Are your standard wire ropes wearing out too fast? This frequent replacement can cost a lot of time and money. A compacted wire rope might be the exact solution you need for a longer service life.

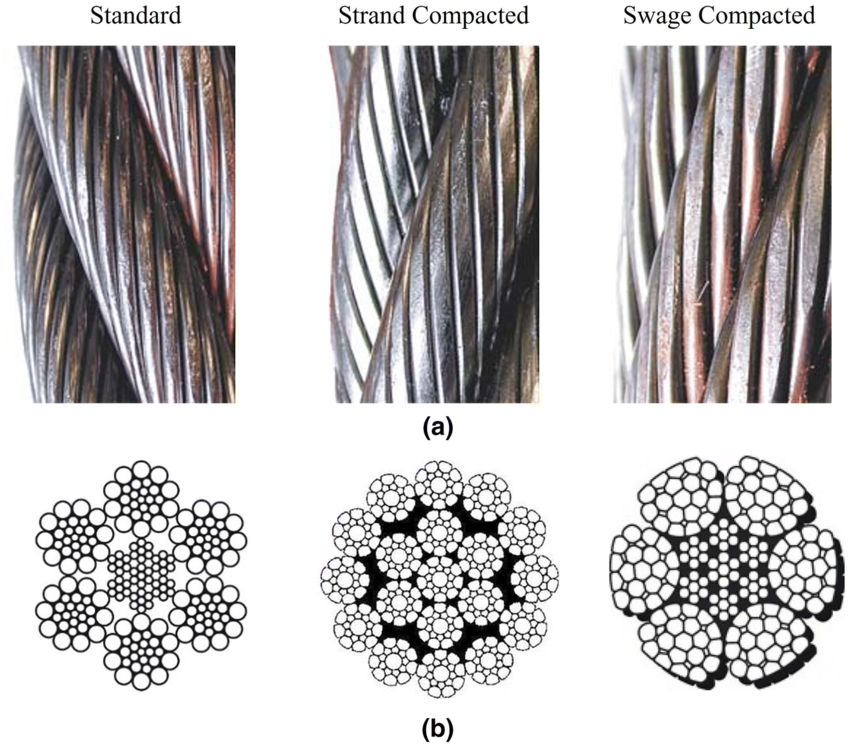

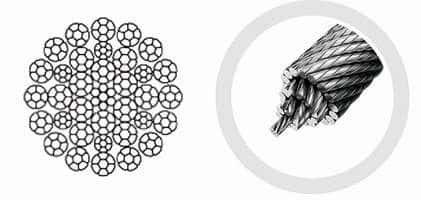

A compacted wire rope is a special rope whose outer strands are compressed using rollers or a die. This process creates a smoother, denser surface and increases the rope’s metallic area compared to standard ropes.

I remember a client from Australia who was tired of replacing his crane ropes. His questions made me realize just how important this technology is. So let’s explore what makes these ropes different and why they are so effective.

How is a compacted wire rope manufactured?

You might wonder what makes this rope so different. It all begins with a special manufacturing process. Let’s see how it’s done in the factory.

The manufacturing involves two main methods. Either individual strands are compacted before being woven into a rope, or the finished rope itself is compacted. Both methods use high-pressure rollers or dies to flatten and densify the steel strands.

The goal of this process is to increase the amount of steel in the same rope diameter. It changes the rope from having round outer strands to having flattened, smoother outer strands. This simple change has a huge impact on performance.

Strand Compaction Process

In this method, we take each individual strand before it becomes part of the final rope. We run this strand through a compacting machine, which is usually a set of precision rollers. The rollers apply immense pressure. This pressure reshapes the outer wires of the strand from a circular shape to a more trapezoidal or flattened shape.

The result is a strand that is very dense and smooth. Then, we take these compacted strands and close them together to form the final wire rope. This is the most common method we use in our factory because it gives us great control over the final rope’s profile and density.

Rope Compaction Process

The second method is to compact the entire rope after it has been manufactured. We take a fully formed, standard wire rope and run it through a large swaging machine or a set of powerful rollers. This process flattens the surface of the entire rope at once.

