Your crane’s auxiliary hoist seems small. But picking the wrong wire rope can cause delays or safety issues. This guide will help you make the right choice simply and safely.

To choose the right wire rope for an auxiliary hoist, you must match the rope to the hoist’s specific needs. Focus on flexibility, fatigue resistance, and environmental protection. Select a construction like 6×36 or an 8-strand rope with the correct diameter.

I remember a client from Australia who faced constant issues. He was using a rope that was too stiff for his auxiliary hoist. It frayed quickly. This small mistake cost him a full week of downtime. Let’s make sure that never happens to you.

What is the Primary Role of an Auxiliary Hoist on a Crane?

The auxiliary hoist is often overlooked. But it performs crucial tasks every day. It is the crane’s partner for smaller and faster lifts, making the whole operation more efficient.

An auxiliary hoist is a secondary lifting mechanism on a crane. It is designed to handle lighter loads at a much higher speed than the main hoist. It improves efficiency for tasks that don’t need the main hoist’s full capacity.

The main hoist on a ship or offshore crane is for the heavy lifting. It can lift many tons, but it is slow. The auxiliary hoist is the opposite. It lifts lighter loads, but it is much faster. This speed is its main advantage. Think of it as the difference between a long-haul truck and a small delivery van. Both are useful, but for different jobs.

The Speed and Efficiency Advantage

Speed is very important in marine operations. Time is money. Using the large main hoist to lift a small toolbox or a pallet of supplies is very inefficient. The auxiliary hoist can do this job in a fraction of the time. This frees up the main hoist for the heavy lifts it was designed for. An efficient operation is a profitable operation.

Common Applications

The auxiliary hoist is very versatile. Its high speed makes it perfect for a variety of tasks on a vessel or platform.

Here are some common uses:

| Application | Description |

|---|---|

| Lifting Tools & Spares | Quickly moving toolboxes, spare parts, and small equipment onto the deck or platform. |

| Personnel Transfer | Safely lifting and lowering personnel in an approved man-riding basket. |

| Handling Provisions | Moving food, water, and other daily supplies from a supply vessel. |

| Small Cargo Lifts | Handling smaller cargo nets or containers that are below the main hoist’s optimal load. |

How Do Main and Auxiliary Hoist Ropes Differ in Specification?

A main hoist rope and an auxiliary hoist rope are not interchangeable. Their designs are fundamentally different. They are built for separate jobs and have very different characteristics.

Main hoist ropes are large and built for maximum strength to handle heavy loads. Auxiliary hoist ropes are smaller, more flexible, and designed for high speed and resistance to bending fatigue over smaller sheaves.

Some people think a wire rope is just a wire rope. I had a client in Singapore who tried to use a leftover piece of main hoist rope on his auxiliary hoist. The rope failed in less than a month. The rope was too stiff for the small sheaves on the auxiliary system. It bent too sharply and the wires broke. This shows why understanding the differences is so important for safety and rope longevity.

Diameter and Breaking Load

The most obvious difference is size. Main hoist ropes have a larger diameter. This is because they need a very high Minimum Breaking Load (MBL) to lift heavy objects safely. An auxiliary hoist lifts lighter loads. So, its rope can have a smaller diameter and a lower MBL. Using a rope that is too big is just as bad as using one that is too small.

Flexibility and Sheave Size

Flexibility is a key factor. Auxiliary hoists usually have smaller sheaves and drums. A sheave is the grooved wheel that the wire rope passes over. A stiff rope running over a small sheave will experience extreme bending stress. This causes the wires inside the rope to fatigue and break very quickly. Auxiliary hoist ropes must be very flexible to handle these tight bends at high speed.

Construction and Fatigue Resistance

The internal construction of the rope determines its flexibility and fatigue resistance. Ropes with more smaller wires are more flexible. For example, a 6x36 construction is more flexible than a 6x19 construction because it has more wires per strand. Auxiliary hoist ropes use constructions that provide this flexibility.

Here is a simple table to show the main differences:

| Feature | Main Hoist Wire Rope | Auxiliary Hoist Wire Rope |

|---|---|---|

| Primary Use | Heavy, slow lifts | Light, fast lifts |

| Diameter | Large | Small to Medium |

| Key Property | High Breaking Strength | High Flexibility & Fatigue Resistance |

| Construction | Often fewer, larger wires (e.g., 6x25) | Often more, smaller wires (e.g., 6x36, 8x25) |

| Sheave Size | Large | Small |

Which Environmental Factors Influence Auxiliary Rope Selection?

A crane in the humid climate of Indonesia faces different challenges than one in the cold waters of Russia. Your working environment directly affects the wire rope. You must choose a rope with the right protection.

The most important environmental factors are saltwater, humidity, and extreme temperatures. For marine environments, a galvanized or stainless steel rope is necessary to fight corrosion. Plastic impregnation offers even better protection.

We have a customer with a fleet in the UAE. The combination of saltwater spray and fine sand was destroying their ropes. The salt caused corrosion from the outside. The sand got inside the rope and acted like sandpaper, grinding away the wires. We recommended a plastic-impregnated galvanized rope. This solved their problem and doubled the rope’s service life.

