Worried about wire rope reliability? Unsure about safety? Wire rope safety is critical. It protects both your operations and your people.

To ensure wire rope safety, conduct regular inspections. Store and operate them correctly. Always choose high-quality, compliant products.

I once saw an accident from bad wire rope. A worn rope almost dropped a heavy load. This showed me why safety is so important. It’s why I created Aulone. We make ropes you can trust.

Why Is Choosing the Right Wire Rope Crucial for Safety?

Choosing correct wire rope is fundamental for safety. Wrong types or materials cause big problems. The right product ensures safe, stable work. It’s the first safety step.

Choosing right wire rope is crucial for safety. It directly affects load capacity and wear. It also impacts environment fit. This choice prevents immediate and long-term failures.

Different Wire Rope Types and Their Applications

Each wire rope type has a specific design. Knowing these helps selection. Hoisting ropes need high strength. They also need fatigue resistance for cranes. Mining ropes require extreme wear resistance. They work in harsh, abrasive places. Marine ropes need strong corrosion resistance. Saltwater can damage them. We offer galvanized and stainless steel. Some specialized tools, like piling tools, need specific rope types.

| Wire Rope Type | Key Features | Typical Applications | Aulone’s Advantage |

|---|---|---|---|

| Crane Rope | High strength, fatigue resistant | Overhead cranes, mobile cranes | EN12385-4 compliant, high breaking load |

| Elevator Rope | Flexible, smooth, low stretch | Passenger/freight elevators | Precise, plastic impregnated options |

| Mining Rope | High abrasion resistance | Mine shafts, excavators | Durable in tough places, custom sizes |

| Marine Rope | Corrosion resistant | Ships, offshore, fishing | Galvanized, stainless steel versions available |

| Synthetic Rope | Lightweight, strong, buoyant | Marine, specialized lifting | Alternative to steel, non-corrosive |

Material and Environmental Adaptability

Wire rope material impacts its use. Choose wisely for long life and safety. Galvanized ropes suit wet or corrosive places. Zinc protects steel from rust. Good for outdoors or marine use. Stainless steel ropes are for marine or medical fields. They resist corrosion well. Higher cost, but necessary for tough jobs. Plain carbon steel is for dry places. No corrosion worries. High strength, lower cost. Often used indoors. Some ropes are plastic impregnated. The core is filled with plastic. This reduces internal friction. It also prevents inside corrosion. This extends rope life.

The Importance of Standards and Certifications

Ropes compliant with EN12385-4 are tested strictly. These standards ensure quality and performance. Quality is vital for clients like Maksim. He values strong certifications as proof. All Aulone products follow these standards. This is our promise. Quality gives you peace of mind. We provide BV, CE, and RSRM certificates if needed. These are global or industry specific. They show our products meet benchmarks.

How Should Daily Inspection and Maintenance of Wire Ropes Be Performed?

Daily inspection prevents accidents. Regular maintenance makes ropes last longer. Ignoring checks turns small issues into big ones. It’s like regular health check-ups.

Daily inspections check for wear, broken wires, and deformation. They also check for corrosion. Correct maintenance means cleaning, lubricating, and storage. These steps ensure peak performance and longevity.

Key Areas and Signs to Look for During Inspection

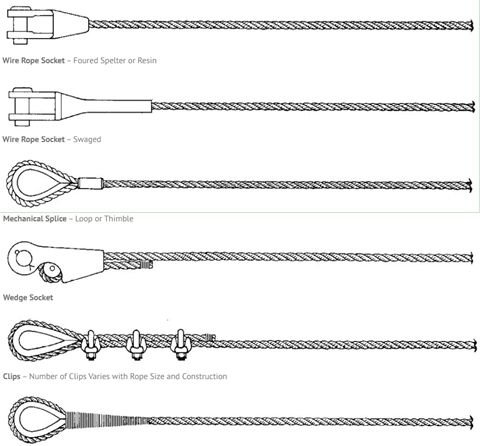

Inspect key wire rope parts. Use a checklist. Check for broken strands or wires. One broken wire warns you. Many broken wires mean replacement. Watch for diameter changes. A smaller diameter means internal damage or looseness. Use calipers to measure. End connections are critical. Check thimbles, splices, and fittings. Look for wear or cracks. Damage here can cause failure. If a rope twists, kinks, or unravels, it is damaged. Kinks reduce strength. A ‘bird cage’ means internal damage.

