Wire ropes are essential components in lifting, hoisting, and heavy-duty industrial applications. Among the various types of wire ropes, compacted wire ropes are widely recognized for their enhanced strength, durability, and performance. These ropes are specially engineered to meet the rigorous demands of modern industrial operations.

A compacted wire rope is a type of rope in which the individual wires in each strand are mechanically compressed after the rope is formed. This process increases the wire’s cross-sectional density and reduces internal voids, resulting in a rope that is stronger, more durable, and more resistant to wear and fatigue than conventional wire ropes of the same diameter.

Unlike standard wire ropes, where the wires retain their natural circular cross-section, compacted wire ropes have slightly flattened wires, which allows for tighter packing and improved rope performance.

The construction of a compacted wire rope involves several key elements:

Core Type:

Fiber Core (FC): Provides flexibility but has lower strength and abrasion resistance.

Independent Wire Rope Core (IWRC): Enhances strength, stiffness, and resistance to crushing.

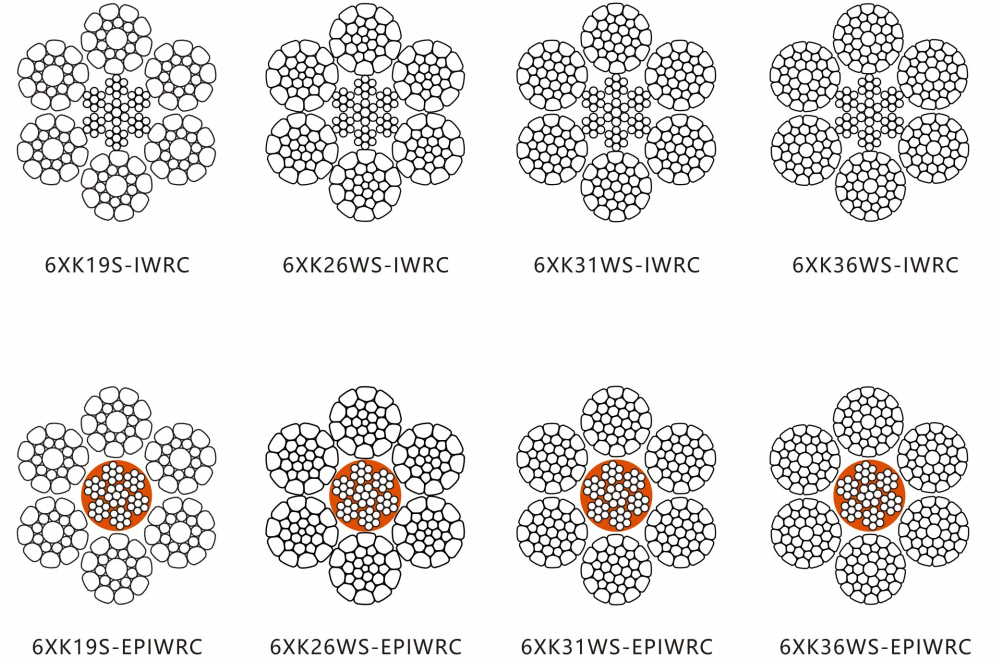

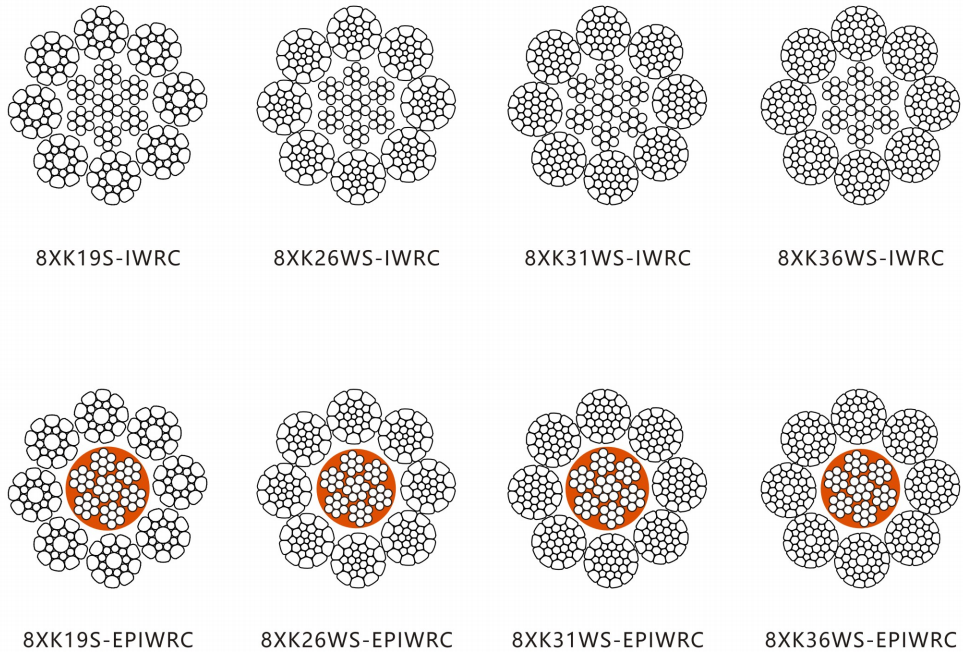

Strand Configuration:

