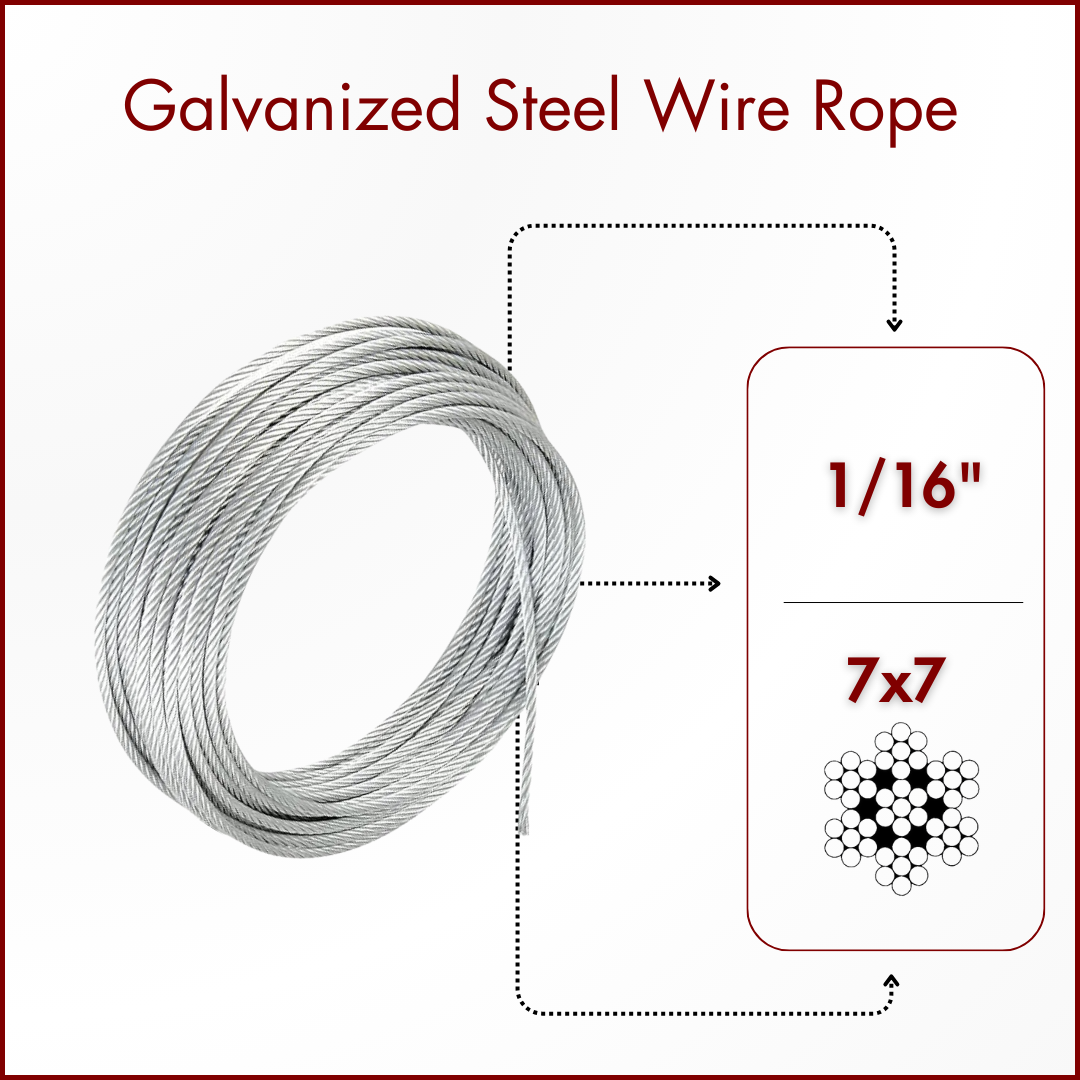

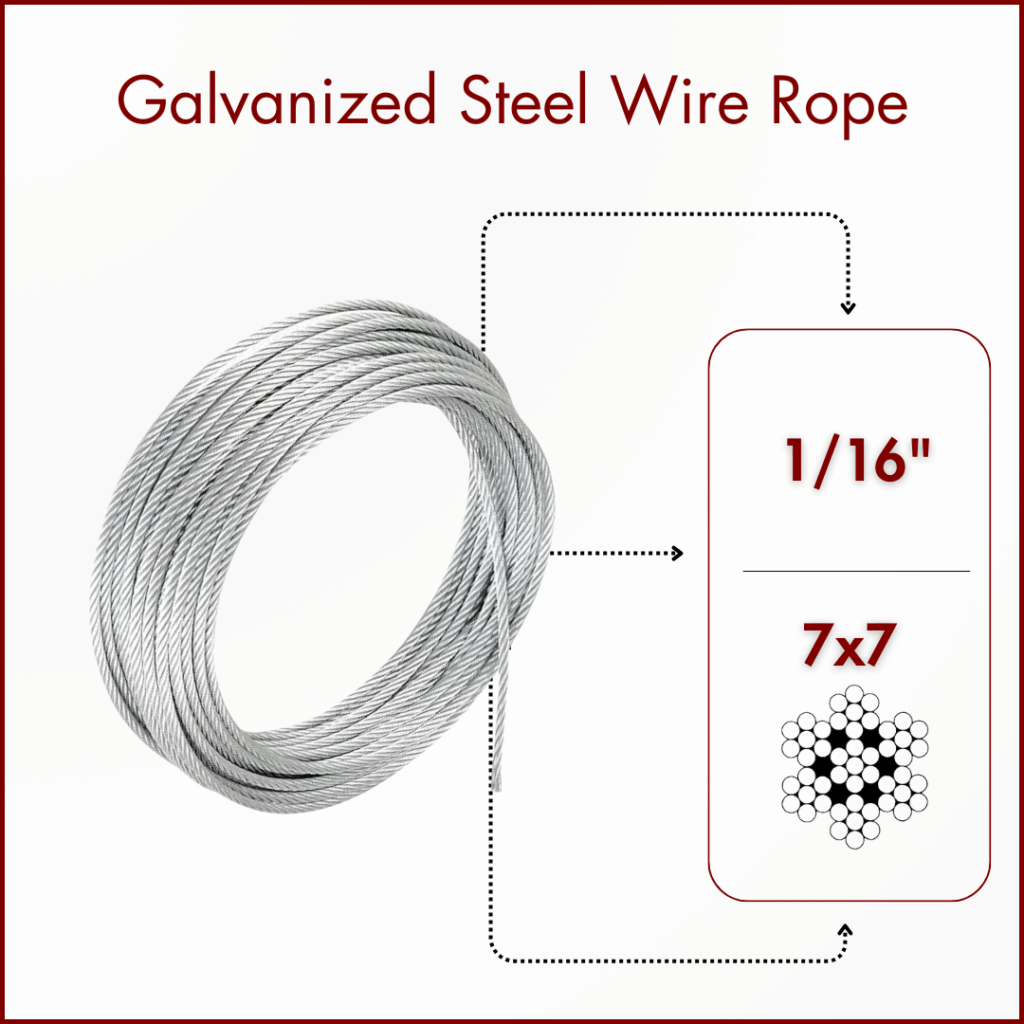

You need to understand wire ropes. But complex terms get in the way. Do you know what “7×7 wire rope” means? Many people find this confusing.

A 7×7 wire rope has 7 strands. Each strand contains 7 individual wires. This design offers flexibility and strength for many uses.

I remember when I first started in this industry. All the numbers and terms felt overwhelming. I quickly learned that understanding these details is key.

How does the 7×7 construction affect wire rope performance?

Understanding 7×7 construction is important. It directly impacts how the rope works. This includes its strength and flexibility.

The 7×7 construction means higher flexibility compared to ropes with fewer wires per strand. It also offers good breaking strength for its size.

When we talk about wire rope, the construction numbers are design codes. “7×7” is a common type. It means one outer layer of 6 strands is laid around a central core strand. Each of these 7 strands is also made of 7 wires laid together. Think of it like a braid within a braid system. This layering affects the rope’s properties.

What are the advantages of 7×7 wire rope?

The 7×7 design offers specific benefits.

- Flexibility: More wires mean the rope bends more easily. This is good for pulleys or tight turns.

- Strength: It still has high tensile strength. It can handle heavy loads.