| Damage Type | Description | Action Required |

|---|---|---|

| Broken Wires | Individual wires snapped. | Count, assess for discard. Maybe replace. |

| Abrasion/Wear | Outer wires flat or thin. | Monitor. Leads to diameter loss. |

| Corrosion | Rust or pitting. | Clean, lubricate. Severe rust needs replacement. |

| Kinks/Bends | Permanent sharp bends or twists. | Discard immediately. Strength is gone. |

| Crushing/Flattening | Rope section flattened. | Discard if bad. Reduces flexibility. |

| Core Protrusion | Internal core pushes out. | Discard immediately. Internal damage. |

| Heat Damage | Discoloration, lubricant lost. | Check for strength loss. Likely discard. |

The Necessity of Lubrication and Cleaning

Lubrication reduces internal friction. Wires move smoothly. This prevents wear. It also prevents corrosion, making a protective barrier. Cleaning removes dirt and grit. These are abrasive. They cause wear if not removed. Apply fresh lube after cleaning. Choose the right lubricant. It must reach inside the rope. It should stick well. Different ropes need different lubricants. Aulone can advise you.

When Is It Time to Replace Wire Ropes?

Knowing when to replace a rope is crucial. Never wait until it breaks. Replace when broken wires exceed limits. For example, six broken wires in one lay. Or three broken in one strand. If diameter shrinks a lot, replace it. It means internal wear. A 5% reduction can trigger replacement. Severe corrosion or deformation mean immediate replacement. Corrosion weakens wires. Kinks and crushing break structure. Always check manufacturer guidelines. Do not risk using damaged ropes. Maksim, our client, values strict quality control. This includes replacing ropes on time.

How to Properly Store and Transport Wire Ropes to Preserve Their Performance?

Correct storage protects wire ropes. Bad storage makes them age fast. Careless transport damages them before use.

Store wire ropes in dry, ventilated areas. Keep them free of corrosive material. For transport, prevent shocks or tangles. Ensure ropes are not crushed or dirty. This keeps their original quality.

Requirements for Storage Environment

The storage area must be dry. Humidity causes rust. Indoor, ventilated spaces are best. Air limits rust. Avoid direct sunlight. UV rays damage coatings. Temperature changes also harm ropes. Keep ropes away from chemicals or fumes. Acids or strong alkalis corrode steel. Store ropes clean and lubricated. This protects them in storage. Place reels or coils on pallets. Don’t put them directly on floors. Store reels on their flanges to prevent crushing.

| Storage Condition | Best Practice | Why It Matters |

|---|---|---|

| Humidity | Low, controlled environment | Prevents rust, corrosion |

| Temperature | Stable, moderate | Stops lube degrading, material stress |

| Light Exposure | Avoid direct sun | Prevents UV damage to coatings |

| Chemical Contact | Away from corrosive chemicals/fumes | Prevents steel degradation |

| Physical Support | On pallets/racks, reels on flanges | Prevents crushing, kinking, ground contact |

| Cleanliness | Clean, lubricated before storage | Maintains protection, prevents abrasive wear |

Transportation Process Considerations

Prevent impacts when moving ropes. Rough handling causes kinks. Kinks reduce strength. Use proper lifting gear. Use wide slings for heavy coils. This prevents crushing. Secure ropes well during transit. Use strong straps to prevent movement. Movement causes chafing. Avoid sharp objects. They can cut or scratch ropes. Keep ropes clean and covered. Protect them from dirt or rain. For long or special ropes, use dedicated transport. This minimizes stress.

Packaging and Marking Standards

Aulone ropes are professionally packed. This keeps them high quality. We use moisture-proof wraps. Also sturdy wooden reels or coils. These protect ropes from environment. They guard against moisture and dirt. Packaging has clear markings. These include rope specs, length, and production date. Our brand, Aulone, and lot number are present. These markings help your inventory. You can quickly identify and track products. Clear marking prevents errors. It also improves safety. For clients like Maksim, good marking means traceability and compliance.

Conclusion

To ensure wire rope safety, choose the right product. Inspect and maintain it daily. Store and transport it correctly. These steps are key for operation safety and efficiency.