The Challenge of Corrosion

Saltwater is the biggest enemy of steel wire rope. It causes rust and corrosion that weaken the rope from the outside in. Even high humidity can cause problems over time.

- Galvanization: This is a standard solution. A layer of zinc is applied to the wires. The zinc corrodes first, sacrificing itself to protect the steel. This is a very effective and common method. Our factory produces high-quality galvanized ropes that meet international standards.

- Stainless Steel: For the most extreme environments, stainless steel ropes offer the best corrosion resistance. They are more expensive, but sometimes they are the only option. We can supply these for specialized applications.

Extreme Temperatures

Temperature affects both the steel and the rope’s lubricant.

- Cold: In very cold places, like the Arctic or parts of Canada, steel can become brittle. The lubricant can also get thick and fail to protect the rope’s core. You need a rope with the right steel grade and a special lubricant for low temperatures.

- Heat: In hot places like Saudi Arabia, the lubricant can become thin and drip out of the rope. This leaves the core dry and unprotected. A rope with a high-temperature lubricant is necessary.

Abrasives and Contaminants

Sand, dust, and other particles can get inside a wire rope. As the rope bends and moves, these particles grind against the wires. This causes internal abrasion, which is very difficult to detect through visual inspection.

| Environmental Challenge | Recommended Rope Feature | Why It Matters |

|---|---|---|

| Saltwater Spray / High Humidity | Hot-Dip Galvanization | Provides a protective zinc layer to prevent rust. |

| Extreme Corrosion | Stainless Steel or Plastic Impregnation | Offers maximum protection against rust and chemical attack. |

| Sand, Dust, Grit | Plastic Impregnation | Seals the rope, preventing particles from entering and causing internal wear. |

| Extreme Cold / Heat | Specialized Lubricant | Ensures the lubricant remains effective at operational temperatures. |

What Are the Ideal Wire Rope Constructions for Auxiliary Hoists?

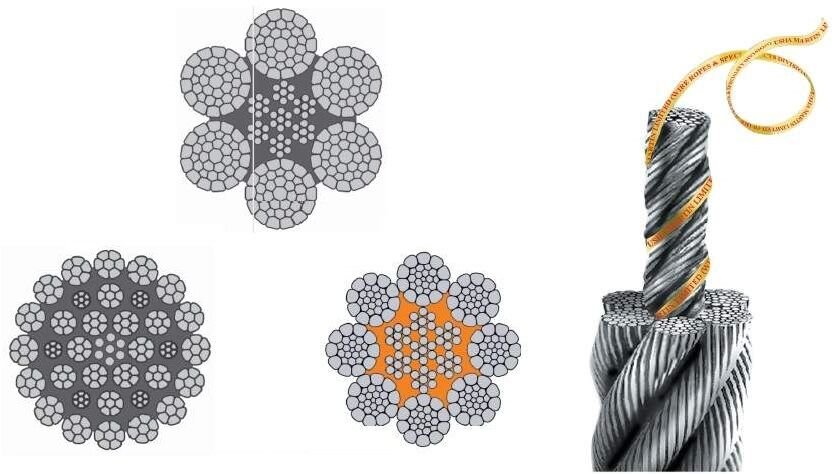

Not all wire ropes are made the same. The internal arrangement of wires and strands is called its “construction.” This construction determines the rope’s flexibility, crush resistance, and fatigue life.

For auxiliary hoists, flexible constructions like 6x36 Warrington Seale (WS) or 8-strand ropes like 8x25 Filler Wire (FW) are ideal. They provide the fatigue resistance needed for high-speed work over small sheaves.

Choosing the construction is about finding the right balance. You need a rope that is flexible enough to bend. But you also need one that is strong enough to resist getting crushed on the drum. It’s a technical choice, but a very important one. Our production lines can create many different constructions to meet our clients’ specific needs.

Understanding Rope Construction

A wire rope’s name describes its structure. For example, a 6X36 rope means:

- 6: It has 6 strands.

- 36: Each strand is made of approximately 36 wires.

A rope with more wires is generally more flexible. A rope with fewer, larger wires is more resistant to abrasion.

Why 6×36 Warrington Seale (WS) is Popular

The 6X36WS-IWRC class is a workhorse for many crane applications, including auxiliary hoists.

- Flexibility: It has a high number of wires per strand, making it very flexible. This is perfect for the small sheaves on auxiliary hoists.

- Fatigue Resistance: Because it bends easily, it suffers less from bending fatigue. This gives it a longer service life in high-speed, repetitive lifting cycles.

- Good Balance: It offers a good compromise between flexibility and abrasion resistance.

The Case for 8-Strand Ropes (e.g.,8X25)

8-strand ropes are an excellent upgrade for many auxiliary hoists. They have eight strands wrapped around the core instead of the usual six.

- Superior Flexibility: With more strands, these ropes are even more flexible than 6-strand ropes.

- Excellent Fatigue Life: They perform extremely well on multi-layer spooling systems where ropes can crush against each other. The rounder shape and flexibility help reduce this damage.

- Increased Contact Area: The eight strands provide a larger contact area with the sheave, which can reduce wear on both the rope and the sheave.