Compacted wire ropes can be manufactured in various strand configurations such as 6×19, 6×36, or 8×19, depending on the application. The compaction process increases the metal content per strand, improving rope strength.

Material:

Carbon Steel: For standard lifting and industrial use.

Galvanized Steel: Provides corrosion resistance for outdoor or marine environments.

Stainless Steel: Used in highly corrosive environments.

Compaction Process:

After the rope is strung, each strand passes through a mechanical compaction device that compresses the wires together. This results in:

Reduced rope diameter

Increased breaking load

Smoother surface, reducing friction with sheaves and pulleys

Optional Coatings:

Lubrication: Improves corrosion resistance and reduces internal friction.

Plastic Coating (Plastic Impregnated / PLASTFILL®): Further protects against dirt, moisture, and wear.

Higher Breaking Strength:

The compaction process increases the cross-sectional metal content, giving a higher tensile strength compared to standard ropes of the same diameter.

Improved Abrasion Resistance:

Flattened wires create a smoother outer surface that resists wear from sheaves, drums, and pulleys.

Reduced Diameter for Same Strength:

Because compacted ropes are denser, a smaller diameter rope can achieve the same or greater strength as a larger conventional rope, which is ideal for tight spaces or existing equipment limitations.

Enhanced Fatigue Resistance:

Reduced internal movement of wires minimizes bending fatigue, extending rope life under repetitive load cycles.

Lower Stretch and Deformation:

Compacted ropes experience less elongation under load, improving operational control and safety in lifting applications.

Better Spooling and Handling:

The compacted structure provides superior dimensional stability, which is especially important in multilayer winding drums.

Compacted wire ropes are widely used in applications requiring high strength, durability, and resistance to wear and fatigue:

Cranes and Hoists: For lifting heavy loads safely with minimal elongation.

Mining Operations: Hoist ropes, draglines, and shaft hoisting where durability under cyclic load is critical.

Elevators: Reduced stretch and high fatigue resistance ensure smooth operation and longevity.

Construction Equipment: Tower cranes, pile drivers, and other machinery that operates under heavy loads.

Marine Applications: Compacted ropes with galvanization or plastic coating are used in mooring and winching.

| Feature | Standard Wire Rope | Compacted Wire Rope |

|---|---|---|

| Wire density | Normal | High |

| Breaking strength | Standard | Higher |

| Abrasion resistance | Standard | Better |

| Diameter | Standard | Slightly smaller |

| Fatigue resistance | Standard | Improved |

| Spooling behavior | Moderate | Excellent |

| Surface smoothness | Normal | Smoother |

Compacted wire rope is often compared with or used alongside other specialized ropes:

Non-Rotating Wire Rope: Minimizes rotation under load for crane and hoist applications.

Swaged Wire Rope: Mechanically compressed along its full length for uniform strength.

Plastic Impregnated Ropes (PLASTFILL®): Provide lubrication and protection for long service life.

Plastic-Coated Wire Ropes: Enhance corrosion resistance and reduce dirt ingress.

Compacted wire ropes are manufactured according to international standards, ensuring quality and performance:

EN 12385 (Europe): Specifies requirements for steel wire ropes, including breaking load, construction, and testing.

ISO 2408: Covers steel wire ropes for general purposes.

API and DIN Standards: Applied in specialized industrial or offshore applications.

Compacted wire rope is a premium solution for demanding lifting, hoisting, and industrial applications. Its increased strength, abrasion resistance, reduced stretch, and improved fatigue life make it an ideal choice for heavy-duty operations. By selecting the correct construction, core type, and coating, users can significantly enhance operational safety, equipment longevity, and overall performance.

Kaiyuan road 36,Chunkou,Liuyang, Hunan,China.

info@steelwireropes.cn

admin@steelwireropes.cn

Phone : +86 15573139663

WhatsApp : +86 15573139663

Expert guidance on wire rope specifications and applications

WhatsApp us

Free samples, product catalog, and expert consultation available.