Are you confused by wire rope specifications like 35×7? Choosing the wrong rope can lead to equipment damage or safety hazards. I am here to help you understand it.

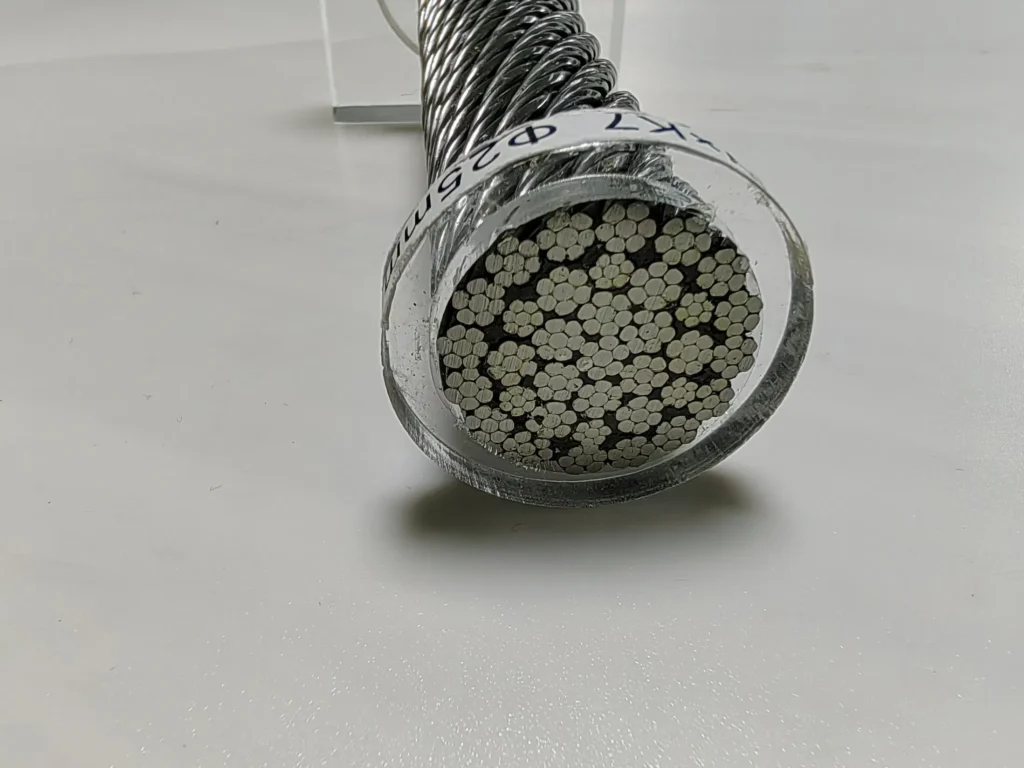

In simple terms, 35×7 means the wire rope is constructed from 35 strands, with each strand composed of 7 individual wires. This specific design makes it highly flexible and resistant to rotation, a key feature for crane operations.

I remember seeing these codes for the first time. They looked like a secret language. But once I understood the logic, picking the right rope became simple. Let’s break this code down together.

Why Is 35×7 Construction Considered Rotation-Resistant?

Have you ever seen a heavy load start spinning at the end of a crane line? The 35×7 rope design is the solution to stop that from happening.

Its rotation-resistance comes from having multiple layers of strands. These layers are wound in opposite directions. The turning force of the inner layers cancels out the turning force of the outer layers. This keeps the rope stable.

To dive deeper, we need to understand a basic concept in wire rope: lay direction. Strands in a wire rope can be twisted to the right (right lay) or to the left (left lay). A standard rope has all its strands going in the same direction. This creates torque, or a turning force, when a load is applied. For many applications, this is not a problem. But for a single hoist line lifting a load high in the air, that torque can cause the load to spin out of control.

The Mechanics of Torque Balance

A 35×7 rope is a special type of rope called “non-rotating” or, more accurately, “rotation-resistant.” It is built with a clever design to fight its own torque.

Imagine the rope has a core and several layers of strands wrapped around it.

- The inner layers of strands might be twisted to the left (left lay).

- The outer layers of strands are then twisted to the right (right lay).

When you lift a load, both layers want to untwist. But because they are twisted in opposite directions, their forces push against each other. The result is a rope that remains much more stable. The load is less likely to spin.

How This Applies in the Real World

This stability is most important in “single-fall” rigging. This is where a single line of rope runs from the crane to the load. Without a rotation-resistant rope like 35×7, the block and load could spin, making it impossible to position the load accurately and creating a serious safety risk. The 35×7 construction provides the balance needed for these precise and demanding jobs. Think of it as a finely tuned machine, where every component works against another to create perfect equilibrium.