It also works well, but it can sometimes put more stress on the rope’s core. We choose the method based on the rope’s final application and the specific construction the customer needs.

A Quick Comparison

| Feature | Strand Compaction | Rope Compaction |

|---|---|---|

| When it’s done | Before the strands are closed into a rope | After the rope is fully constructed |

| Equipment used | Smaller rollers or dies for each strand | Large rollers or swaging machine for the whole rope |

| Result | Excellent control over strand shape and density | Smooths the outer surface of the final rope |

| Best for | High-performance ropes requiring uniform density | General purpose compacted ropes |

Both processes work to remove the empty spaces, or voids, between the wires. This results in more steel and less air in the rope’s cross-section.

What are the main advantages of using a compacted wire rope?

So, why do we go through this extra manufacturing step? The benefits are significant. They directly impact the safety, lifespan, and performance of your equipment.

The key advantages are a longer service life, superior abrasion resistance, and a higher breaking strength for the same diameter. Its smooth surface also reduces wear on sheaves and drums, which lowers overall maintenance costs for your machinery.

I have seen ropes on port cranes last 30% longer just by switching to compacted ropes. These benefits are real and can save a business a lot of money over time. Let’s break down each advantage.

Increased Abrasion Resistance

A standard wire rope has round outer strands. These create high-pressure points where the rope touches sheaves and drums. This friction causes wear. A compacted rope has a flat, smooth outer surface. This spreads the contact area over a wider surface. Less pressure means less friction and less wear. Your rope simply lasts longer, even in tough conditions like mining or port operations.

Higher Breaking Strength

Because the compacting process squeezes more steel into the same diameter, the rope is stronger. A compacted rope has a higher metallic cross-sectional area. I often explain to clients that a 20mm compacted rope can have the same strength as a 22mm standard rope. This can be very useful when you need high strength but have limitations on rope size.

Strength Comparison Example

| Rope Diameter | Standard 6×36 Rope Breaking Load | Compacted 6×36 Rope Breaking Load | Strength Increase |

|---|---|---|---|

| 20mm | Approx. 30.5 tons | Approx. 34.2 tons | ~12% |

| 32mm | Approx. 78.2 tons | Approx. 87.5 tons | ~12% |

| 40mm | Approx. 122 tons | Approx. 137 tons | ~12% |

| Note: Values are approximate and depend on the exact steel grade and construction. |

Improved Fatigue Resistance

Fatigue is the damage that happens from the rope bending and straightening over and over again. Inside a standard rope, the round wires create internal friction when they move against each other. In a compacted rope, the shaped wires fit together more closely. There is less internal movement and friction. This means the rope can handle more bending cycles before it starts to fail, giving it better fatigue life.

Reduced Wear on Equipment

This is a benefit many people overlook. The smooth surface of a compacted rope is not just good for the rope itself. It is also much gentler on your equipment. Sheaves and drums are expensive parts of a crane or hoist. Because a compacted rope causes less wear on the grooves of these parts, they last longer. I always tell my clients to think about the total cost of ownership. The rope might cost a little more upfront, but it saves you money on other replacement parts.

How does a compacted wire rope compare to a standard wire rope?

When you are making a purchasing decision, it’s helpful to see a direct comparison. Let’s put a compacted rope side-by-side with a standard rope to see the differences clearly.

Compared to a standard rope of the same size, a compacted rope has a higher breaking load, better wear resistance, and a smoother profile. However, it often comes at a higher initial purchase price, which is an important factor to consider.

The choice really depends on the application. For a simple lifting task that you only do occasionally, a standard rope might be fine. But for a hard-working crane that runs all day, the advantages of a compacted rope become very clear. I always advise looking at long-term value, not just the initial ticket price.

