Are you frustrated with your crane wire ropes twisting and causing operational headaches? It’s a common problem that can lead to inefficiencies and safety concerns. We understand the challenges you face in maintaining smooth and reliable crane performance.

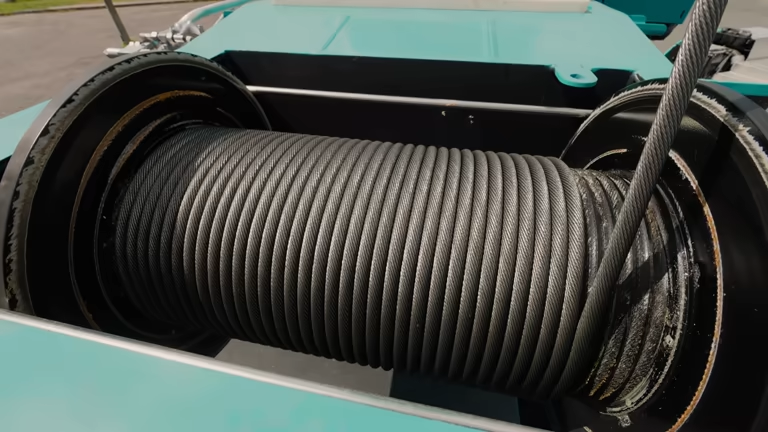

Rotation resistant crane wire ropes offer a robust solution to the common problem of rope twist, significantly improving the stability and safety of your lifting operations.

Imagine a world where your crane works seamlessly, with no annoying twists to slow you down. I want to share how making the right choice in wire rope can change your entire lifting experience.

What Makes Crane Wire Ropes “Rotation Resistant”?

Are you curious about the technology behind these specialized ropes? Understanding their unique construction is key to appreciating their benefits.

Rotation resistant crane wire ropes feature a special construction that counteracts the torque generated during lifting, preventing the rope from untwisting under load.

This specialized design means the rope naturally resists spinning. It’s like having a built-in stabilizer for your load. Think of it as the rope being designed to work “against itself” in a controlled way.

The Core Principle: Layered Strands

At the heart of rotation resistance is how the strands are laid. I’ve seen firsthand how this detail makes a massive difference.

Outer Layer Construction

- Purpose: The outer layers are typically laid in the opposite direction of the inner layers.

- Mechanism: This counter-lay action creates opposing forces that cancel out the torque.

- Benefit: It significantly reduces the tendency for the rope to spin or unlay when a load is applied.

Inner Layer Construction

- Purpose: Inner layers often have a different lay direction or number of wires.

- Mechanism: This internal configuration further contributes to the rope’s stability.

- Benefit: It builds a foundation of strength while maintaining the overall anti-rotation properties.

Beyond Construction: Material Matters

The materials used are just as important as the lay of the strands. High-quality steel is a must.

| Feature | Description | Impact on Rotation Resistance |

|---|---|---|

| High Tensile Strength | The rope’s ability to withstand pulling forces. | Crucial for loads; prevents stretching and deformation. |

| Galvanization | A protective zinc coating applied to the wires. | Resists corrosion and wear, prolonging rope life. |

| Plastic Impregnation | A plastic layer infused within the rope’s core or strands. | Reduces internal friction and increases fatigue life. |

How Does This Impact Your Crane’s Performance?

The difference you’ll see is dramatic. It’s not just about the rope; it’s about the entire operation becoming more efficient and safer.

How Can Rotation Resistant Crane Wire Ropes Improve Lifting Stability?

Do you want to achieve smoother, more controlled lifts every time? The stability these ropes offer is a game-changer.

Rotation resistant crane wire ropes ensure a more stable load during lifting by minimizing unraveling and maintaining a consistent path, leading to greater precision.

This means less sway and more predictable movement of your suspended loads. It translates directly to better control on your job site.

Reducing Load Sway

The inherent tendency of a standard rope to twist can cause loads to sway unpredictably. This can be a major issue when precise placement is required.

- Problem with Standard Ropes: As a load is lifted, the torque can cause the rope to rotate, leading to the load spinning or swinging.

- Solution with Rotation Resistant Ropes: The counter-acting forces in the rope’s construction absorb much of this torque. This keeps the load more stable and directly below the lifting point.

- Practical Benefit: This allows for more accurate positioning of materials, reducing the risk of accidents and increasing productivity.

Maintaining Verticality

Imagine lifting a tall structure or a long girder. Keeping it perfectly vertical is essential.

- Challenge: Without the right rope, the load can drift or tilt as it ascends, requiring constant adjustments.

- Advantage: Rotation resistant ropes help keep the load vertical throughout the lifting process. The rope itself acts as a more rigid suspension point.

- Result: This simplicity in operation means less time spent correcting the load’s position and greater confidence in the lift.

