Are you wrestling with the complex choice of wire rope lay direction for your mining operations? It’s a critical decision that impacts safety and efficiency.

Selecting the right lay direction is crucial for preventing premature rope failure, ensuring maximum lifespan, and maintaining stable hoisting.

Imagine winding your way through a mine, trusting your lifeline. The lay direction is more than just a technical detail; it’s about ensuring every lift is secure.

Understanding Wire Rope Lay: What Does It Mean for Hoisting?

Have you ever looked at a wire rope and noticed the way its strands are twisted? This twist is known as the lay direction, and it’s far more than a cosmetic feature.

The lay direction significantly impacts a wire rope’s performance, influencing its resistance to rotation, its flexibility, and how it handles external forces during hoisting.

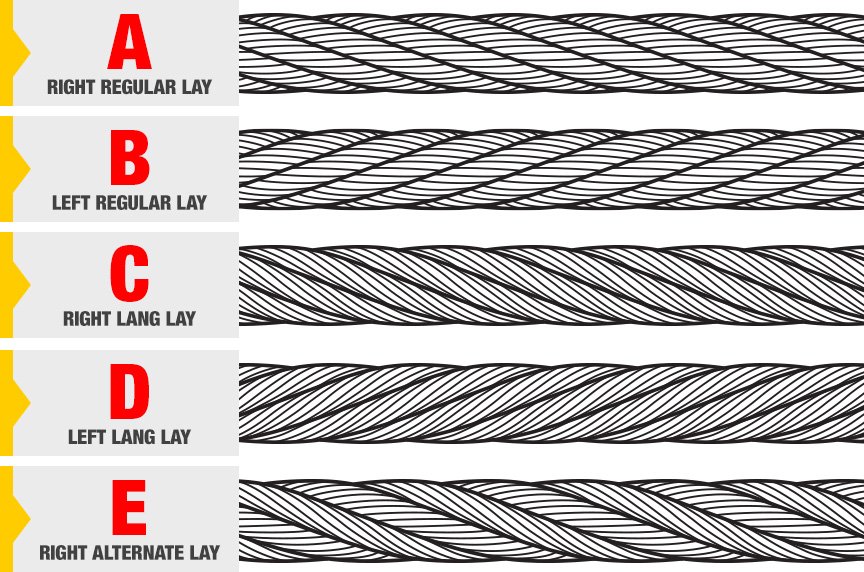

Types of Wire Rope Lay

Let’s break down the common types of lay directions you’ll encounter. This knowledge is fundamental to making an informed decision.

| Lay Type | Description |

|---|---|

| Right Lay | Strands are twisted to the right. |

| Left Lay | Strands are twisted to the left. |

| Lang Lay | Outer wires lie parallel to the rope axis; offers better abrasion resistance. |

| Regular Lay | Outer wires lie at an angle to the rope axis. |

Regular Lay vs. Lang Lay

When considering lay direction, the distinction between Regular Lay and Lang Lay is paramount for mining applications. Each offers distinct advantages based on the operational demands.

Regular lay ropes are the traditional choice for many hoisting applications because of their inherent stability. Their construction inherently resists the spiraling tendency, which is vital for maintaining control in vertical lifts and preventing undue stress on the hoist system.

Benefits of Regular Lay in Hoisting

Regular lay ropes are the traditional choice for many hoisting applications because of their inherent stability.

Their construction inherently resists the spiraling tendency, which is vital for maintaining control in vertical lifts and preventing undue stress on the hoist system.

Resistance to Rotational Forces

In hoisting, especially with heavy loads, torsional forces can cause the rope to spin. Regular lay ropes are designed to combat this.

The opposing lay direction of the strands creates a natural counter-torque, significantly reducing unravelling and maintaining the rope’s integrity under load.

Flexibility and Handling

While prioritizing stability, regular lay ropes also offer a good balance of flexibility.

This makes them easier to handle and reeve through sheaves and drums, simplifying installation and maintenance processes in demanding mine sites.

Advantages of Lang Lay in Mining

Lang lay ropes are often favored in abrasive mining conditions due to their unique construction.

