Are your standard ropes failing under heavy loads? This constant wear and tear risks safety and causes expensive downtime. 35×7 compacted wire rope offers a durable, high-strength solution.

A 35×7 compacted wire rope is a top choice because of its high breaking strength, excellent flexibility, and superior crush resistance. Its unique multi-strand construction provides a stable structure, making it perfect for demanding lifting operations.

I remember a client who constantly replaced their crane ropes. The costs were huge. Then, we introduced them to the 35×7 compacted rope. The change was immediate. Let’s explore why this rope is so different.

How Does its 35×7 Construction Provide Superior Performance?

The numbers “35×7” are not just random. They define the rope’s core strength and special features. Let’s break down what this specific construction means for your daily operations.

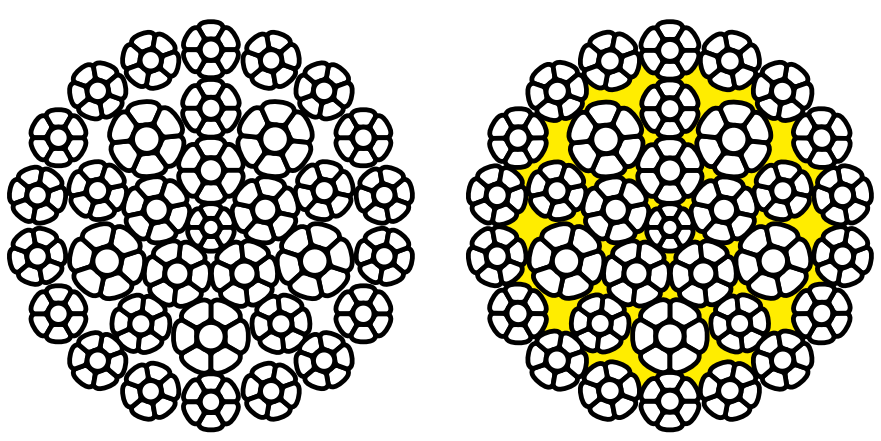

The 35×7 construction consists of 35 strands, each with 7 wires. This multi-strand design, usually with an independent wire rope core (IWRC), gives it excellent flexibility and strong resistance to rotation, ensuring stable performance.

The Power of Multi-Strand Design

A standard wire rope might have 6 or 8 outer strands. A 35×7 rope is different. It is built with multiple layers of strands wrapped around a central core. This complex construction gives it special properties. The large number of strands makes the rope incredibly flexible. It can bend over sheaves and drums with less stress. This reduces metal fatigue and extends the rope’s working life. I have seen our 35×7 ropes outlast conventional ropes by a significant margin in high-cycle applications.

Understanding Rotation Resistance

Rotation resistance is a critical feature. When you lift a load with a single rope line, a standard rope tends to twist or spin. The 35×7 construction is designed to fight this. The outer layer of strands is wrapped in the opposite direction of the inner layers. When the rope is under load, these opposing forces cancel each other out. This keeps the load stable and prevents dangerous spinning. It’s a feature my clients in the high-rise construction business absolutely depend on.

Comparing 35×7 to Other Common Ropes

It’s helpful to see how 35×7 stacks up against more traditional constructions. Each design has its place, but for specific jobs, the 35×7 is clearly superior.

| Feature | 6×36 Class Rope | 35×7 Compacted Rope | Advantage of 35×7 |

|---|---|---|---|

| Rotation | Prone to rotation | Highly resistant | Safer for single-line lifting |

| Flexibility | Good | Excellent | Longer life on small drums |

| Crush Resistance | Moderate | Very Good (when compacted) | Better performance on multi-layer drums |

| Breaking Strength | Good | Excellent (when compacted) | Lifts heavier loads for same diameter |

This table shows the clear engineering advantages. The 35×7 is not just a rope; it is a specialized tool for challenging lifts.

Why is Compaction So Important in This Type of Rope?

You see “compacted” in the name, but what does it really mean? This single manufacturing step dramatically changes the rope’s capabilities and performance. Let’s find out how.