Enhancing Operator Control

A stable load is easier for the crane operator to manage. It’s a direct link between the rope’s properties and the operator’s experience.

- Operator Experience: When the rope twists, operators often have to compensate by adjusting crane movements, which can be counter-intuitive and difficult.

- Positive Impact: With a rotation resistant rope, the load behaves more predictably. The operator can focus on executing the lift smoothly without fighting the rope.

- Safety Implication: This improved control leads to a safer working environment for everyone on the ground.

What are the Key Benefits of Using Rotation Resistant Crane Wire Ropes?

Are you looking for tangible improvements in your daily operations? The advantages go beyond just preventing twists.

Rotation resistant crane wire ropes offer enhanced safety, increased operational efficiency, and longer service life, ultimately reducing downtime and operational costs.

These ropes are an investment that pays off by making your work more reliable and less prone to issues.

Safety First

Safety is always the top priority. These ropes contribute to a safer working environment in several ways.

- Reduced Risk of Load Dropping: By preventing unwanted spinning and maintaining stability, the likelihood of a load shifting or becoming unstable, and potentially dropping, is significantly reduced.

- Minimized Snagging: A rope that maintains its shape is less likely to snag on surrounding structures or the load itself.

- Improved Visibility: A stable load is often easier to see and track, helping ground personnel stay aware of its position during complex lifts.

Certifications and Compliance

Having the right certifications is crucial, especially for international operations. We ensure our ropes meet global standards.

| Certification Type | Description | Relevance to Rotation Resistant Ropes |

|---|---|---|

| BV | Bureau Veritas: A global leader in testing, inspection, and certification services. | Verifies that the ropes meet specific industry standards for quality and performance. |

| CE | Conformité Européenne: Indicates conformity with health, safety, and environmental protection standards. | Ensures the product meets the requirements of member states of the European Economic Area. |

| RMRS | Russian Maritime Register of Shipping: A classification society for ships and marine structures. | Important for maritime applications, ensuring ropes meet stringent safety requirements for marine use. |

| DNV | Det Norske Veritas: A Norwegian foundation providing services in classification, verification, and advise. | Certifies that the ropes are suitable for demanding offshore and marine applications. |

| ABS | American Bureau of Shipping: A maritime classification society. | Guarantees the rope’s compliance with tough offshore and onshore lifting standards. |

Increased Efficiency and Productivity

When your equipment works as it should, your entire project moves faster.

- Faster Setup: Less time spent dealing with rope twists means faster rigging and deployment.

- Reduced Rescheduling: Fewer operational disruptions due to rope issues mean fewer delays and more consistent progress.

- Precise Operations: The ability to place loads accurately speeds up assembly and construction processes.

Longer Service Life and Cost Savings

A durable rope means less frequent replacement, saving you money in the long run.

- Wear and Tear Reduction: The specialized construction and potential galvanization/plastic impregnation protect against wear, increasing the rope’s lifespan.

- Fewer Replacements: A longer service life translates directly into lower capital expenditure on replacement ropes.

- Reduced Maintenance: Optimized performance means less need for interim adjustments or corrective maintenance.

What Types of Cranes Benefit Most from Rotation Resistant Wire Ropes?

Are you wondering if your specific crane setup would see these benefits? Many do!

Cranes that lift heavy, awkward loads or operate in environments with significant torque generation, such as tower cranes, offshore cranes, and material handling cranes, gain the most from rotation resistant wire ropes.

Essentially, any crane where rope twist is a recurring problem will see a significant improvement.

Tower Cranes

These cranes often lift heavy building materials to great heights.

- Challenge: The height and weight involved create substantial torque.

- Benefit: Rotation resistant ropes ensure that the hook and load remain stable as they ascend and descend, crucial for safe construction.

Offshore Cranes

Operating in harsh marine environments with constantly moving vessels and heavy equipment requires ultimate reliability.

- Challenge: Wind, waves, and the movement of ships amplify the forces acting on the wire rope.

- Benefit: The stability provided by rotation resistant ropes is vital for safety and precision in these challenging conditions.

Material Handling and Overhead Cranes

In factories and warehouses, efficiency and safety in repetitive lifting tasks are key.

- Challenge: Frequent lifting and precise placement of goods can lead to rope fatigue and twist over time.

- Benefit: These ropes ensure consistent performance, reduce wear, and maintain a safer working environment for warehouse staff.

Mining Operations

Underground and open-pit mining involve lifting heavy equipment and materials through significant depths.

- Challenge: The immense weights and long lifting distances generate considerable torque.

- Benefit: Rotation resistant ropes provide the strength and stability needed for safe and efficient mining operations.

Conclusion

Upgrade your lifting operations with rotation resistant crane wire ropes for enhanced safety and efficiency.