The longer lay length and the parallel lay of the outer strands mean more surface contact, leading to enhanced resistance against abrasion and crushing.

Enhanced Abrasion Resistance

Mining environments are notorious for their abrasive materials, which can quickly degrade conventional ropes.

Lang lay’s construction allows the outer wires to lie flatter, providing a larger contact area that can withstand the scraping and grinding common in mineral extraction.

Superior Fatigue Life

The flexibility and better load distribution in Lang lay ropes can also contribute to a longer operational life.

This means less frequent replacement, leading to cost savings and reduced downtime, critical factors in continuous mining operations.

The Impact of Lay Direction on Rope Performance

It’s not just about which type of lay is better, but how the chosen direction specifically interacts with your hoisting system and operational environment.

The correct lay direction ensures the rope functions efficiently, minimizes wear, and maximizes its service life, directly impacting operational safety and cost.

Preventing Rope Twist and Cage Oscillation

One of the most significant issues in hoisting is rope twist, which can lead to dangerous cage oscillation.

Choosing a lay direction that counteracts the torque generated by the load and the hoist mechanism is fundamental to maintaining a stable and safe hoisting operation.

Load Distribution and Strand Integrity

How the load is distributed across the rope’s core and outer strands is heavily influenced by the lay direction.

The right lay direction ensures even stress distribution, preventing localized stress points that could lead to strand or wire failure.

Right Lay vs. Left Lay: Which Direction is Optimal?

When it comes to hoisting in mines, the choice between a right lay and a left lay rope isn’t arbitrary; it depends on the mechanics of your hoist and the expected operating conditions.

The decision hinges on understanding how torque is applied to the rope and selecting a lay that naturally counteracts this tendency for optimal control.

Factors Influencing Your Choice

Several key operational factors will guide your selection between right and left lay ropes. It’s about balancing the forces at play.

Consider the drum winding direction, the hoist system’s torque characteristics, and the potential for external influences that might induce rotation.

Drum Winding Direction and Torque

The way the rope winds onto the hoist drum is a primary determinant. As the rope winds, it can impart torque.

If your hoist drum operates in a way that tends to twist the rope in one direction, selecting the opposite lay direction will provide a natural counter-balance.

Left Lay Rope for Right Hand Wind

A common scenario is using a left lay rope when the winding on the drum is to the right.

This configuration typically helps to minimize unwanted rotation, keeping the cage stable and the rope running true.

Right Lay Rope for Left Hand Wind

Conversely, a right lay rope is often preferred for left-hand winding drums.

This pairing aims to neutralize the rotational forces, preventing the rope from spinning and promoting smoother operation.

Effects of Load and Gravity

Even without drum interaction, the load itself and gravity can introduce torsional forces.

The inherent properties of the rope’s lay are designed to counteract these forces, ensuring the load hangs straight and remains stable during vertical movement.

The ‘Reversed Lay’ Principle

The concept of “reverse lay” is crucial in explaining why certain lay directions are chosen for specific winding scenarios.

Applying the reverse lay principle means that if the drum winds the rope in a clockwise (right-hand) direction, a left-lay rope is typically used to counteract this.

How It Minimizes Rotation

Understanding this principle is key to preventing operational headaches.

By having the rope’s lay direction oppose the drum’s winding direction, the resulting torque forces in the rope are significantly reduced.

Practical Application in Hoisting Systems

In practice, this means careful consideration of your specific hoist configuration is a must.

Many hoisting systems are designed with the expectation of a specific lay direction to achieve the most stable and predictable performance.

Considerations for Different Mining Applications

The type of mining operation and the specific duties the wire rope performs will heavily influence the optimal lay direction choice.

From deep shaft hoisting to surface operations, each task presents unique challenges that the rope’s lay direction must be able to meet.

Deep Shaft Hoisting Requirements

Deep shafts present the most extreme conditions, requiring the utmost attention to rope stability.

In very deep shafts, the cumulative torque and the sheer weight of the rope itself mandate a lay direction that offers maximum resistance to rotation.

Preventing Cage Rotation and Swinging

The longer the drop, the more time there is for torsional forces to build up and cause problems.