Detailed Feature Comparison

This table provides a direct look at the key differences between the two types of rope.

| Feature | Standard Wire Rope | Compacted Wire Rope | Why it Matters |

|---|---|---|---|

| Surface Profile | Round outer strands, “bumpy” texture | Smooth, flat outer surface | A smooth surface reduces wear on the rope and equipment (sheaves, drums). |

| Metallic Area | Lower | Higher (by 10-15%) | More steel in the same diameter means higher strength. |

| Breaking Strength (MBL) | Standard | Higher (by 10-15%) for the same diameter | You can use a smaller rope for the same load, or get more safety factor. |

| Abrasion Resistance | Good | Excellent | The rope lasts longer in environments with a lot of friction, like dragging. |

| Fatigue Life | Good | Better | The rope can withstand more bending cycles, ideal for hoisting applications. |

| Sheave/Drum Wear | Standard wear and tear | Reduced wear | Extends the life of expensive machinery components, saving money. |

| Spooling | Can have issues with crushing on multi-layer drums | Excellent spooling characteristics, resists crushing | Safer and more efficient for cranes that require long lengths of rope on a winch. |

| Initial Cost | Lower | Higher | The upfront investment is more, but the Total Cost of Ownership is often lower. |

When a purchasing manager asks me about the price difference, I explain it like buying good tires for a truck. You can buy the cheap ones and replace them every year. Or you can invest in the better ones that last longer and give you better performance. The initial cost is higher, but the long-term value is much greater. This is especially true when you factor in the cost of downtime for changing a rope.

What are the typical applications for compacted wire ropes?

Because of their special properties, these ropes excel in demanding jobs. You will find them being used in industries where performance, safety, and reliability are absolutely critical.

Compacted wire ropes are ideal for heavy-duty applications. This includes main hoist lines for mobile and tower cranes, mining operations, and large overhead cranes in steel mills. Their durability makes them perfect for high-usage environments.

If a rope needs to lift heavy loads all day, every day, then a compacted rope is almost always the better choice. We export these ropes to many countries for exactly these types of jobs.

Crane Operations

This is the number one application. Cranes need ropes with high strength and great fatigue resistance.

- Mobile and Crawler Cranes: The main hoist lines on these large cranes benefit from the high strength and excellent spooling of compacted ropes.

- Tower Cranes: Used in construction, these cranes operate for long hours. The long life of a compacted rope reduces the need for difficult and dangerous rope changes high in the air.

- Port and Container Cranes: These machines run almost 24/7. The abrasion resistance of compacted ropes is a huge benefit here, as is their stability.

Mining Industry

The mining environment is one of the toughest for any piece of equipment.

- Mine Hoist Ropes: Ropes used to lift workers and materials from deep underground must be incredibly reliable. The high breaking strength and fatigue resistance are essential for safety.

- Dragline Ropes and Shovel Ropes: These ropes are dragged through rock and dirt, so abrasion resistance is the most important factor. Compacted ropes perform exceptionally well here.

Piling and Drilling Rigs

In foundation work and drilling, the ropes are subjected to high shock loads and very abrasive conditions. A compacted rope’s dense structure helps it resist crushing and damage. Its strength is also vital for lifting heavy piling hammers and drill casings.

Specialized Lifting and Industrial Use

Sometimes, an application has unique requirements.

- Overhead Gantry Cranes: In places like steel mills or heavy manufacturing plants, these cranes are constantly in use. A long-lasting rope means less production downtime.

- Offshore Applications: For some marine uses, a compacted, galvanized rope provides both strength and corrosion resistance. When our clients need BV or DNV certificates for offshore use, we often recommend this type.

What should you look for when choosing a compacted wire rope supplier?

Choosing the right rope is only half the battle. Your supplier is just as important. A good partner ensures you get the quality you pay for and the technical support you need.

Look for a supplier with proven manufacturing experience, strict quality control, and the ability to provide necessary certifications like EN 12385, ISO 9001, and third-party inspections (BV, ABS, DNV). Good communication and technical support are also key.

Over the years, I’ve learned that trust is built on consistency and transparency. When a client from Canada or Russia places an order, they need to know that the rope they receive is exactly what they specified.

