Improper wire rope clamping can lead to serious accidents. I’ve seen worksite delays and injuries caused by something as simple as a loose clamp. That’s why I always treat this step with extra care.

To clamp a wire rope correctly, use the right clamp type, apply proper torque, and follow the right installation method according to EN 13411-5 standards.

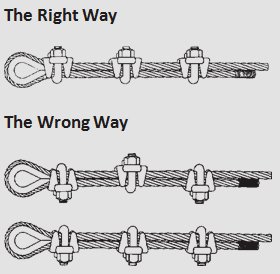

Many people underestimate this process. But missing one small detail — like putting the saddle on the wrong side — can reduce holding strength by up to 40%. This guide will walk you through the essential steps.

What types of wire rope clamps should I use?

Choosing the wrong clamp can lead to slippage or rope damage. It’s not always about the cheapest option — different environments need different solutions.

Use double-saddle clamps for better load distribution, U-bolt clips for temporary needs, and swaged sleeves for permanent, high-load setups.

Dive Deeper: Wire Rope Clamp Types

Here’s a quick breakdown of the most common types:

| Clamp Type | Best Scenario | Pros | Cons |

|---|---|---|---|

| U-Bolt (Wire Rope Clips) | Temporary work, light rigging | Widely used, low cost | Can damage ropes if misused |

| Double Saddle | Lifting and cranes | Even pressure, reusable | Slightly more expensive |

| Swaged Sleeves | Permanent installation | High strength, clean look | Needs special tools |

| Fist Grip Clamp | High-vibration applications | Easier to torque correctly | Takes more space |

Key Considerations:

- Use galvanized types for marine usage.

- Stainless steel is best in corrosive environments.

- Match clamp size to rope diameter exactly.

How many clamps do I need for each rope connection?

This depends on the rope diameter. I remember using only three clamps on a 26mm rope early in my career — it failed during lifting. That mistake taught me to always refer to the standards.

Use at least 3 clamps for ropes under 19mm, 4 to 5 for 20-30mm, and more for larger diameters — spacing should be 6 times the rope diameter.

Clamp Quantity Guide

| Rope Diameter (mm) | Minimum Clamp Quantity | Clamp Spacing |

|---|---|---|

| up to 10mm | 3 | 60–70mm |

| 11–20mm | 4 | 70–120mm |

| 21–30mm | 5 | 120–180mm |

| 31mm+ | 6+ | 180–250mm |

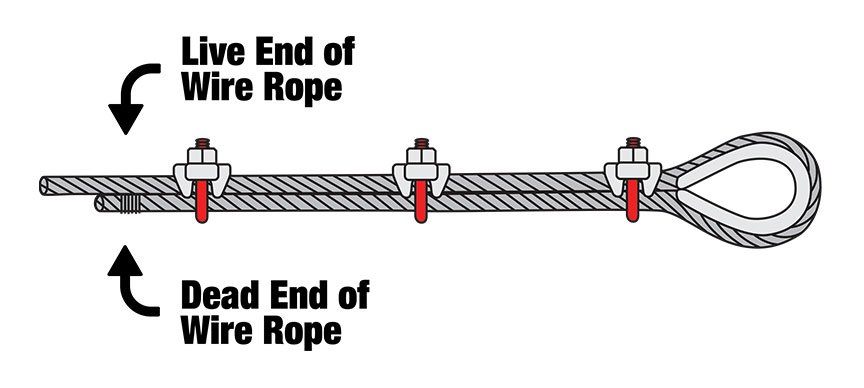

Spacing and direction matter. Always place the U-bolt over the dead end and the saddle on the live end — or as we say, “never saddle a dead horse.”

What is the right torque for fastening wire rope clamps?

Too loose, and the rope slips. Too tight, and the strands get crushed. Applying the right torque ensures safety and rope lifespan.

Follow the manufacturer’s torque values — usually between 35 Nm and 65 Nm depending on clamp size. Always recheck after one load cycle.

Dive Deeper: Sample Torque Table

| Clamp Size | Bolt Size | Recommended Torque (Nm) |

|---|---|---|

| Small | 8mm | 35 |

| Medium | 10mm | 45–50 |

| Large | 12mm+ | 55–65 |

Make sure to:

- Lubricate bolts (not the rope contact area).

- Use a calibrated torque wrench.

- Re-torque clamps after first load use.

I’ve seen dozens of cases where neglecting torque checks caused unexpected failures — especially in cranes working double shifts.

When should I replace wire rope clamps?

Clamps don’t last forever. I inspect mine every project cycle. Regular maintenance prevents small issues from becoming big ones.

Replace clamps if there’s visible corrosion, thread wear, deformation, or after extreme shock loads.

Dive Deeper: Inspection Checklist

- Look for cracked or bent saddles.

- Check if bolts are hard to turn (thread stretch).

- Measure bolt diameter with calipers — 10% loss = replace.

- Replace clamps if they’ve been over-torqued even once.

I usually replace clamps used in salty or wet environments every 12–18 months, even if no damage is visible. It’s cheaper than explaining a failure on-site.

Does rope lubrication affect the clamp’s grip?

Yes. While lubrication is good for rope life, it reduces grip when not handled correctly.

Wipe off any grease or oil before clamping. Only lubricant allowed is on bolt threads to assist torque control.

In one offshore crane, the rope slipped through clamps during load testing. The culprit? Over-lubricated wire strands.

Dive Deeper: Do’s and Don’ts

✅ Do

- Use dry ropes for clamping

- Keep clamp surfaces free of oil

- Apply anti-seize lubricant on screw threads only

❌ Don’t

- Clamp directly over lubricated rope

- Use rope grease on saddle areas

- Ignore re-tightening after the first load cycle

If using plastic-impregnated or galvanized ropes, I also recommend doing a test clamp under load before final installation.

What’s the right way to angle clamps during installation?

The orientation and angle of clamps matter especially in angled pulls or tensioned bends.

Install clamps perpendicular to rope direction, with bolts facing outward for easy inspection — always on straight and untwisted rope segments.

I always mark the saddle side with red paint during installation. This helps my team stay consistent even under pressure.

Dive Deeper: Common Angle Mistakes

- Avoid placing clamps right after bends or thimbles

- Never stack one clamp directly above another

- Keep rope untwisted — twisted clamps reduce holding strength by 20%

How do I test a freshly clamped rope before use?

No one should assume the system works just because it “looks tight.” Testing ensures it’s safe before loading real weight.

Do a pre-load test at 50% of working load limit (WLL), then re-torque all clamps before full use.

In large-scale mining setups, we always suspend load baskets and hold for 5 minutes. This often reveals creeping or rope movement if clamps are not secure.

Dive Deeper: Load Testing Protocol

- Clamp the rope per standard spacing

- Apply controlled test load at 50% WLL

- Hold load for minimum 3 minutes

- Inspect for slippage or deformation

- Re-torque each clamp before next use

I also recommend recording each test with photos. It’s a simple habit that helps during audits or safety reviews.

Conclusion

Wire rope clamping isn’t just about fastening metal parts. It’s a process that combines technique, inspection, and safety awareness to protect both people and equipment. Every clamp, every bolt, every inch of rope counts.