Using the wrong wire rope for your crane is a serious risk. It can lead to equipment damage or dangerous failures. You need to know your rope is right for the job.

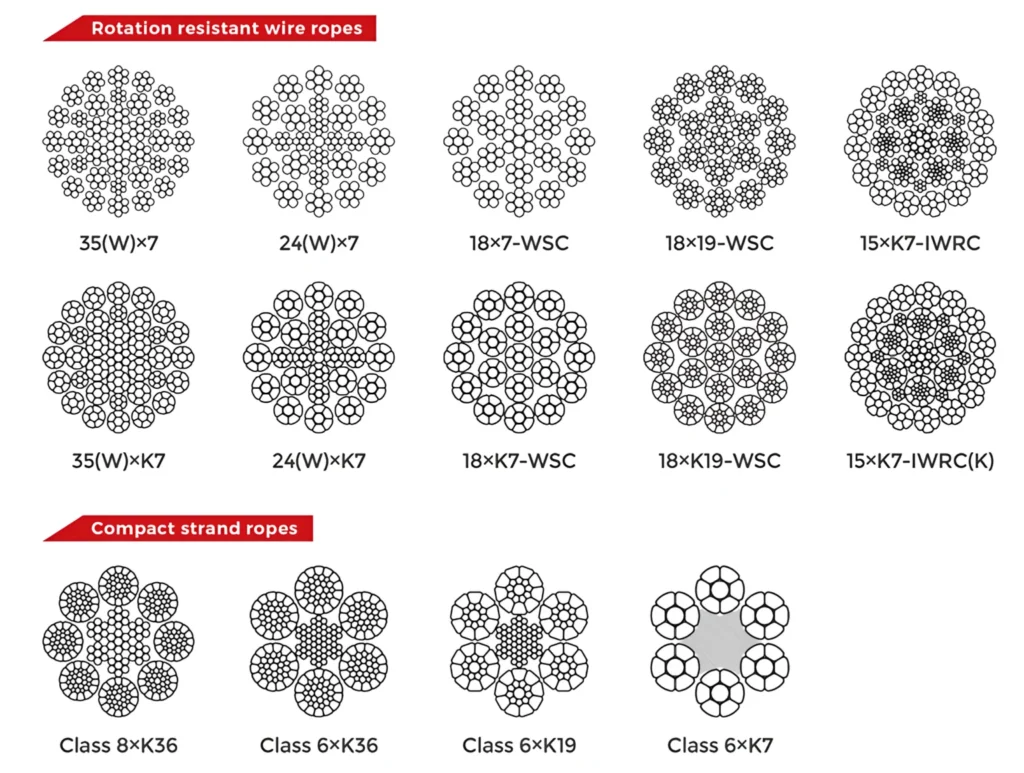

The most common types of wire rope for crane lifting are rotation-resistant ropes and standard 6-strand or 8-strand ropes. The final choice depends on the crane’s reeving system and the specific lifting task.

I remember an early experience where a new customer almost ordered a standard 6-strand rope for a tower crane. That could have been a very costly mistake. This taught me why sharing this knowledge is so important.

How do you choose the right crane wire rope construction?

Choosing a wire rope can seem complicated. There are many codes and types. But it is simple if you break it down. You just need to match the rope’s features to your crane’s job.

You choose the right construction by looking at three main factors: rotation resistance, crushing resistance, and abrasion resistance. Match the rope’s design to the crane’s reeving system, drum, and typical load.

Let’s look deeper at these factors. Each one tells you how the rope will perform under stress. Understanding them helps you make a safer and more cost-effective decision.

Rotation Resistance is Key

Some loads will spin freely on the end of a single line. A standard wire rope will naturally try to un-twist under load. This causes the load to rotate. This is dangerous and unacceptable in most crane operations.

- Standard Ropes (e.g., 6×19, 6×36): These will rotate under load. They are only suitable for applications where both ends of the rope are fixed, or in multi-part reeving systems where the blocks prevent rotation.