A rope with a high degree of rotational resistance, often achieved through a specific lay construction, is essential to prevent dangerous cage rotation and swinging.

Multi-strand Ropes and Anti-Spin Properties

Some specialized multi-strand ropes are engineered for extreme anti-spin properties.

These ropes utilize complex constructions to create a torque-neutral lay, ensuring that even under immense load, the rope maintains its integrity.

Rope Diameter and Lay Selection Interaction

The size of the rope also plays a role in how its lay direction performs.

Larger diameter ropes, while offering higher strength, can also impart greater torque, making the lay selection even more critical.

Surface Hoisting and Auxiliary Lines

While deep shafts command rigorous attention, even auxiliary lines need careful lay direction consideration.

For less demanding tasks like general material handling or smaller auxiliary hoists, the choice may offer more flexibility but still requires attention to prevent common issues.

Abrasion vs. Rotation Balance

Surface operations might involve more contact abrasion than deep shaft hoisting.

In such cases, a Lang Lay rope, offering better abrasion resistance, might be considered, provided its rotational characteristics are suitable for the specific application.

Winch and Cable Pulling Applications

Winch operations often involve side-pulling or angled lifting.

The lay direction can influence how the rope interacts with the winch drum and the load, affecting control and wear.

Material Handling and Conveyor Systems

Wire ropes used in material handling also have specific needs.

The constant movement and potential for snagging in these systems require a rope that can withstand repetitive stress and abrasion.

Durability and Flexibility for Constant Use

Constant cycling demands a rope that is both durable and flexible enough to handle the motion smoothly.

A well-chosen lay direction can contribute to the overall lifespan and smooth operation of these systems.

Key Factors for Reliable Mine Hoisting Wire Rope

Beyond the lay direction, several other crucial aspects contribute to the reliable performance of wire ropes in mining operations.

Ensuring the rope meets stringent standards, possesses high tensile strength, and is correctly manufactured is foundational to safe and efficient hoisting.

Quality and Standards Compliance

The source and manufacturing quality of your wire rope are non-negotiable.

Reputable manufacturers adhere to international standards, ensuring the rope’s integrity and a predictable performance envelope.

EN12385-4 and Other Certifications

Adherence to standards like EN12385-4 is a strong indicator of quality for hoisting ropes.

These certifications confirm that the rope has undergone rigorous testing and meets specific mechanical properties required for safe hoisting applications.

Material Quality and Construction

The wire itself and the way it is constructed into strands and the final rope are critical.

High-quality steel formulations and precise manufacturing processes contribute to the rope’s high tensile strength and breaking load.

Tensile Strength and Breaking Load

These are the core performance metrics for any load-bearing wire rope.

Understanding the tensile strength and breaking load ensures you select a rope capable of handling the maximum expected load with a sufficient safety margin.

Calculating Required Load Capacity

Properly calculating your operational loads is the first step in selecting the right rope.

This involves factoring in the weight of the cage, the payload, and any dynamic forces that may be encountered during hoisting.

Safety Margins and Factor of Safety

A robust safety margin is essential in mining to account for unforeseen circumstances.

Regulatory requirements and best practices dictate a minimum factor of safety, ensuring the rope’s breaking load significantly exceeds the maximum working load.

Galvanization and Plastic Impregnation

These treatments enhance a rope’s resistance to environmental degradation.

Galvanization protects against corrosion, while plastic impregnation can improve lubrication and reduce internal friction.

Corrosion Protection in Harsh Environments

Mining environments can be humid, wet, and chemically aggressive.

Galvanized ropes and those with plastic impregnation offer superior protection against rust and degradation, extending their service life.

Lubrication and Internal Rope Wear

Internal friction can cause wear between the strands and wires over time, even if external conditions appear mild.

Plastic impregnation helps to maintain lubrication within the rope’s core, reducing internal wear and improving flexibility.

Conclusion

Choosing the correct lay direction for your mine hoisting wire rope is vital for safety and efficiency.

It is a decision that balances rotational control, abrasion resistance, and the specific demands of your mining environment.