Are you facing challenges with wire rope performance in your piling operations? It’s frustrating when your equipment isn’t working at its best, potentially costing you time and money. Many grapple with finding the perfect wire rope that balances durability and efficiency.

Choosing the right wire rope for your piling machinery is crucial. It directly impacts your operational efficiency and, more importantly, the safety of your project. Getting this choice right means ensuring your equipment performs reliably under demanding conditions.

So, let’s dive into what makes a wire rope suitable for the tough world of piling. I’ll guide you through the key considerations, drawing from my experience to help you make the best choice for your valuable equipment.

What Makes a Wire Rope Suitable for Piling Machine Applications?

When it comes to piling machines, understanding the specific demands of the job is key. The wire rope needs to handle challenging environments, ensuring both performance and longevity.

For piling machines, the ideal wire rope must offer superior resistance to rotation and wear. These machines often work in abrasive conditions, like muddy environments, and deal with heavy loads and frequent rotation, all of which stress the rope.

Understanding the Core Requirements

The demands placed on wire ropes used in piling machines are significant and multi-faceted. These ropes are not just simple lifting cables; they are critical components subjected to extreme forces and environmental factors.

1. Structural Design: Balancing Anti-Rotation and Wear Resistance

Piling machines involve significant rotational forces, especially from the drill string. Therefore, an anti-rotational structure is paramount.