- Rotation-Resistant Ropes (e.g., 19×7, 35×7): These are designed specifically to resist twisting. They are constructed with multiple layers of strands. The inner layers and outer layers are wrapped in opposite directions. When the rope is under load, these opposing forces cancel each other out. This keeps the rope, and your load, stable.

| Rope Type | Rotation Behavior | Recommended Use Case |

|---|---|---|

| Standard 6-strand | High rotation | Multi-part reeving, applications where rotation is controlled. |

| Standard 8-strand | Moderate rotation | Multi-part reeving, good for drum spooling. |

| Rotation-Resistant | Low to very low rotation | Single-part hoist lines (tower cranes, mobile cranes). |

Crushing Resistance on the Drum

Your rope must also stand up to pressure on the crane’s drum. This is especially true in multi-layer spooling systems, where the rope winds on top of itself. The pressure from the upper layers can crush and deform the layers underneath.

- Rope Density: Ropes that are more solid and dense resist crushing better. Compaction technology, like

Dyformor similar processes, makes the rope’s surface smoother and the profile more solid. This significantly improves crushing resistance. - Core Support: An Independent Wire Rope Core (

IWRC) provides a solid foundation for the outer strands. It helps the rope keep its round shape and resist flattening under pressure. A softer Fiber Core (FC) offers poor crush resistance.

Abrasion Resistance

Abrasion is the wear and tear a rope experiences from rubbing against sheaves, the drum, and other surfaces.

- Outer Wire Size: Ropes built with fewer, larger outer wires have better abrasion resistance. A rope from the

6x19class, for example, typically has larger outer wires than a rope from the6x36class. - The Trade-off: The downside is that ropes with larger outer wires are less flexible. They do not bend as easily around small sheaves. So, you must balance the need for abrasion resistance with the flexibility requirements of your crane system.

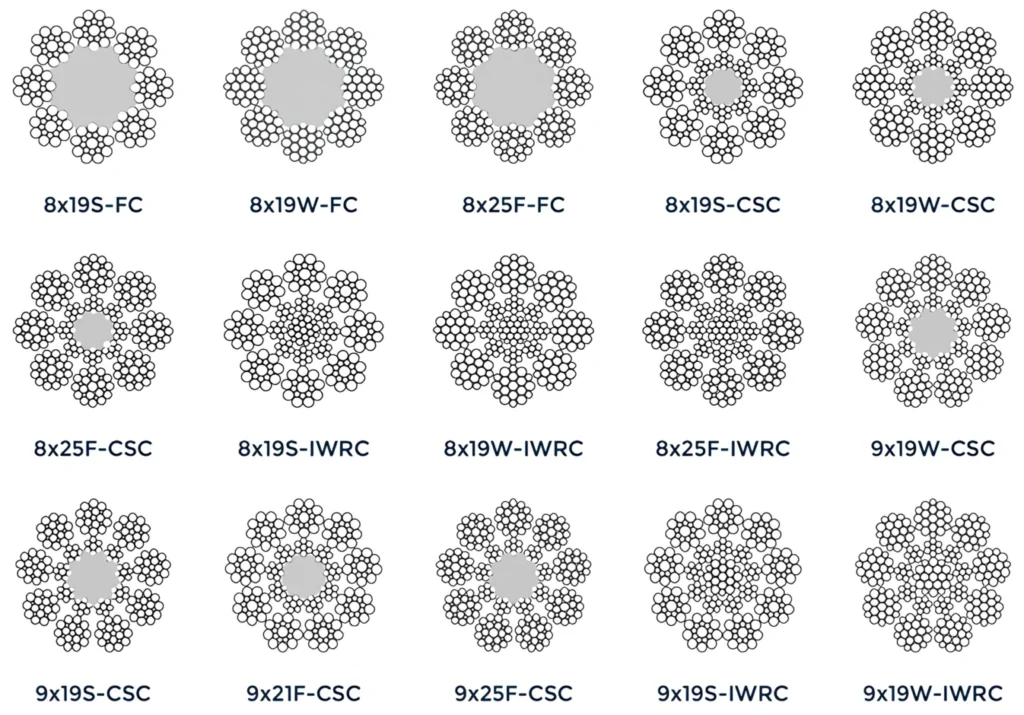

What do wire rope classifications like 6×19 or 8×25 mean?

