Are you finding the process of ordering steel wire rope complicated? A wrong choice can lead to project delays and a lot of wasted money. I will show you a simple process.

To order steel wire rope, first provide detailed specifications like diameter, construction, and grade. Then, verify the supplier’s certifications and quality control. Finally, confirm all details and place your order.

I remember a client from Australia. He used to source from expensive European brands. He came to us looking for the same high quality but at a better price. His main concern was getting every detail right from the start.

What Key Specifications Must I Provide for My Order?

Providing the right details is the most important step. It helps us give you an accurate price. It also ensures you get the correct product for your needs.

You must provide the wire rope’s diameter, construction, core type (FC or IWRC), tensile strength, and finish. Also, mention the required length, quantity, and lay direction for the order.

Let’s dive deeper into each specification. Getting these details correct is the foundation of a successful order. Each specification tells us something important about the rope you need. It affects the rope’s strength, flexibility, and service life.

Diameter

This is the width of the rope. You should measure it at its widest point. It is usually measured in millimeters (mm) or inches. An incorrect diameter can cause problems with sheaves and drums on your equipment.

Construction

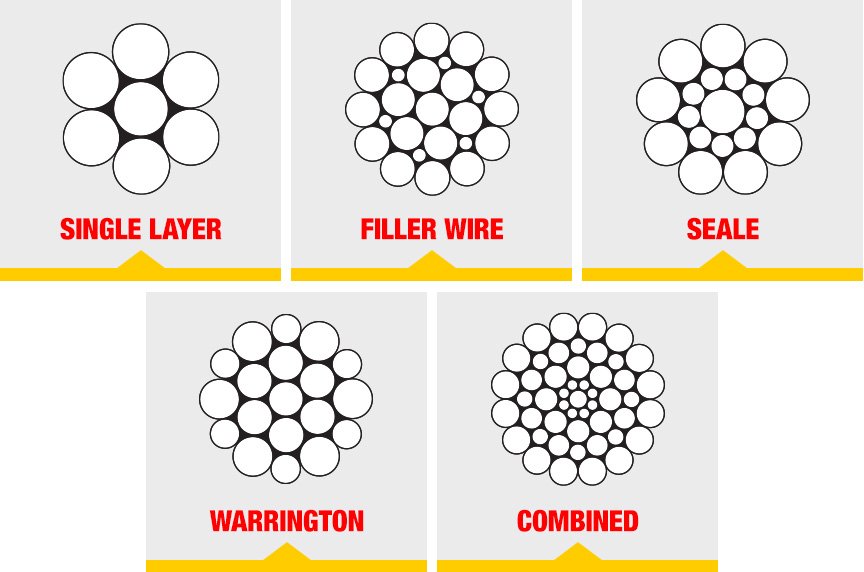

This describes how the rope is made. It is written as “number of strands x number of wires”. For example, a 6×19 construction means the rope has 6 strands, and each strand has 19 wires. Different constructions offer different levels of flexibility and abrasion resistance.

Core (FC vs. IWRC)

The core is the center of the wire rope.

- Fiber Core (FC): This core is made of natural or synthetic fibers. It makes the rope more flexible. It is good for applications where the rope doesn’t face high crushing forces.

- Independent Wire Rope Core (IWRC): This core is a small wire rope itself. It provides more strength and is very resistant to crushing. It is standard for most crane ropes and heavy lifting applications.

Tensile Strength / Grade

This tells you the breaking strength of the rope. It is often measured in Newtons per square millimeter (N/mm²). Common grades are 1770, 1960, and 2160. A higher grade means a stronger rope of the same size. You must match the grade to your equipment’s requirements.

Finish

This refers to the protective coating on the wires.

- Ungalvanized (or Bright): This rope has a light lubricant coating. It is used in environments that are not corrosive.

- Galvanized: Each wire is coated with zinc for corrosion resistance. This is essential for marine, offshore, or outdoor applications. We offer this option.

