Are you finding it tough to zero in on the perfect wire rope for your crawler crane? It’s a question that weighs on many lifting professionals. Making the wrong choice often leads to unexpected downtime and potential safety hazards, which is a nightmare for any purchasing manager.

Selecting the right wire rope is more than just comparing technical specs. Actually, it’s about ensuring a seamless compatibility between the rope and the equipment it serves. This means that customized solutions designed for the specific needs of different industries and machines are absolutely critical. I’ve seen this firsthand in my years of experience.

I remember a project in Southeast Asia where a standard ropes were used for a specialized lifting job. The crane operator explained that while the rope met basic load requirements, the frequent bending at high speeds caused premature wear. This led to more frequent replacements than anticipated, impacting their project schedule and budget. It really highlighted for me how often the “good enough” rope isn’t good enough in the long run.

Beyond the Catalog: Why Do Hoist and Luffing Wire Ropes Need Such Different Approaches?

When we talk about crawler cranes, it’s easy to lump all wire ropes together. But understanding the unique demands placed on each type is where true optimization lies.

The hoist wire rope handles the critical vertical lift, enduring immense shock loads and constant winding. The luffing wire rope, on the other hand, is all about smooth articulation, managing the dynamic forces of boom extension and retraction.

Dive Deeper into the Distinct Needs of Hoist and Luffing Wire Ropes

Wire rope selection isn’t just about the rope’s parameters and manufacturing process; it’s fundamentally about how perfectly it adapts to the application’s equipment. Therefore, differentiated solutions tailored for various industries and equipment are paramount.

We will delve into the selection process for widely used equipment across various specialized industries, aiming to provide clear answers and insights for your specific questions.

Crawler cranes are workhorses in infrastructure development and heavy lifting scenarios. The wire ropes they use for hoisting and for luffing, due to their differing roles, have vastly different selection requirements. This article, drawing from industry standards and practical engineering experience, aims to break down the key selection points for both types of wire ropes. Our goal is to help users precisely match their needs, thereby ensuring both operational safety and peak efficiency.

1: Hoist Wire Rope Selection: Mastering the Balancing Act Between Anti-Rotation and High Tensile Strength

The hoist wire rope is directly responsible for lifting the load. It must withstand dynamic stresses, repetitive coiling onto the drum, and the impact of sudden stops or starts. Therefore, when selecting, we must prioritize its ability to resist rotation and its overall tensile strength.

Unpacking the Best Structural Choices for Hoist Ropes

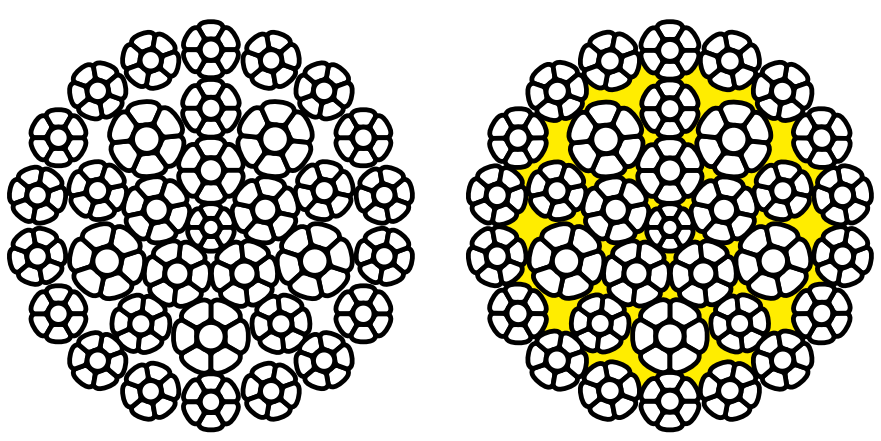

- The Power of 35W×K7/37W×K7 Structure: What makes these structures stand out is their innovative design. The inner and outer strands are spun in opposite directions. This ingenious arrangement helps counteract the rotational torque that can build up as the rope is loaded and unloaded. This significantly reduces the risk of the rope twisting or developing a “bird-caging” effect, where wires pop out of the core. This design is particularly advantageous for lifting operations where the load isn’t guided, providing far more stability.