Recommended Structural Types

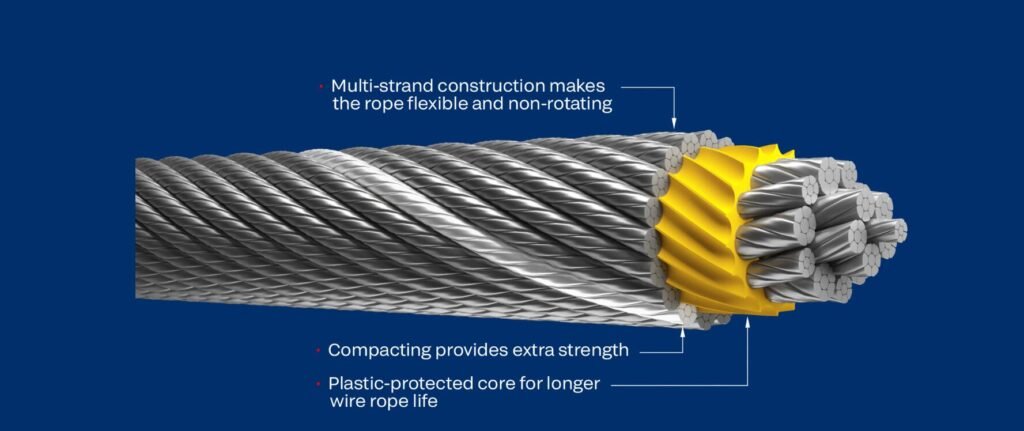

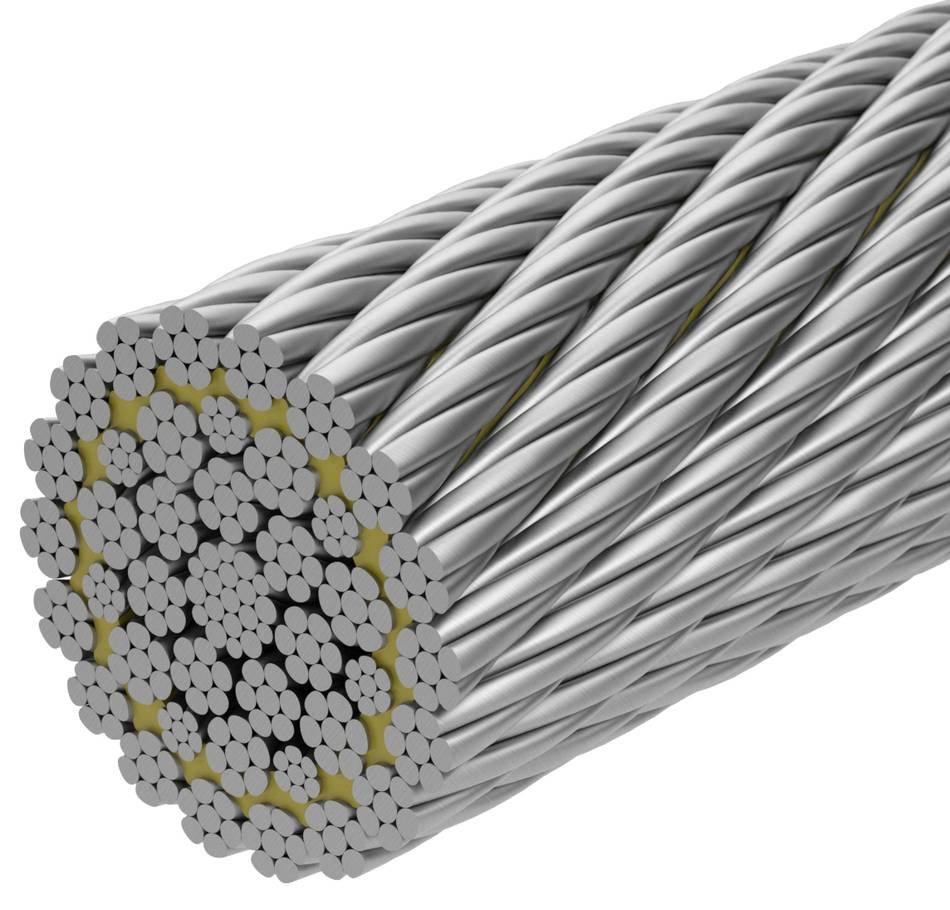

- 35W×K7/37W×K7: This design features multiple layers of strands with a compacted surface. This structure offers excellent resistance to rotation and wear. It’s particularly well-suited for environments with abrasive materials like stones and moderate mud. The line contact design between the wires also reduces friction, leading to a longer service life.

2. Material and Surface Treatment: Combating Corrosion and Abrasion

The operating environment for piling machines often involves mud and potentially acidic or alkaline substances. This necessitates enhanced corrosion and wear resistance for the wire rope.

Galvanized Wire Ropes: A zinc coating on the steel wires provides a degree of protection against corrosion. This is beneficial in scenarios where the rope frequently encounters muddy, wet conditions.

Core with Plastic Layer: For enhanced durability and performance, ropes with an independent steel core (IWRC) are recommended. The inclusion of a plastic layer within the core not only improves resistance to crushing but also helps prevent deformation when the rope is multi-layered on the drum. A specific recommendation here is the 35WXK7-EPWSC type.

3. Diameter and Strength: Matching Equipment and Operational Needs

Correctly sizing the wire rope is essential for matching the equipment’s specifications and the operational demands.

Diameter Selection:

- Common diameters range from 24mm to 56mm.

- The selection must consider the dimensions of the machine’s drums and pulleys.

Rope Groove Matching:

- The ratio of the drum diameter (D) to the wire rope diameter (d) should be at least D/d ≥ 20.

- The groove diameter of the pulley should be 5% to 10% larger than the wire rope diameter. This ensures reduced bending stress and minimizes crushing wear on the rope.

Flexibility and Strength Considerations:

- Tensile Strength: For standard piling operations, a tensile strength of at least 1770 MPa is recommended. For environments with hard rock or high impact loads, increasing this to 2160 MPa is advisable.

- Safety Factor: When dealing with heavy single-line pulls, incorporating a safety factor is crucial to prevent overload and premature breakage.

How Does Wire Rope Selection Impact Piling Efficiency and Safety?

The chosen wire rope significantly influences how efficiently and safely your piling operations run. A well-selected rope can prevent costly downtime and ensure personnel safety.

A poorly chosen wire rope can lead to premature wear, kinking, or even breakage, causing production delays and safety hazards. Conversely, the right rope guarantees reliability, prolongs equipment life, and boosts overall productivity.

Let’s explore how these factors play out in practice and why making the informed decision is so important for your business.

The Tangible Benefits of Proper Wire Rope Selection

When you invest in the correct wire rope for your piling machines, you unlock a range of operational advantages. It’s not just about having a rope that works; it’s about having one that excels under pressure.

1. Enhanced Operational Efficiency

- Reduced Downtime: Ropes designed for high wear and corrosion resistance last longer, meaning fewer interruptions for replacements.

- Consistent Performance: Anti-rotational properties ensure the machine operates smoothly without common issues like cable twisting, which can slow down drilling.

- Load Capacity: Correct strength and diameter ensure the rope can handle the required loads without strain, allowing for more efficient drilling or lifting.

2. Improved Safety Standards

- Minimized Breakage Risk: Adhering to recommended strength and safety factors significantly reduces the risk of rope failure, which is a critical safety concern.