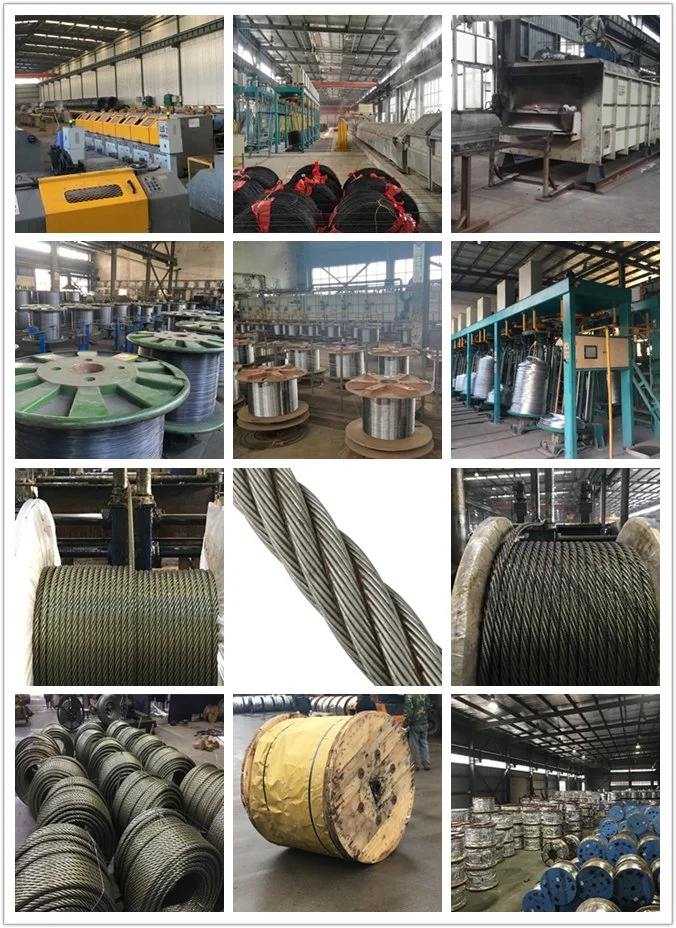

Manufacturing Capability and Experience

The process of compacting a wire rope requires precision machinery and expertise.

- Check their Factory: Does the supplier manufacture the ropes themselves or are they just a trader? A true manufacturer has control over the quality from raw material to finished product. For example, our factory has 10 production lines, so we control every step.

- Ask about their Machines: Do they use modern compacting rollers or older dies? This can affect the consistency of the final product.

Quality Control and Certification

This is non-negotiable, especially for critical applications.

- Ask for Quality System Certificates: At a minimum, they should have an ISO 9001 certificate. This shows they have a documented quality management system.

- Ask for Product Type Certificates: The rope should comply with international standards. EN 12385-4 is a common one for crane ropes.

- Ask for Third-Party Inspection: Serious buyers, especially those I work with in Australia and the UAE, often require a third-party certificate for their specific order. A good supplier will welcome this. We regularly provide certificates from agencies like BV, ABS, DNV, and RMRS.

Key Certifications to Know

| Certificate | What it Means | Why it’s Important |

|---|---|---|

| ISO 9001 | The company has a certified Quality Management System. | Shows they have processes for ensuring consistent quality. |

| EN 12385-4 | The rope meets the European standard for steel wire ropes for general lifting applications. | A key benchmark for crane rope quality and safety. |

| API 9A | The rope meets the American Petroleum Institute’s standards, often for oil and gas. | Essential for applications in the energy sector. |

| BV, DNV, ABS, RMRS | Certificates from classification societies (Bureau Veritas, DNV, American Bureau of Shipping, etc.). | Often required for marine, offshore, and other high-stakes projects. Proves the product was inspected by a trusted third party. |

Technical Expertise and Support

Your supplier should be more than just an order taker. They should be a partner. Can they help you select the right rope construction for your specific crane? Do they understand the difference between a rope for a mobile crane versus a tower crane? I often spend time on calls with clients to ensure they are getting the perfect rope, not just an “off-the-shelf” solution. This technical support is a huge part of the value.

Conclusion

Compacted wire ropes offer superior strength, a longer lifespan, and better performance for demanding jobs. Choosing the right rope is a critical investment in your safety and efficiency.