- The Advantage of Compacted Strand Wire Ropes: These ropes offer a distinct benefit through their design. The strands themselves are compacted, meaning the wires within each strand have more consistent contact (line contact). This design not only increases the wire rope’s overall diameter for a given core, but crucially, it reduces internal friction between the wires. A smoother internal operation translates directly to enhanced wear resistance, making these ropes ideal for situations involving frequent winding onto the drum and for high-layer spooling where ropes are layered upon each other.

Aligning Strength with Industry Standards

- Tensile Strength: A Critical Minimum: For general hoisting duty, I strongly recommend a tensile strength of no less than 1960 MPa. However, for more demanding applications, such as when lifting heavy precast concrete elements or when the crane is subjected to significant shock loads, I would advise opting for ropes with a tensile strength of 2160 MPa. This provides a greater margin of safety and durability.

- The Importance of the Safety Factor: In standard lifting operations, a safety factor of 5:1 (meaning the rope’s breaking strength is five times the working load limit) is typically the minimum requirement. But, when the load being lifted could pose a greater risk if dropped, such as in the transport of hazardous materials or in especially high-risk demolition work, we need to increase this safety factor. Ideally, it should be raised to between 6:1 and 8:1. This additional buffer is crucial for mitigating potential catastrophic failures.

2: Luffing Wire Rope Selection: The Art of Balancing Extreme Flexibility with Robust Fatigue Resistance

The luffing wire rope, tasked with controlling the angle of the crane’s boom, is subjected to a very different kind of stress. It experiences constant bending as the boom moves up and down, along with fluctuating dynamic loads. Therefore, for these ropes, the primary focus during selection must be on their inherent flexibility and their ability to resist fatigue over many cycles of operation.

Exploring Optimal Structural Choices for Luffing Ropes

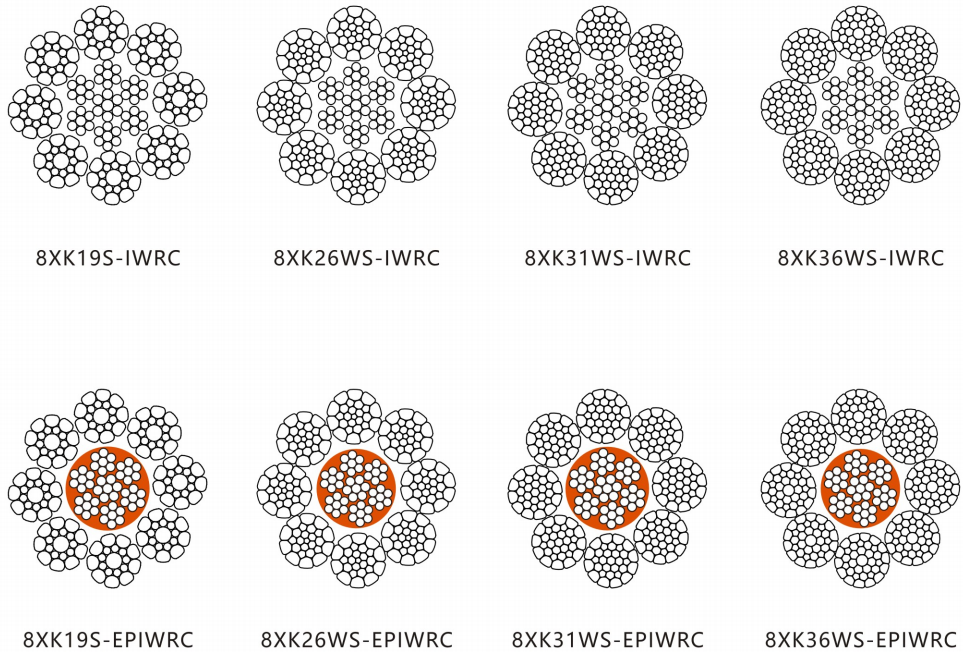

- Standard Rope Strand Designs: Our experience shows that rope structures utilizing finer wires, such as the 8×K26WS configuration, are exceptionally well-suited for the high-frequency bending that luffing ropes endure. The larger number of smaller diameter wires within the strands allows the rope to flex more easily, significantly improving its resistance to fatigue failure. This means the rope can handle countless cycles of boom adjustment without prematurely breaking down. Rope Structure Wire Count Strand Configuration Key Feature Primary Application Focus 8×K26WS 208 Compacted Strands Enhanced flex life, high fatigue resistance Luffing operations, boom hoist systems