Here is a simplified look at the layers:

| Rope Layer | Typical Lay Direction | Resulting Torque |

|---|---|---|

| Inner Strands | Left Lay | Clockwise Torque |

| Outer Strands | Right Lay | Counter-Clockwise Torque |

| Total Rope | Balanced | Minimal to Zero Net Torque |

What Are the Main Applications for 35×7 Wire Rope?

So, where is this special rope most useful? Its unique properties make it the top choice for very specific jobs where safety and stability are the highest priorities.

A 35×7 wire rope is mainly used as the primary hoist line on mobile cranes, tower cranes, and overhead cranes. Its ability to resist rotation is essential for lifting operations that use a single, unguided rope line.

The “no-spin” characteristic is not just a nice feature; it is often a requirement. Let’s look at the specific machines and situations where I see 35×7 rope used most often.

Tower Cranes in Construction

Think of the giant tower cranes building skyscrapers in a city. The hoist rope has to travel hundreds of feet into the air. Over such a long distance, even a small amount of rope torque would cause the load to spin many times. This would be incredibly dangerous for the workers below and would make it impossible to place steel beams or concrete panels precisely. The 35×7 rope ensures the load goes straight up and straight down.

Mobile and Crawler Cranes

These cranes are the workhorses of many industries, from construction sites to industrial yards. They often use a single line to lift various loads. Whether it is lifting a delicate HVAC unit onto a roof or moving heavy equipment, preventing the load from spinning is crucial for control and safety. The 35×7’s flexibility and rotation resistance make it an ideal main hoist line for these versatile cranes.

Other Specialized Hoisting Uses

You will also find 35×7 ropes in other hoisting scenarios.

- Overhead Gantry Cranes: In factories and shipyards, these cranes move heavy materials along a fixed path. A stable rope prevents damage to the product and surrounding equipment.

- Offshore and Port Cranes: When loading and unloading ships, the environment can be windy and unpredictable. A rotation-resistant rope gives the crane operator better control over the cargo.

Here’s a quick summary of where you’ll find it.

| Application Area | Why 35×7 is Used |

|---|---|

| Tower Crane Hoist | Prevents block and load rotation over very long lifting distances. |

| Mobile Crane Main Line | Provides stability and control for single-fall lifts on job sites. |

| Overhead Factory Crane | Safely handles and positions heavy or sensitive materials. |

| Port and Marine Cranes | Offers superior control when loading and unloading cargo vessels. |

How Does 35×7 Compare to Other Common Wire Rope Constructions?

The 35×7 rope is a specialist. But how does it compare to other common rope types you might encounter, like 19×7 or the standard 6×36?

Compared to 19×7, a 35×7 rope has more strands, making it more flexible and even more rotation-resistant. But, it is often less resistant to crushing on the drum. Against a standard 6×36 rope, 35×7 is far superior in rotation resistance but less durable against abrasion.

Choosing a wire rope is about trade-offs. What you gain in one feature, you might lose in another. I’ve had many clients ask about these differences, so let’s break them down clearly.

35×7 vs. 19×7

Both 35×7 and 19×7 are in the rotation-resistant category. They are built using the same principle of opposing lay directions.

- Rotation Resistance: A 35×7 rope has more outer strands and more layers than a 19×7. This multi-layer construction gives it superior resistance to torque. It is one of the most stable ropes available.

- Flexibility: With 35 strands, the 35×7 rope is more flexible than the 19×7. This allows it to bend around sheaves and drums more easily, which can reduce fatigue and extend its life.

- Crushing Resistance: This is where 19×7 can have an advantage. The larger outer strands of a 19×7 rope can make it more resistant to being flattened or crushed when spooled under high tension on a drum.

35×7 vs. Standard Ropes (like 6×19 or 6×36)

This is a comparison between a specialist and a generalist. Ropes in the 6×19 and 6×36 classes are the most common types of wire rope in the world.

- Rotation Resistance: There is no comparison here. A 6×36 rope will spin aggressively under load. It should never be used in a single-fall lifting application where the load is free to rotate.

- Abrasion and Crushing Resistance: Standard 6-strand ropes usually have larger outer wires. This gives them excellent durability against wear and tear (abrasion) and a high resistance to crushing on a drum. They are tough and built for general work.

- Application: You use 6-strand ropes for jobs where rotation is not an issue, or where the rope is part of a system that prevents rotation (like a multi-part reeving system or a simple pulling application).

Here is a comparison table to make it clearer.

| Feature | 35×7 (Specialist) | 19×7 (Specialist) | 6×36 (Generalist) |

|---|---|---|---|

| Rotation Resistance | Excellent | Very Good | Poor |

| Flexibility | Excellent | Very Good | Good |

| Crushing Resistance | Fair | Good | Excellent |

| Abrasion Resistance | Good | Good | Very Good |

| Best For | Single-line crane hoisting | Single-line crane hoisting | General-purpose rigging, pulling |

What Factors Should You Consider When Choosing a 35×7 Wire Rope?

