Are you tired of wire ropes failing in your demanding jobs? Finding the right one can feel like a puzzle.

The strongest wire rope is typically made of high-tensile steel, has a larger diameter, and uses a strong core like IWRC. These features give it the highest breaking strength.

Let’s simplify this. We need to know what makes a wire rope tough enough for your toughest tasks. I’ll explain it clearly.

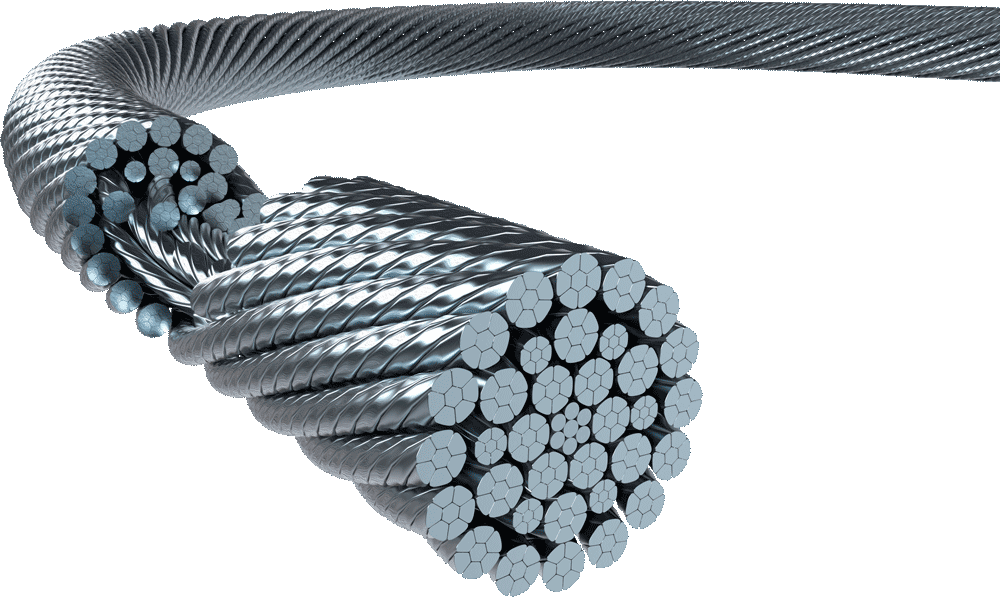

How Does Wire Rope Construction Influence Its Strength?

Have you ever wondered what goes into making a wire rope so strong? It’s all in how it’s put together.

The way a wire rope is built—how many wires it has, how those wires are grouped, and what’s in the middle—greatly affects its strength.

Understanding these details helps you pick the best rope. We’ll look at different designs and what makes them strong.

What Are the Basic Parts of a Wire Rope?

First, let’s know the main components.

- Wires: These are the individual metal strands.

- Strands: Wires are twisted together to form strands.

- Core: This is the center support of the rope.

- Lay: This is how the strands are twisted around the core.

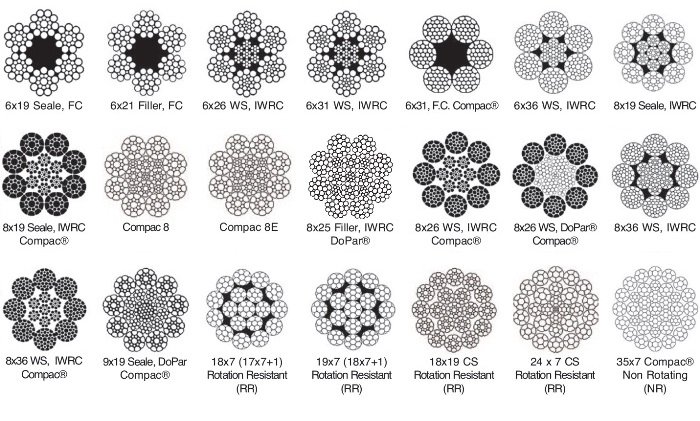

How Do the Number of Wires and Strands Matter?