Do You Need a Rotation-Resistant Rope?

For most auxiliary hoist applications, a standard 6x36 or 8x25 rope is sufficient. However, if you are lifting a single part of line from a great height, the load may spin. In this case, a rotation-resistant (RR) or non-rotating rope might be necessary. These are more complex ropes and have special inspection requirements. It is best to consult with an expert, like our team at Aulone, to see if you need one.

Why Must Your Auxiliary Hoist Rope Have Proper Certification?

A cheap rope without a certificate is a huge liability. Certifications are not just paperwork. They are your proof that the rope is safe, reliable, and made to a specific standard.

Certifications from bodies like DNV, ABS, or RMRS, and compliance with standards like EN 12385-4, are critical. They guarantee the rope meets strict international requirements for its material, construction, and breaking load, ensuring safety and legal compliance.

I once worked with a purchasing manager for a large mining company. His director asked him to save money on wire ropes. He bought cheaper, uncertified ropes. One of them failed a site inspection before it was even used. The project was delayed for two weeks while they waited for certified ropes to arrive. The “savings” ended up costing the company thousands of dollars. This is why we always emphasize the importance of certification. We can provide certificates from BV, CE, RMRS, DNV, and ABS if our client needs them.

What is EN 12385-4?

EN 12385-4 is a European standard. It is titled “Steel wire ropes – Safety – Part 4: Stranded ropes for general lifting applications.” This standard is recognized globally. It specifies the requirements for safe manufacturing, testing, and materials for lifting ropes. If your rope is compliant with EN 12385-4, you know it has met a high benchmark for quality.

Understanding Third-Party Certifications

Third-party certifications are verifications from independent classification societies. They are trusted by industries and regulators worldwide. Their inspectors may visit the factory, witness tests, and review quality control documents before issuing a certificate.

Here are some common ones we provide:

| Certification Body | Primary Focus / Region |

|---|---|

| DNV (Det Norske Veritas) | Global, very strong in marine, offshore, and energy sectors. |

| ABS (American Bureau of Shipping) | Global, very strong in the Americas and marine industries. |

| RMRS (Russian Maritime Register of Shipping) | Focused on ships and equipment for use in Russia and related regions. |

| BV (Bureau Veritas) | French origin, global reach in testing, inspection, and certification. |

| CE Marking | A declaration that the product meets EU standards for health, safety, and environmental protection. |

The Real Cost of Non-Compliance

Using a non-certified rope is a risk.

- Safety: The rope may not perform as expected. This can lead to accidents.

- Legal & Insurance: In case of an accident, an insurance company might deny a claim if a non-certified rope was used. You could also face legal penalties.

- Operational: Your equipment could be shut down by inspectors. It could be rejected by a client. This leads to costly downtime and damages your reputation.

How Does Plastic Impregnation Benefit an Auxiliary Hoist Rope?

Imagine your wire rope having its own internal and external shield. That is what plastic impregnation provides. It is an advanced feature that significantly improves a rope’s performance and lifespan.

Yes, plastic impregnation (PI) dramatically extends rope life. It seals the core lubricant in and blocks saltwater, sand, and grit from getting inside. This greatly reduces internal corrosion and abrasion, which are primary causes of rope failure.

The plastic is not just a coating on the outside. During manufacturing, a special polymer is forced into the rope. It fills the empty spaces between the strands and around the core. This creates a stable and protected rope structure from the inside out. Our factory offers high-quality plastic impregnation for ropes that will be used in the toughest conditions.

Sealing in Lubricant

A wire rope is a machine with many moving parts. It needs lubricant to reduce friction between the wires and strands. Over time, this lubricant can get squeezed out or dry up. A plastic-impregnated rope locks the factory lubricant into the core. This ensures the rope stays lubricated for its entire service life.

A Barrier Against Contaminants

This is the biggest benefit for offshore and marine cranes. The plastic layer forms a barrier.

- It stops saltwater and moisture from reaching the steel core, preventing internal corrosion.

- It stops sand, dirt, and other abrasive particles from getting inside the rope. This prevents the internal grinding that wears a rope out from within.

Improved Structural Stability

The plastic fills the internal voids. This provides extra support for the strands. It helps the rope maintain its round shape, especially when spooled on a drum. This reduces the crushing damage that can happen in multi-layer spooling systems. It also reduces the friction between the rope and the sheaves.

Here are the key benefits summarized:

| Benefit of Plastic Impregnation | How It Works |

|---|---|

| Longer Service Life | Reduces internal corrosion and abrasion, the main killers of wire rope. |

| Lower Maintenance | The rope is permanently lubricated, reducing the need for manual re-lubrication. |

| Better Performance | Maintains structural stability and resists crushing, especially in harsh conditions. |

For any auxiliary hoist operating in a marine, dusty, or corrosive environment, a plastic-impregnated rope is a smart investment. It may cost more initially, but it saves a lot of money in the long run through longer life and less downtime.

Conclusion

Choosing the right auxiliary hoist rope is simple. Focus on flexibility, environmental protection, and certified quality. This ensures operational safety and maximizes your crane’s efficiency every day.