- Plastic Impregnated (PI): The space between the strands is filled with plastic. This locks in lubrication and keeps out dirt and moisture. It greatly extends the rope’s life. We also provide this special finish.

Quick Specification Checklist

Here is a simple table you can use to prepare your order details.

| Specification | Example | My Notes |

|---|---|---|

| Diameter | 20mm | |

| Construction | 6×36 | |

| Core | IWRC | |

| Grade (Tensile Strength) | 1960 N/mm² | |

| Finish | Galvanized | |

| Length per Reel | 1000 meters | |

| Quantity | 5 reels | |

| Lay Direction | Right Hand Regular Lay (RHRL) |

How Can I Verify a Supplier’s Quality and Certifications?

Price is important, but quality ensures safety and performance. You should always check a supplier’s quality control systems. You also need to check their certifications.

Ask for their Mill Test Certificate (MTC) for the specific batch. Also, request copies of their quality management certificate and any third-party type approvals like DNV, ABS, or RMRS if needed for your industry.

Trust is built on proof. In our industry, that proof comes from documentation and consistent testing. Let’s look at what you should ask for.

The Mill Test Certificate (MTC)

This is the most important quality document for your order. It is also called a “Test Report.” It is a quality assurance certificate. It confirms that the rope meets international standards and its stated specifications.

An MTC should include:

- Manufacturer’s Name (like our brand, Aulone)

- Order Number

- Rope Diameter and Construction

- Actual Measured Diameter

- Minimum Breaking Load (MBL)

- Actual Breaking Load (from destructive testing)

- Standard it conforms to (e.g., EN12385-4)

We provide a detailed MTC with every single order that leaves our factory.

Third-Party Certifications

For some industries, especially marine and offshore, you need more than just an MTC. You need a type approval certificate from a classification society. This proves that the manufacturer’s product line meets very high standards.

Here are some common ones we can provide if you need them:

| Certificate | Industry/Purpose | What It Means |

|---|---|---|

| EN12385-4 | Cranes | A European standard specifically for steel wire ropes for cranes. |

| DNV / ABS / RMRS | Marine & Offshore | Certifies that the ropes are suitable for use on ships and offshore platforms. Issued by classification societies. |

| CE Certificate | General (Europe) | Declares conformity with health, safety, and environmental protection standards for products sold in Europe. |

| BV Certificate | General Industry | Issued by Bureau Veritas, it verifies quality, safety, and compliance across various industries. |

Factory Audits and Inspections

Seeing is believing. You can always ask if you can visit the factory. We welcome clients to our facility to see our four production lines in action. If you cannot visit, you can hire a third-party inspection company to check the products before they are shipped. This gives you extra peace of mind.

What Are the Common Wire Rope Types and Their Applications?

Different jobs need different ropes. Choosing the correct type is critical for a long service life and a safe operation. A crane rope is very different from an elevator rope.

General-purpose ropes like 6×19 and 6×36 are for lifting. Rotation-resistant ropes are for cranes. Elevator ropes are designed for smooth travel. Galvanized ropes are for marine environments.

Let’s break down the most common types of wire rope we manufacture. We will look at their features and where they are used. This will help you select the right product for your business, whether you are in mining, construction, or shipping.

### Common Wire Rope Applications

This table connects rope types to their common uses.