You know what 35×7 means and where to use it. Now, how do you order the correct one? Choosing the right rope is a critical decision that impacts safety and longevity.

You must check the rope’s diameter, minimum breaking load (MBL), and finish (like galvanized or plastic impregnated). Most importantly, always follow the crane manufacturer’s specifications and required certifications for your industry.

I always walk my clients through a checklist to ensure they get exactly what they need. Price is a factor, but safety and suitability come first. Here are the key points to consider.

Minimum Breaking Load (MBL) and Safety Factor

This is the single most important safety metric.

- MBL: This is the force at which a new rope will break when pulled in a straight line. It is determined by a destructive test in a lab.

- Safety Factor: You never use a rope close to its MBL. A “Safety Factor” is applied to determine the Safe Working Load (SWL). For hoisting people, the factor might be 10:1. For lifting goods, it is often 5:1.

$$ \text{Safe Working Load (SWL)} = \frac{\text{Minimum Breaking Load (MBL)}}{\text{Safety Factor}} $$

You must ensure the rope’s MBL is high enough to handle your heaviest lift, with the correct safety factor applied.

Rope Finish: Bright, Galvanized, or Plastic Impregnated?

The environment where the rope will be used determines the best finish.

| Finish Type | Description | Best Use Case |

|---|---|---|

| Bright (Uncoated) | Plain steel with a lubricant finish. | Dry, indoor environments where cost is a major factor. |

| Galvanized | Steel wires are coated with a layer of zinc. | Outdoor use, humid climates, or marine environments for corrosion protection. |

| Plastic Impregnated | Plastic fills the spaces between the strands and wires. | Harsh environments. The plastic locks in lubricant, prevents internal friction, and keeps out dirt and moisture. It greatly extends the rope’s fatigue life. |

As a manufacturer, we can provide all these finishes. A plastic impregnated core inside a 35×7 rope, for example, creates a very durable and stable rope for demanding tower crane applications.

Certifications and Standards

A wire rope is a piece of engineered safety equipment. It must meet industry standards.

- Manufacturing Standard: Check that the rope conforms to a recognized international standard, such as

EN12385-4, which is a European standard for steel wire ropes on cranes. - Third-Party Certificates: For critical applications like offshore or marine, you may need a certificate from a classification society. These organizations witness the testing of the rope to ensure it meets their strict rules. As a supplier, we can arrange for certificates from bodies like

ABS,DNV, orRMRSif a client requires them for their project. Always confirm what certifications are mandatory for your job.

How Do You Properly Inspect a 35×7 Wire Rope for Safety?

A wire rope is a working part that wears out over time. Proper, regular inspection is not optional. It is a fundamental part of a safe lifting program.

Visually and physically inspect the rope for any broken wires, corrosion, heavy wear (abrasion), and physical damage like kinks or birdcaging. You must follow a regular inspection schedule and retire the rope when it meets defined damage criteria.

I tell my customers that the day a rope is installed is the beginning of the end of its life. How long it lasts depends on use and inspection. A “competent person” must be trained to identify these hazards.

Counting Broken Wires

Individual wires will break through normal fatigue. The key is knowing how many are too many. Retirement criteria are typically based on the number of broken wires found in a specific length of rope (e.g., in a length equal to 6 or 30 times the rope diameter). The crane manual or relevant safety standard (like ASME B30.5) will provide the exact criteria for removal from service.

Checking for a Reduction in Diameter

A loss of rope diameter is a warning sign. It can mean the inner core has failed, or there is excessive external wear. Use proper calipers to measure the rope diameter across its widest points (crown to crown). A significant reduction, often as little as 5-7%, may be cause for retirement.

Recognizing Common Types of Severe Damage

Some damage types require immediate removal of the rope, regardless of other factors.

| Damage Type | Visual Appearance | Cause & Consequence |

|---|---|---|

| Kink | A sharp, permanent bend or loop in the rope. | Caused by pulling a loop tight. The strands and wires are permanently damaged and weakened. |

| Birdcage | The outer strands flare open and form a cage shape. | Usually caused by sudden unloading or improper installation (allowing the rope to untwist). The rope structure is compromised. |

| Core Protrusion | The rope’s inner core pokes out between the outer strands. | Imbalance in the rope structure, often seen in rotation-resistant ropes if handled improperly. The rope is unstable. |

| Heat Damage | Discoloration of the wires (often blue or straw-colored). | Exposure to high heat, such as from welding slag or an engine exhaust. The steel’s temper and strength are lost. |

A daily visual inspection should be performed by the operator. A more thorough, documented inspection should be done periodically by a qualified person. Keeping a log of inspections is a best practice and often a legal requirement.

Conclusion

Understanding 35×7 wire rope is about knowing its structure, its purpose, and its limits. It is a specialized tool for ensuring safety and precision in critical lifting operations.