- Predictable Performance: Ropes that meet standards like EN12385-4 provide a level of assurance about their load-bearing capabilities and construction.

- Certifications: Having certifications like BV, CE, RMRS, DNV, or ABS available upon request can be vital for clients in certain regions or industries, adding an extra layer of trust and compliance.

3. Cost-Effectiveness Over Time

- Extended Lifespan: While initial costs might be higher for premium, specialized ropes, their longer operational life translates to lower overall costs per hour of use.

- Reduced Maintenance: A more robust rope typically requires less frequent inspection and maintenance beyond standard procedures.

- Lower Risk of Secondary Damage: Rope failure can damage the piling machine itself. Using the correct rope mitigates this risk.

Critical Factors to Consider for Piling Machine Wire Ropes

To ensure optimal performance and safety, several key factors must be evaluated when selecting wire ropes for piling applications. These considerations help tailor the choice to your specific operational environment.

1. Understanding the Working Environment

- Abrasion: Is the job site prone to sand, gravel, or other abrasive materials? This calls for compacted ropes or those with higher tensile strength.

- Corrosion: Will the rope be exposed to saltwater, chemicals, or constant mud immersion? Galvanization or specialized coatings become important.

- Temperature: Extreme temperatures can affect the rope’s flexibility and strength.

2. Matching Rope to Machine Specifications

- Drum and Pulley Sizes: As mentioned, the D/d ratio is critical. Using a rope that is too large or too small for the existing equipment can cause rapid wear.

- Machine Type: Rotary drilling rigs, hydraulic grabs, and other piling equipment have slightly different stress patterns on the wire rope.

3. Performance Requirements

- Lifting vs. Drilling: While both require strength, drilling often involves more torsional stress and impact.

- Frequency of Use: Heavy-duty applications demand more robust construction.

4. Regulatory and Certification Needs

- For international projects or specific large corporations, certain certifications might be mandatory for the wire rope. Always confirm these requirements upfront.

How Can You Ensure Your Wire Rope Supplier Meets Your Needs?

Selecting the right wire rope is only half the battle; partnering with a supplier who understands your needs is equally vital. Your supplier should be more than just a vendor; they should be a technical partner.

A reliable supplier will offer expert advice, provide compliant and high-quality products, and be transparent about certifications and material specifications. They should also be able to offer customization, such as branding your logo.

Let’s look at how to gauge if a supplier is truly equipped to support your piling operations effectively.

Partnering with a Reputable Wire Rope Manufacturer

Choosing a manufacturer with a strong track record and robust production capabilities is essential. Consider elements that build trust and ensure product integrity.

1. Quality Control and Compliance

- Certifications: Reputable manufacturers can provide necessary certifications (like CE, ABS, DNV) for their products, demonstrating compliance with international standards. They also often adhere to specific standards like EN12385-4.

- Testing Facilities: Do they have in-house testing capabilities to verify tensile strength, breaking load, and other critical parameters?

- Traceability: Can they trace each batch of wire rope from raw material to finished product?

2. Production Capacity and Customization

- Manufacturing Lines: Having multiple production lines, like the four mentioned, indicates a capacity to handle larger orders and different product types efficiently.

- Customization Options: The ability to offer custom logo branding or specialized rope constructions (like plastic impregnated or galvanized options) shows flexibility.

3. Export Experience and Market Reach

- Global Presence: A manufacturer exporting to countries like Singapore, Indonesia, Vietnam, Saudi Arabia, UAE, Russia, and Australia demonstrates a proven ability to meet diverse international quality and logistical requirements.

- Understanding of Regulations: Experience in different markets means they are likely familiar with various import regulations and quality expectations.

4. Technical Support and Customer Service

- Expert Advice: Do they have technical sales teams who can discuss your specific application and recommend the best product?

- Responsiveness: How quickly do they respond to inquiries and resolve issues?

Conclusion

Selecting the correct wire rope for piling machines is a critical decision that impacts both operational efficiency and project safety. It requires a thorough understanding of the specific demands of piling work, including environmental factors and the machinery’s technical specifications. By prioritizing structural integrity, material quality, and appropriate strength, you can ensure reliable performance. Furthermore, partnering with a reputable manufacturer that offers certifications, customization, and expert technical support is paramount. This strategic approach guarantees you receive a wire rope that not only meets but exceeds the rigorous requirements of piling applications, ultimately saving you time, money, and ensuring a safer working environment for everyone involved.