More wires can mean more flexibility, but fewer, thicker wires often mean more strength.

| Rope Type | What it’s made of | How strong is it? |

|---|---|---|

| 6×7 | 6 strands, 7 wires each | Okay strength, flexible |

| 6×19 | 6 strands, 19 wires each | Good mix of strength and flexibility |

| 6×37 | 6 strands, 37 wires each | Very flexible, for special uses |

| 8×19 | 8 strands, 19 wires each | More flexible, good for lifting |

| 19×7 | 19 strands, 7 wires each | Very flexible, lasts longer |

| Compacted | Wires are pressed tight | Much stronger, resists wear better |

Why is the Core Important for Strength?

The core is like the skeleton of the rope.

- Fiber Core (FC): Made of fiber. It’s flexible but not as strong as a steel core. It can also be damaged by heat or crushing.

- Independent Wire Rope Core (IWRC): This core is a rope itself. It makes the entire wire rope much stronger. It also resists crushing and heat better. For best strength, choose IWRC.

What Kind of Metal is the Strongest for Wire Ropes?

The material itself makes a big difference. What metal performs the best?

High-tensile steel is the strongest metal for wire ropes. It can handle very heavy loads without breaking.

We need materials that can take a lot of force. Steel is excellent for this.

Different Types of Steel

Not all steel is the same. Some steel is made to be stronger.

- Carbon Steel: Common, but strength varies.

- Alloy Steel: This steel has extra metals added. This makes it much stronger and better at resisting wear and rust.

Does Coating the Rope Help Strength?

Protective coatings are important, but do they affect strength?

- Galvanization: This is a zinc coating to stop rust. It helps the rope last longer. However, it slightly reduces the rope’s breaking strength.

- Plastic Impregnation: Some fiber cores are filled with plastic. This makes them more stable and resistant to water. Most strong ropes use IWRC, sometimes with plastic.

What Wire Rope Classifications Mean for Strength?

There are many ways to classify wire ropes. How do we know which ones are the strongest?

Look for wire ropes with high tensile strength numbers. Also, choose ropes with specific strong constructions like compacted ropes or those using an IWRC core.

We must match the rope’s rating to the job’s needs. Let’s understand the labels.

Understanding Tensile Strength Numbers

Tensile strength tells you how much force a rope can handle before breaking. It’s usually in psi or MPa.

A higher tensile strength number means a stronger rope.

Understanding Industry Standards

Standards help ensure quality and safety.

- EN 12385-4: This European standard is for lifting ropes. Ropes meeting this are reliable and strong.

- API: Standards for oil and gas often require very strong ropes.

Other Important Factors Besides Strength

While strength is key, other features help the rope last.

- Wear Resistance: How well it handles rubbing against things.

- Flexibility: How easily it bends without breaking.

- Rust Resistance: How well it stays free from rust.

For the toughest jobs, you need a rope that is strong and also resists wear and lasts a long time. Compacted wire ropes are a good example as they are strong and resist wear well.

Can We Make Custom Ropes That Are Stronger?

Sometimes standard ropes aren’t enough. Can we build a super-strong rope?

Yes, we can create custom wire ropes by choosing special materials, stronger designs, and better cores for specific, tough jobs.

We can build a rope exactly for your needs. This means picking the best materials for every part.

Choosing the Best Materials

We can use the strongest steel available.

- Stronger Steel Types: Selecting steel with the highest possible strength ratings.

- Special Coatings: Using advanced coatings for better protection.

Designing for Heavy Loads

We can change how the rope is made.

- Thicker Wires: Using wires that are a bit thicker.

- More Strands: Using more strands to spread the load.

- Tight Compaction: Using special machines to make the rope denser and stronger.

The Best Core Choice

The core is vital for extreme strength.

- Better Cores: Looking at advanced synthetic cores or strong steel cores.

- Plastic Inside: Making sure the core is protected and stable.

Conclusion

The strongest wire rope uses strong steel, a good design, and a solid core for maximum power.