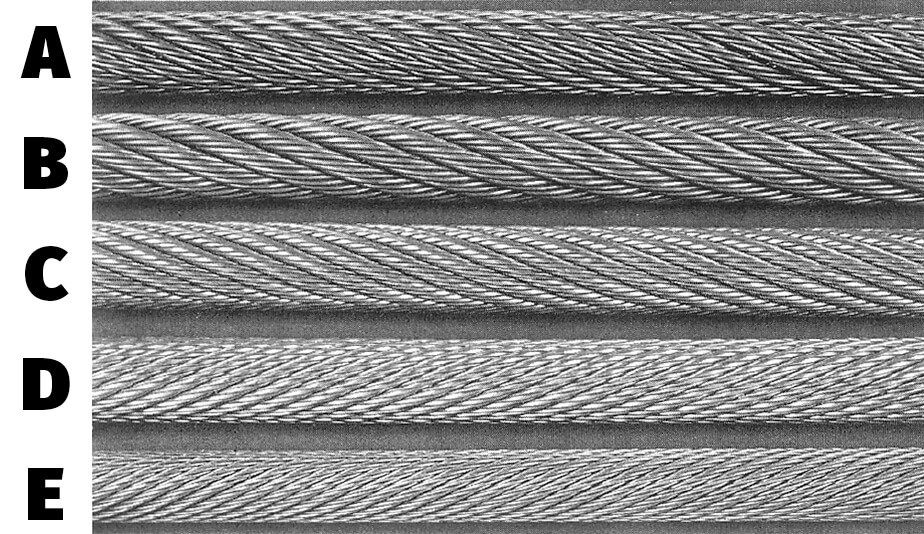

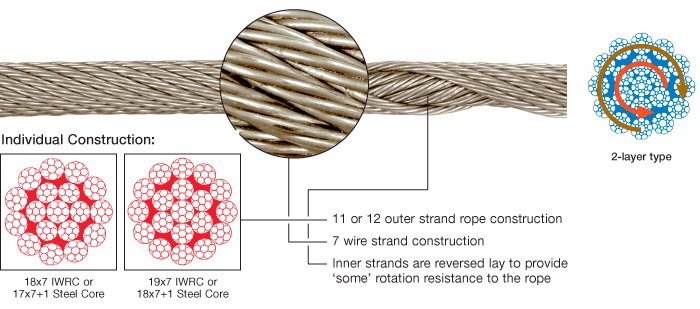

When selecting wire rope, understanding its construction is key to predictable performance. This specific rope type is designed to counteract the inherent torque in lifting, unlike less specialized constructions.

Class 19×7 wire rope achieves its rotation-resistant properties through a unique inner and outer layer configuration. This design minimizes the twisting effect under load, ensuring a stable lift, which is a significant advantage over ropes like the 6×19 class.

The Science Behind Stability

The specific lay of the outer strands in a 19×7 construction is designed to counterbalance the rotational forces. The inner layers are laid in one direction, while the outer layers are laid in the opposite direction. This opposing lay cancels out the torque.

This counteracting lay is why 19×7 rope is often the preferred choice for single-line lifting applications where rotation is a significant concern. Without this feature, a standard rope would spin and unwind, making precise lifting impossible.

What Are the Key Benefits of Using 19×7 Rotation Resistant Wire Rope?

Choosing the right wire rope directly impacts your operational efficiency and safety. Understanding the advantages of 19×7 rope helps in making informed decisions.

The primary benefit of 19×7 rope is its exceptional resistance to rotation. This means more stable lifts, reduced operator fatigue, and better control during operation.

Enhanced Lifting Stability

Imagine lifting a heavy load with a rope that constantly tries to spin. This instability makes it difficult to position the load accurately and can strain equipment.

- Precise Load Placement: The anti-rotational properties allow for much finer control over load positioning, which is critical in many industrial settings.

- Reduced Slinging Time: Less time spent fighting rope twist means quicker setup and execution of lifts.

Increased Durability and Service Life

When a wire rope twists excessively, internal stresses increase. This can lead to premature wear and a shorter service life.

- Lower Internal Stress: By resisting rotation, the 19×7 construction reduces internal friction and stress within the rope. This contributes to a longer lifespan.

- Resistance to Bird-Caging: A common wire rope failure mode where the outer strands separate is less likely with rotationally stable ropes.

Compliance and Certification

Meeting industry standards is non-negotiable for safety and reliability, especially in demanding sectors like mining and crane operations.

- Meeting EN12385-4 Standards: Our ropes are manufactured to meet stringent international standards, ensuring consistent quality and performance.

- Available Certificates: We can provide certifications like BV, CE, RMRS, DNV, and ABS upon request, giving you the assurance you need for your specific project requirements.

When Should You Avoid Using Rotation Resistant Wire Rope?

While 19×7 rotation resistant wire rope offers significant advantages, it’s not always the optimal solution for every lifting scenario. Understanding its limitations is as important as knowing its strengths.

Rotation resistant ropes are typically not designed for applications where the load itself provides the counter-torque, such as in multi-reeved systems or when hoisting a load that is designed to spin naturally.

Understanding the Application Context

The effectiveness of rotation resistant ropes is highly dependent on the specific lifting configuration.

- Multi-Part Reevings: In systems with multiple parts of the rope supporting the load (like a block and tackle), the opposing forces can negate the benefit of rotation resistance. Different rope constructions might be more suitable here.

- Applications Requiring Controlled Spin: Some specialized operations might require the load to rotate. In such cases, a standard rope would be preferred over a rotation-resistant one.

Load Characteristics and Counter-Torque

The nature of the load being lifted plays a crucial role in determining rope suitability.

- Self-Unwinding Loads: If the load itself has a tendency to unwind or has a significant imbalance that creates its own counter-torque, using a rotation-resistant rope might not be beneficial and could even be detrimental.

- Balanced Lifting: For balanced lifting operations where torsional forces are naturally minimized, the added complexity and cost of rotation-resistant rope might not be justified.

Can Customization Enhance the Performance of Your Wire Rope?

Tailoring wire rope to specific operational needs can unlock new levels of efficiency and longevity. Considering customization options can lead to significant improvements in performance.

Customization, such as plastic impregnation and logo application, can further enhance your wire rope’s durability and branding. This offers a more tailored solution for your unique operational demands.

Plastic Impregnation for Added Protection

Plastic impregnation fills the internal voids within the wire rope, offering several advantageous properties.

- Corrosion Resistance: The plastic acts as a barrier, significantly improving resistance to corrosion, especially in harsh or marine environments.

- Reduced Internal Abrasion: It lubricates the internal wires, minimizing friction and wear as the rope flexes, thereby extending its service life.

- Moisture Barrier: Prevents water from penetrating the core of the rope, which is crucial for preventing internal rust and degradation.

Visible Branding with Customizable Logos

For businesses, maintaining brand visibility and professionalism across all operational aspects is important.

- Brand Recognition: Applying your company logo to the wire rope can reinforce brand identity during operations.

- Ease of Identification: Distinctive branding can also make it easier to identify your equipment, which is beneficial for management and maintenance.

- Professional Appearance: It lends a professional touch to your equipment and operations, projecting an image of a well-established and organized company.

Conclusion

Class 19×7 rotation resistant wire rope offers superior stability for demanding lifts.