Compaction is a process that flattens the outer strands using rollers or dies. This increases the steel content, smooths the rope’s surface, and locks the components together. It results in higher breaking strength and better wear resistance.

More Steel, More Strength

The compaction process reshapes the round strands into a flatter profile. This process eliminates the gaps that normally exist between the strands. As a result, we can fit more steel into the same diameter. More steel directly translates to a higher breaking load. For a client in Canada, this meant they could use a smaller diameter 35×7 compacted rope for a job that previously required a thicker, heavier standard rope. This made handling easier and put less strain on their crane.

A Smoother Surface for Less Wear

A standard rope has a coarse surface. The individual round wires create high-pressure points where the rope touches sheaves and drums. This causes friction and accelerates wear on both the rope and the equipment. A compacted rope has a much smoother, almost flat outer surface. This spreads the load over a larger contact area. The result is significantly less wear on your expensive sheaves and drums. A long-term customer in the UAE noted that their sheave maintenance costs dropped noticeably after switching to our compacted ropes.

Superior Crush Resistance

When a rope is wound onto a drum in multiple layers, the upper layers can put immense pressure on the lower ones. This can crush and deform a standard rope, damaging its structure and reducing its strength. The compacted strands of a 35×7 rope have a solid, flat profile. They fit together tightly, providing excellent structural support. This makes the rope highly resistant to crushing, which is essential for cranes that use multi-layer hoisting drums.

| Feature | Standard (Non-Compacted) Rope | Compacted Rope | Key Benefit |

|---|---|---|---|

| Surface Profile | Bumpy, round strands | Smooth, flat strands | Reduced wear on equipment |

| Steel Area | Standard | Increased by 10-15% | Higher breaking strength |

| Inter-strand Gaps | Present | Minimized or eliminated | Better crush resistance |

| Durability | Good | Excellent | Longer service life |

What are the Ideal Applications for 35×7 Compacted Wire Rope?

A great tool is only great in the right job. So where does the 35×7 compacted rope truly excel? Let’s look at its best applications and why it’s the professional’s choice.

This rope is ideal for main and auxiliary hoist lines on tower cranes, mobile cranes, and overhead cranes. Its high strength and stability also make it a top performer for demanding mining and piling rig applications.

Tower and Mobile Cranes

In modern construction, cranes are lifting heavier loads to greater heights than ever before. This is where the 35×7 rope shines.

- High Lifting Heights: The rotation-resistant design is critical when the hook is hundreds of feet in the air. It prevents the load from spinning out of control.

- High Strength: Its superior breaking load allows for lifting heavy pre-fabricated modules, increasing construction speed.

I’ve supplied many projects in rapidly growing cities like Singapore and Dubai. The feedback is always the same: the 35×7 rope provides the stability and confidence they need to work efficiently and safely at extreme heights.

Mining and Shaft Hoisting

The mining environment is one of the toughest for any equipment. Ropes are subjected to heavy loads, deep shafts, abrasive materials, and constant use.

- Durability: The compacted design resists the abrasive wear from rock dust and the crushing pressure on multi-layer drums found in mine winders.

- Fatigue Resistance: The rope’s flexibility allows it to handle the repetitive bending of daily hoisting cycles without failing prematurely.

We export to major mining regions like Australia and Russia, where equipment reliability is directly linked to productivity and safety. The 35×7 has proven itself in these harsh conditions.

Piling Rigs and Foundation Work

Foundation work involves intense, dynamic loads. A piling rig’s hammer and extraction cycles put immense stress on the wire rope.

- Crush Resistance: The rope must withstand the shock loads and the pressure of being wound on the drum under high tension. The solid structure of a compacted 35×7 rope is perfect for this.

- Stability: The rope’s stability ensures precise control over the piling equipment, which is essential for accurate foundation work.

How Do You Properly Inspect and Maintain a 35×7 Wire Rope?