- The Protective Benefit of a Plastic Compound Layer: At Aulone, we understand the stresses involved in luffing operations. That’s why many of our ropes, including those specifically designed for luffing applications like the 8×K26WS, feature an integrated plastic compound layer. This layer sits snugly between the rope’s core and its outer strands, acting much like a flexible, stabilizing “corset.” This internal support system not only reinforces the overall structure of the steel wire rope but critically, it also extends its effective service life, especially when operating in demanding or adverse conditions. Furthermore, this protective fill actively works to prevent the ingress of water and abrasive dust. By blocking these contaminants, it effectively stops corrosion from starting within the rope’s core – a common cause of premature failure. An added benefit of this layer is that it cushions the wires, preventing direct metal-to-metal contact between the strands. This direct contact can cause friction and wear, so by eliminating it, we further prevent potential damage and significantly enhance the rope’s durability and lifespan.

Essential Installation and Maintenance Practices for Luffing Ropes

- Sheave Compatibility is Non-Negotiable: The physical dimensions of the sheaves the rope runs over are critically important. We strongly recommend maintaining a ratio of at least 20:1 between the sheave’s diameter and the wire rope’s diameter. This larger sheave diameter distributes the bending stress more evenly across the rope. Equally important is the sheave’s groove diameter. It must be precisely sized to be only 5% to 10% larger than the wire rope’s diameter. If the groove is too large, the rope can develop “flat spots” or be crushed, leading to its rapid degradation. If it’s too small, the rope can be forced into the groove, causing excessive wear and deformation of the wires.

- The Vital Role of Consistent Lubrication: Proper lubrication is absolutely essential for luffing wire ropes. We advise using high-quality, specialized lubricants such as graphite-based or complex lithium-based greases. For luffing wire ropes, it’s especially important to ensure that the lubricant penetrates effectively, particularly in the areas where the rope is constantly bending around the sheaves and drums. This ensures the internal wires are well-protected and can move smoothly against each other, minimizing friction and wear.

What Are the Key Considerations for Ensuring Wire Rope Quality and Compliance?

We need to ensure the wire ropes we choose meet the highest standards. This means looking at their quality and any certifications they might have.

Our products are manufactured with high quality as a priority. We focus on features like high tensile strength and high breaking load. Many of our ropes comply with EN12385-4 standards.

We offer customizable logos for branding. Also, if clients require them, we can provide certificates like BV, CE, RMRS, DNV, and ABS. Our factory has four production lines, which helps us meet diverse needs. We also offer plastic-impregnated and galvanized options.

How Can I Optimize the Selection of Wire Ropes for Different Equipment and Industries?

Selecting the right wire rope depends heavily on the specific equipment and the industry it serves. Different applications have unique demands that require tailored solutions.

We export to many countries like Singapore, Indonesia, Vietnam, Saudi Arabia, UAE, Russia, and Australia. Our customers include purchasing managers, wire rope and sling buyers, distributors, crane rental companies, and mining companies.

Tailoring Solutions for Specific Equipment Needs

In infrastructure and heavy lifting scenarios, crawler cranes play a crucial role. The wire ropes they use, for lifting and for luffing, have distinct selection requirements due to their different functions. This article will explain the key selection points for these two types of wire ropes based on industry standards and practical experience. This will help users accurately match their needs and ensure both operational safety and efficiency.

Conclusion

Selecting the precise wire rope for your crawler crane isn’t just a technical detail; it’s fundamental to ensuring operational safety, maximizing efficiency, and protecting your investment.