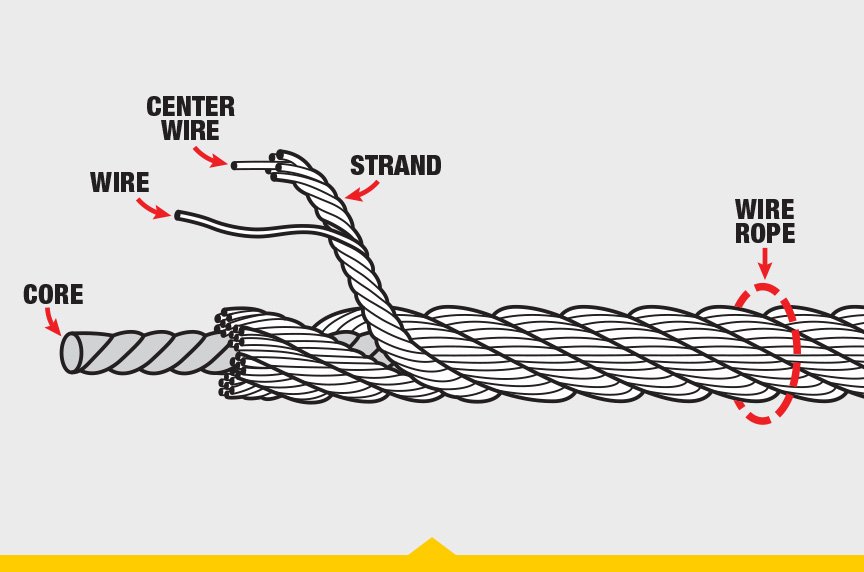

You will see these numbers on every wire rope specification sheet. They are not just model numbers. They are a simple code that describes the rope’s physical construction. Understanding this code is the first step to choosing the right product.

The first number tells you how many strands are wrapped around the core. The second number tells you the nominal quantity of wires in each of those strands. For example, a 6x19 rope has 6 strands, with about 19 wires per strand.

This classification system gives you a quick overview of the rope’s properties. Different combinations of strands and wires result in different levels of flexibility and abrasion resistance.

Breaking Down the Numbers

Let’s make this very clear.

- Strands: These are the main bundles of wire that you can see. They are helically laid around a central core. More strands generally mean more flexibility.

- Wires: These are the individual steel filaments that are twisted together to form a strand. More wires in a strand also increase the rope’s flexibility, but it usually means the wires are smaller and less resistant to abrasion.

So, a rope with many strands, and many wires per strand, will be very flexible. A rope with fewer strands, and fewer wires per strand, will be more rigid but will resist surface wear better.

Common Crane Rope Classifications

Here is a simple table to show how these classifications relate to their use in cranes.

| Classification | Key Characteristics | Typical Crane Application |

|---|---|---|

6x19 Class | Good abrasion resistance, relatively stiff. | General hoisting, boom pendants, where flexibility is not the top priority. |

6x36 Class | Very flexible, good fatigue resistance, lower abrasion resistance. | Main hoist lines that run over multiple sheaves. A very popular choice. |

8x25 Class | More flexible than 6-strand ropes, very stable on drums. | Excellent for multi-layer spooling on crane hoist drums. Resists crushing well. |

19x7 & 35x7 | Rotation resistant. Complex, multi-layer construction. | Main hoist lines for mobile cranes and tower cranes where a single line is used. |

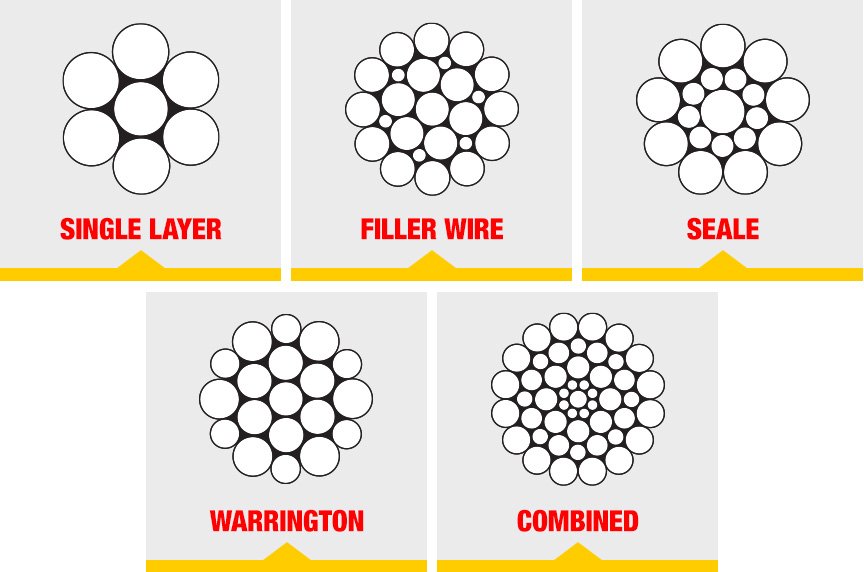

What Do S, FW, and WS Mean?

