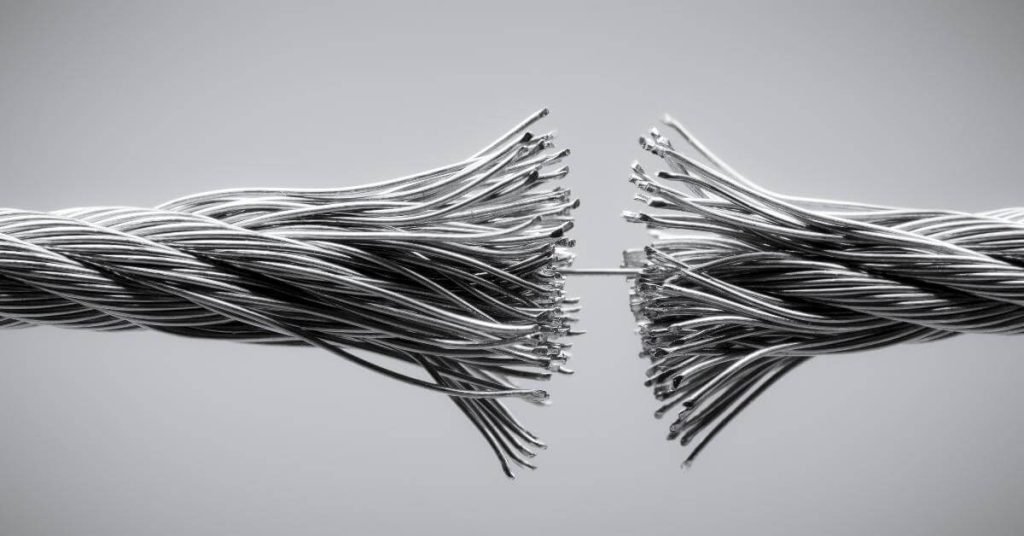

Cutting thick steel wires risks injury and wasted material. Poor tools cause frayed strands or snapped cables on construction sites. Our team’s 25 year rope expertise solves this with proven techniques I’ll share

You need thermal cutters for diameters over 20mm or hydraulic shears for clean cuts, selecting tools based on rope thickness and workplace safety rules. Always wear Kevlar gloves and verify tool certifications first.

When our Vietnam client avoided equipment checks, a collapsed strand delayed their port project. Learn proper methods below to prevent such failures.

What Tools Work Best for Different Wire Rope Sizes?

Choosing tools prevents fraying and saves time. Thinner ropes need simpler solutions, while industrial cables require heavy equipment.

For ropes below 10mm, use bolt cutters like a crane operator would for repairs. Above 10mm, hydraulic shears deliver precision cuts, and above 30mm requires specialized thermal tools.

Three Key Tool Categories Compared

| Tool Type | Best For | Cutting Capacity | Risks if Misused |

|---|---|---|---|

| Bolt cutters | Ropes ≤10mm (e.g., theater rigging) | Manual pressure only | Crushed strands without proper blade alignment |

| Hydraulic shears | 10-30mm diameter (e.g., mining cables) | Up to 300kN force | Leaking fluid causes slippage |

| Thermal cutters | Industrial ropes >30mm | Unlimited, heat-based | Metal splash without face shields; requires fireproof mats |

For premium galvanized ropes like ours, sharp corrosion-resistant blades prevent coating damage. Our DNV-certified ropes maintain integrity when cut correctly.

How Do Safety Protocols Prevent Worksite Accidents?

Ignoring safety measures turns routine cuts into emergencies. Every year, rope snapbacks cause fractures.

Secure both rope ends with vise clamps first, then measure the cutting point twice. Never work in windy areas or exceed equipment weight limits. Hot cuttings from thermal tools require fire safety gear. We supply RMRS-grade ropes tested to avoid sudden brittleness.

Critical Pre-Cut Steps Checklist

| Step | Equipment Needed | Time Required | Why It Matters |

|---|---|---|---|

| Rope stabilization | 2+ vise clamps with rubber pads | 3-5 minutes | Prevents tension release injuries |

| Worksite assessment | Wind meter, clearance markers | 2 minutes | Reduces flammable dust ignition |

| Tool calibration | Pressure gauge, angle protractor | 5 minutes | Avoids costly cutting deviations |

Our steel wire ropes have built-in tensile strength markers for easier measurement. Australian mining clients report 40% fewer incidents since adopting our methodology.

What Post-Cutting Steps Ensure Long-Term Reliability?

Improper finishing causes unraveled wires in machinery. Moisture seeps into untreated ends.

Seal cuts instantly with zinc spray or epoxy. For marine ropes, immerse in plastic impregnation to prevent salt corrosion within one hour.

Conclude by storing vertically away from UV light. Our specialized assemblies include cutting kits that help maintain breaking load guarantees.

Conclusion

Match tools to rope size, prioritize clamping safety, and seal ends properly. Implement these steps for consistent results.