| Rope Type | Key Features | Common Applications |

|---|---|---|

| 6×19 & 6×36 Class | Good mix of flexibility and wear resistance. The workhorse of the industry. | General hoisting, crane ropes, winch lines, slings |

| Rotation Resistant Ropes (e.g., 19×7, 35×7) | Designed to resist spinning under load. Essential for single-part hoisting. | Main hoist lines on mobile and tower cranes |

| Elevator Ropes (e.g., 8x19S) | Very flexible, smooth, and durable. Made for constant bending over sheaves. | Passenger and freight elevators |

| Mining Ropes | Extremely tough, high breaking load. Designed for harsh, abrasive conditions. | Mine hoists, shovels, draglines |

| Galvanized Marine Ropes | Coated with zinc to resist salt water corrosion. | Mooring lines, towing lines, fishing ropes, deck cranes |

| Stainless Steel Ropes | Maximum corrosion resistance. Used in chemical or food environments. | Yacht rigging, architectural use, food processing plants |

| Synthetic Ropes | Very lightweight, strong, and it floats. Safer than steel if it breaks. | Mooring, towing, offshore winch lines |

We have experience producing all these types. We export them to countries like Singapore, Indonesia, Vietnam, and Saudi Arabia for these exact applications.

What Should I Expect for Payment Terms and Shipping?

Understanding payment and shipping is key to a smooth transaction. Let’s talk about the common practices in international trade for wire rope. It is simple once you know the terms.

Common payment terms are 30% T/T deposit and the balance against the copy of the Bill of Lading (B/L). For shipping, you will need to agree on Incoterms like FOB or CIF.

The financial and logistical parts of an order are just as important as the technical specifications. Here is a simple breakdown.

Common Payment Methods

For international trade, payments need to be secure for both the buyer and the seller.

- T/T (Telegraphic Transfer): This is a direct bank transfer. The most common structure is a partial payment upfront and the rest later. A 30% advance payment allows us to start production. The final 70% is often paid after the goods are shipped, when we provide a copy of the shipping document (the B/L). This is a balanced and fair method.

- L/C (Letter of Credit): An L/C is a promise from a bank to pay the seller, as long as the seller meets all the conditions in the document. It is very secure but can be more complex and costly. It is usually used for very large orders.

Understanding Incoterms

Incoterms are standard trade terms. They define who is responsible for the goods at each stage of shipping.

| Incoterm | What It Means |

|---|---|

| EXW (Ex Works) | You (the buyer) arrange all shipping from our factory door. |

| FOB (Free On Board) | We (the seller) handle everything to get the goods loaded onto the ship at the port in China. You handle the ocean freight and everything after. |

| CIF (Cost, Insurance, and Freight) | We handle everything to get the goods to your destination port. The cost of ocean freight and insurance is included in our price. |

We are flexible and can work with the Incoterm that is best for you.

Is It Possible to Customize My Wire Rope Order?

Sometimes a standard product is not enough. Many manufacturers, including us, offer customization. We can meet your specific project needs. This helps you get a product that is perfectly suited for your job.

Yes, you can customize your order. Common requests include specific cut lengths, special end fittings, custom logos on reels, and specialized coatings like plastic impregnation for extra protection.

A standard product is great for many situations. But sometimes a special feature can make a big difference in performance and branding. Here are some of the ways we can customize your order.

Custom Lengths and Packaging

Standard reels are often 500m or 1000m. But you might need exact lengths for a specific crane or project. We can cut ropes to any length you require. We can also package them on different types of reels, like sturdy wooden reels or smaller plastic reels, depending on your needs.

Custom Logo

We can print your company’s logo on the reel. This is great for distributors or large companies who want to reinforce their brand identity. When your team sees the reel on a job site, they see your brand. It is a simple but effective marketing tool.

Plastic Impregnation (PI)

This is a high-value customization. We fill the space between the rope’s strands with a special plastic.

- It locks the factory lubricant inside the rope.

- It keeps out dirt, sand, and water.

- It protects the inner wires from corrosion and friction.

A plastic-impregnated rope can last much longer in harsh environments like mines or ports.

Specialized Assemblies

We can also supply wire rope assemblies. This means the rope comes with end-fittings already attached. These can be sockets, thimbles, or hooks. This saves you time and ensures the fittings are attached correctly and safely.

Conclusion

Ordering wire rope is simple when you follow these steps. Provide clear specs, verify quality, and communicate with your supplier. We are here to help you.