Sometimes you will see letters after the numbers, like 6x25FW or 6x19S. These refer to the specific arrangement of wires within a strand.

- S (Seale): A strand with a layer of large outer wires over a layer of smaller inner wires. This offers good abrasion resistance.

- FW (Filler Wire): A strand with two same-sized layers of wires, with small “filler” wires in the gaps. This provides good flexibility and crush resistance.

- WS (Warrington Seale): A combination design that mixes different wire sizes to achieve a balance of properties.

You do not need to be an expert in these patterns. But knowing they exist helps you understand that even within the same class, like 6x25, there can be different designs for different purposes.

Why is the wire rope core so important for crane operations?

The core is the very center of the wire rope. It is hidden from view, so it is easy to forget. But the core’s job is critical. It is the foundation for the entire rope. The choice of core can change the rope’s strength, flexibility, and lifespan.

The core’s main jobs are to support the outer strands and to hold lubrication. An Independent Wire Rope Core (IWRC) adds strength and crush resistance, while a Fiber Core (FC) adds flexibility. For most cranes, an IWRC is standard.

Let’s explore the different types of cores and why one is better than another for certain jobs.

Independent Wire Rope Core (IWRC)

This is the most common core type for crane ropes.

- What it is: The IWRC is actually a smaller, separate wire rope that runs down the center of the main rope.

- Strength: It contributes to the rope’s overall strength. A rope with an IWRC is about 7.5% stronger than the same rope with a fiber core.

- Crush Resistance: Because it is made of steel, the IWRC provides firm support for the outer strands. This is very important on a crane drum, where the rope is under high pressure. It helps the rope keep its round shape and prevents it from flattening.

- Heat Resistance: The IWRC is not affected by high temperatures in the way a fiber core is.

Fiber Core (FC)

Fiber cores are made from natural fibers like sisal or synthetic materials like polypropylene.

- Flexibility: Ropes with an FC are more flexible than those with an IWRC. The softer core allows the rope to bend more easily.

- Lubrication: The fiber material can absorb and hold lubricant. This provides a source of internal lubrication for the rope as it works.

- Disadvantages: FC ropes have lower strength and poor crush resistance. They are not recommended for multi-layer spooling. High temperatures can also dry out or damage the core, leading to a loss of support and rope failure. They are rarely used for modern crane main hoist lines.

Plastic Impregnated (PI) Core

This is an advanced feature that we offer. It provides a significant performance boost.

- What it is: Plastic impregnation involves filling the spaces within the rope with a special polymer. This can be done just to the IWRC, or to the entire rope.

- Benefits:

- It locks in factory lubrication. The plastic seals the lubricant inside the rope, ensuring it stays where it is needed most.

- It prevents internal corrosion. The plastic layer acts as a barrier, stopping moisture and dirt from getting into the core of the rope.

- It increases stability. The plastic fills all the empty spaces, creating a more solid and stable rope structure. This reduces internal friction between strands and wires.

- It extends fatigue life. By reducing internal friction and wear, a plastic impregnated rope will last longer in demanding applications.

What are the most important safety standards for crane wire ropes?

In our factory, we know that standards equal safety. Adhering to international standards is not a choice; it is a requirement. For a buyer, seeing a standard like EN 12385-4 on a certificate is your guarantee that the rope meets strict quality and safety rules.

The most important standard for crane ropes is EN 12385-4. This European standard specifies the safety requirements for steel wire ropes used on cranes. Other key standards include ISO 4309 for inspection and discard, and API 9A for offshore use.

Buying a rope without proper certification is a big risk. Let’s look at why these standards matter so much for your business and the safety of your operators.