- Durability: The construction helps distribute stress. This reduces wear on individual wires.

| Feature | Description | Benefit |

|---|---|---|

| Construction | 7 strands, each with 7 wires | Balanced flexibility and strength |

| Applications | Control cables, marine uses, fishing lines | Versatile for many industries |

| Material | Often galvanized or stainless steel | Corrosion resistance for demanding environments |

Where do we use 7×7 wire rope?

This specific construction is very versatile. You find it in many places.

- Aircraft cables: Its flexibility is key for control systems.

- Marine applications: Used for rigging and general purpose lines on boats.

- Industrial uses: Often found in winches or as safety lines.

When my team helps build specialized assemblies, we check the exact wire rope construction needed. A client might need a specific type of flexibility. The 7×7 is often a good fit for these needs.

Is 7×7 wire rope always the best choice?

No, 7×7 wire rope is not always the best. It depends on the job. Different applications have different needs.

The best wire rope type depends on the specific job’s requirements for strength, flexibility, abrasion resistance, and fatigue life.

Every project is unique. For example, some jobs need extreme strength. Others need high flexibility. We always look at the exact need. A crane lifting heavy loads needs a very strong rope. A control cable needs a flexible rope.

What makes other constructions different?

Other constructions offer different properties.

- 6×19 construction: This means 6 strands with 19 wires each. It is stronger and more resistant to abrasion. It is less flexible than 7×7.

- 19×7 construction: This is a rotation-resistant rope. It has a complex design. It is used in cranes where loads might spin. It is more flexible than 6×19.

These differences are critical. Choosing the wrong rope can be costly. It can even be dangerous. We always match the rope to the task.

| Wire Rope Type | Flexibility | Strength | Common Uses |

|---|---|---|---|

| 7×7 | High | Good | Aircraft, marine, control cables |

| 6×19 | Medium | High | Cranes, general hoisting, slings |

| 19×7 | Very High | High^1^ | Non-rotating applications, hoist ropes |

How do we ensure the right choice for our clients?

We work closely with clients like Andri. They have specific needs, like high quality and certifications. We review their project details.

- First, we look at the load requirements. How much weight will the rope lift?

- Second, we check the operating environment. Will it be wet? Hot? Corrosive?

- Third, we consider the expected lifespan. How long does the rope need to last?

For example, for marine uses, we often recommend galvanized or stainless steel 7×7. This is because they resist corrosion. For heavy lifting, we might suggest a 6×19 construction for more strength. Our goal is to provide the best product. We make sure it meets specific standards like EN12385-4. We can provide BV & CE, RMRS, DNV, ABS certificates when needed.

What should you consider when buying wire rope?

When you buy wire rope, many factors matter. Do not just look at the price. Look at the value.

When buying wire rope, you should consider material, breaking load, flexibility, resistance to fatigue, and environmental conditions.

I have seen clients focus only on price. This can lead to problems later. Quality matters more.

What are the key quality indicators?

High-quality wire rope has specific features.

- High tensile strength: This means it can handle heavy pulling forces.

- High breaking load: This is the maximum force it can withstand before breaking.

- Compliance with standards: Ropes should meet international standards, like EN12385-4.

These are not just buzzwords. They are critical safety measures. For example, our ropes often exceed standard breaking loads. This provides an extra layer of safety for our customers.

| Quality Indicator | Importance for Buyers |

|---|---|

| High tensile strength | Ensures rope can withstand operational stress |

| High breaking load | Defines safety margin against failure |

| Material quality | Affects corrosion resistance and overall life |

| Certifications | Guarantees compliance with safety and industry norms |

How do certificates and customization help?

Certificates confirm quality. BV & CE, RMRS, DNV, ABS are important proofs. They show the rope meets strict industry rules. This is very important for clients in the UAE or Australia. They often have high standards. Customization is also a big plus. We can provide plastic impregnation or galvanization. We can also add a custom logo. This helps our partners with their branding.

These details help building trusting relationships. When a client knows they get certified, high-quality products, they come back. I learned from long experience that trust is key in this business.

Conclusion

Understanding “7×7 wire rope” is crucial for proper selection. This construction balances flexibility and strength. Always consider your specific needs. Look for quality, high breaking load, and certifications.