Even the toughest rope needs care. Proper inspection and maintenance are not just about following rules. They are about ensuring crew safety and maximizing the return on your investment.

Regularly inspect for broken wires, corrosion, diameter reduction, and structural damage. Keep the rope properly lubricated to prevent internal friction and rust. Follow a strict schedule and keep detailed records of all inspections.

Your Daily Visual Inspection

Before every shift, a qualified person should perform a visual check of the rope. It only takes a few minutes, but it can prevent a catastrophic failure.

A Deeper Look: Periodic Inspections

A more thorough inspection must be done on a regular schedule. This involves cleaning a section of the rope and carefully examining its condition.

Key Things to Look For

- Broken Wires: Note the number and location of any broken wires. Too many broken wires in one area is a clear sign the rope needs to be retired.

- Diameter Reduction: Use a caliper to measure the rope’s diameter. A significant decrease suggests internal core damage or excessive external wear.

- Corrosion: Look for rust, especially pitting. External rust is bad, but internal rust is worse as it can hide the true condition of the rope.

- Deformation: Check for any kinks, bird-caging, core protrusions, or areas that have been crushed flat. Any deformation compromises the rope’s strength.

I once visited a client who was having issues with rope life. During an inspection, we found their lubrication schedule was inadequate. The ropes looked fine on the outside, but they were corroding from the inside out. We helped them implement a proper lubrication plan, and their rope replacement frequency dropped by half.

Retirement Criteria Table

Standards like EN12385-4 provide clear guidelines for when a rope is no longer safe to use. You should never use a rope beyond these limits.

| Criteria | Retirement Guideline | Why It’s Critical |

|---|---|---|

| Broken Wires | Exceeding a set number in a specific length | Indicates the rope is losing strength due to fatigue. |

| Diameter Reduction | More than 7% loss from nominal diameter | Suggests core failure or severe external wear. |

| Corrosion | Visible pitting or signs of internal corrosion | Rust weakens the steel and can lead to sudden failure. |

| Deformation | Kinks, bird-cages, or severe crushing | The rope’s structure is compromised and it cannot handle its rated load. |

What Certifications Assure the Quality of a 35×7 Rope?

Not all wire ropes are created equal. Certifications are your guarantee of quality, safety, and traceability. They prove that the rope you are buying meets strict international standards.

Always demand a manufacturer’s test certificate that confirms compliance with a known standard like EN12385-4. For specific industries, third-party certifications from bodies like DNV, ABS, or RMRS are crucial for verification.

The Manufacturer’s Mill Certificate

This is the most fundamental document. It is the rope’s birth certificate. At our factory, every single rope we produce comes with a detailed test certificate. You should never accept a rope without one. It must include:

- Rope Details: The exact construction (e.g., 35×7 IWRC), diameter, and tensile strength (e.g., 1960 N/mm²).

- Breaking Load: The actual breaking load from a destructive test of a sample from that production batch.

- Standard Compliance: A clear statement that the rope conforms to a specific standard, such as EN12385-4.

- Traceability: A unique serial number that allows you to trace the rope back to its manufacturing date and raw materials.

Why Third-Party Certifications Matter

While a mill certificate is essential, third-party certification provides an extra layer of trust. These independent bodies audit our factory, witness our testing, and verify our quality control processes.

DNVorABS: These are often required for equipment used in the marine and offshore industries. They have extremely strict requirements because the operating environment is so unforgiving.RMRS: This is the Russian Maritime Register of Shipping. If you are supplying a project in Russia, this certification is often mandatory.- CE MARKING: This indicates conformity with health, safety, and environmental protection standards for products sold within the European Economic Area.

A purchasing manager from an Indonesian offshore company once told me, “Your DNV certificate is what allows me to sleep at night.” He knew that the certification represented a promise of quality that was verified by a trusted global expert. It removes doubt and ensures compliance with the highest safety standards.

Conclusion

The 35×7 compacted wire rope offers superior strength, rotation resistance, and durability for heavy lifting. Always choose a fully certified product and maintain it correctly for maximum safety and performance.