Understanding EN 12385-4

This is the main standard to look for when buying crane ropes.

- What it Covers: This document details the specific requirements for materials, manufacturing, dimensions, and testing. It sets the minimum breaking force a rope must have based on its size and construction.

- Why It Matters: Compliance with

EN 12385-4means the rope has been produced and tested to a high, internationally recognized level. It gives you confidence in the rope’s stated breaking load and its overall quality. As a manufacturer, this is the standard our production lines are built to meet.

The Role of Third-Party Certification

A manufacturer’s declaration is good, but an independent certificate is better. Many projects require it. That is why we can provide certification from various third-party agencies if a client needs it. This confirms our ropes meet the highest standards.

I have had many conversations with clients who need this for their projects. They need to show their own customers and safety inspectors that they use only certified materials.

| Certification Body | Primary Focus | Why It Is Important to a Buyer |

|---|---|---|

| DNV, ABS | Marine & Offshore Industries | Guarantees the rope is suitable for the harsh, corrosive saltwater environment of ships and oil rigs. |

| RMRS | Russian Maritime Register of Shipping | Often a mandatory requirement for any equipment being used on Russian-flagged vessels or projects in Russia. |

| BV (Bureau Veritas) | General Industry, Marine, Construction | A globally recognized mark of quality and conformity for many types of equipment, including wire rope. |

| CE Marking | Products sold in the European Economic Area | Shows the product meets EU safety, health, and environmental protection requirements. |

When you request a rope with one of these certificates, you are asking for an extra layer of proof. It shows that an independent inspector has reviewed the product and its documentation and has confirmed its quality.

When should you replace a crane wire rope?

Every wire rope is a consumable item. It wears out over time. It is important to know when to take it out of service. Replacing a rope too soon is wasteful. But waiting too long can lead to a sudden, dangerous failure.

You should replace a crane wire rope when inspection reveals damage that exceeds the limits set in the ISO 4309 standard. This includes a certain number of broken wires, significant loss of diameter, kinking, birdcaging, or heavy corrosion.

Regular and competent inspection is the most important thing you can do to ensure crane safety. Let’s look at the main signs that a rope is at the end of its life.

Counting Broken Wires

This is the most common reason for retiring a rope.

- How to Count: Inspectors look for broken wires over a set length of the rope. This length is usually defined by the rope’s diameter, for example, over a length of “6d” (6 times the rope diameter) or “30d”.

- Discard Criteria: The

ISO 4309standard provides tables that tell you the maximum number of allowable broken wires for different types of ropes and applications. Once the number of breaks in one section reaches this limit, the rope must be discarded. Broken wires concentrated in one area are particularly dangerous.

Measuring Rope Diameter

A reduction in the rope’s diameter is a serious warning sign.

- Why it Happens: Diameter loss can be caused by external abrasion, where the outer wires are worn down. It can also be caused by internal wear or corrosion, or the collapse of the rope’s core.

- How to Measure: Always measure the rope across its widest points (the crown of the strands), not in the valleys. Use proper calipers.

- Discard Criteria: A general rule is to consider replacement when the rope has lost more than 7% of its nominal diameter. A loss of diameter due to core failure is a cause for immediate removal from service.

Identifying Deformations

Deformations are visible distortions in the rope’s structure. They are almost always a reason to discard the rope immediately because they create an imbalance in how the load is shared by the strands.

| Deformation | Description | Common Cause | Recommended Action |

|---|---|---|---|

| Kinking | A sharp, permanent bend in the rope where the strands are damaged. | Improper unreeling or pulling a loop tight. | Immediate discard. |

| Birdcaging | The outer strands bulge outwards from the core. | Sudden release of load (shock loading) or a problem with the spooling. | Immediate discard. |

| Crushing | The rope body is flattened and distorted. | Excessive pressure on the crane drum, especially with multi-layer spooling. | Monitor closely; discard if severe. |

| Core Protrusion | The rope’s core pushes out from between the outer strands. | Can be caused by shock loading or improper installation. | Immediate discard. |

Regular, documented inspections are not just a good idea; they are required by law in most places. Make sure the person inspecting your ropes is trained and understands these discard criteria.

Conclusion

Choosing the right crane rope means matching its design to the job. Pay attention to construction, core, and standards. And always perform regular inspections for safety.