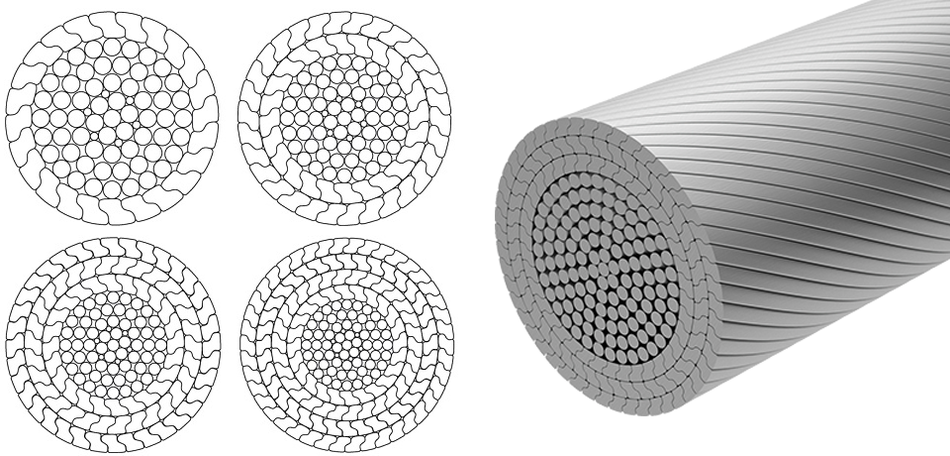

In Full Locked Cables (FLC), the outer layers consist of interlocking Z-shaped wires helically spun around an OSS core, effectively preventing external agents from penetrating into the inner strands. The combination of the FLC’s closed construction design, Galfan-coated (95% Zn / 5% Al) Z-shaped outer wires, and an internal zinc-rich paste blocking compound used by AULONE results in a cable with multi-stage corrosion protection.

The outer Z-shaped wires are generally spun in opposite directions around a central core of round wires. Each individual wire undergoes rigorous testing and verification for tensile strength, ductility, elongation at fracture, bending and torsional properties, and adhesion of zinc coating in accordance with EN 10264 and EN 12385-10.

Key Properties:

Excellent axial stiffness

Optimum strength-to-weight ratio

Outstanding fatigue resistance

Torque-balanced design

Excellent resistance to lateral forces, making it ideal for cable clamping

Four-stage corrosion protection system

AULONE patented anti-vibration surface treatment

This construction ensures that AULONE FLCs deliver high reliability, superior durability, and long service life even under demanding industrial and marine applications.

Kaiyuan road 36,Chunkou,Liuyang, Hunan,China.

info@steelwireropes.cn

admin@steelwireropes.cn

Phone : +86 15573139663

WhatsApp : +86 15573139663

Expert guidance on wire rope specifications and applications

WhatsApp us

Free samples, product catalog, and expert consultation available.