Mining lifts fail when ropes wear out too fast. Safety and efficiency are always at risk in these situations.

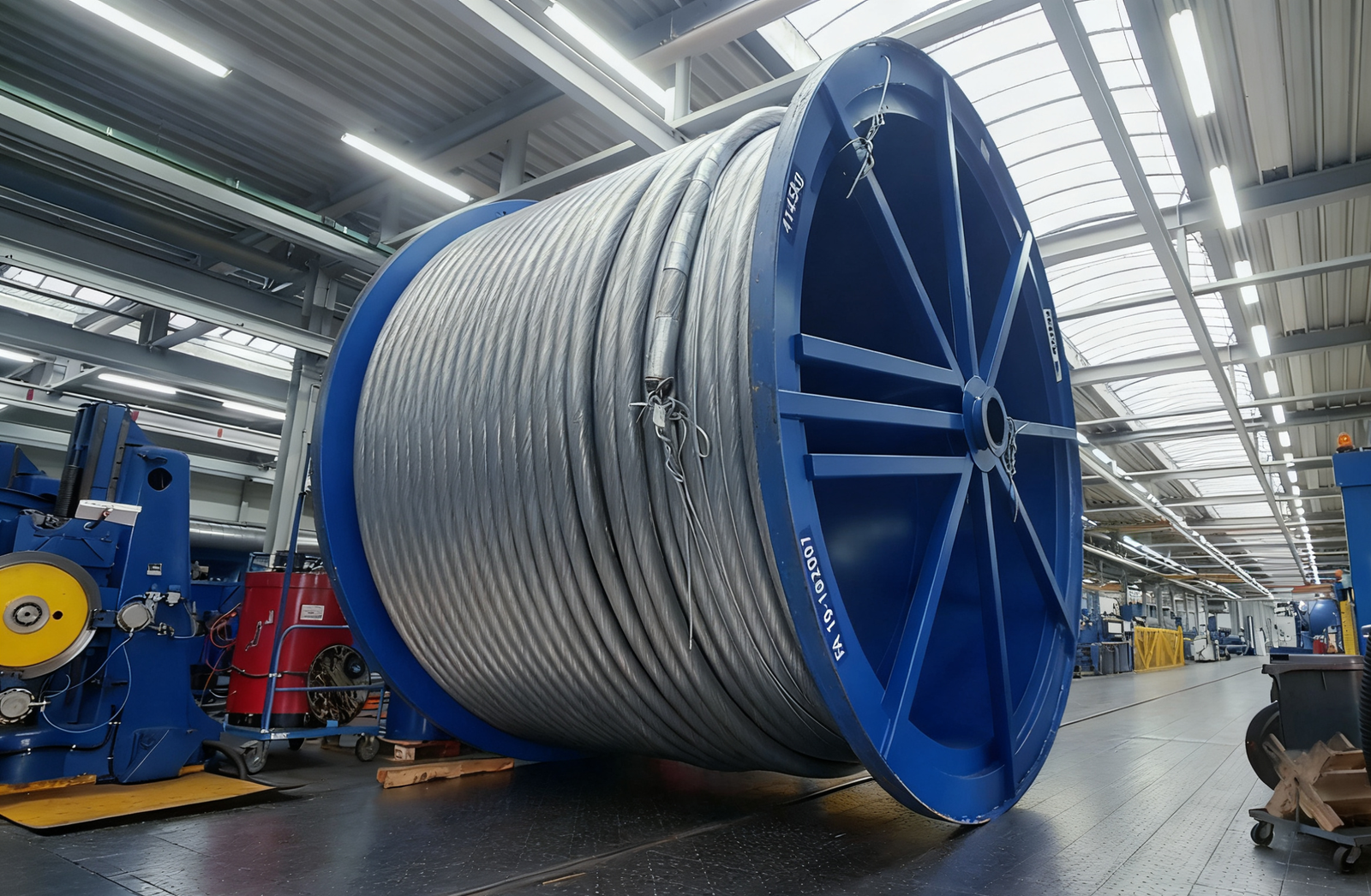

Friction winder wire ropes are designed to provide high flexibility, strong tensile strength, and superior performance, ensuring safe and efficient hoisting in mining operations.

I’ve seen projects where using the wrong rope caused downtime. Switching to friction winder ropes solved these problems almost immediately.

How Do Friction Winder Ropes Work in Mining?

These ropes operate in pairs, sets of four or six, and rely on proper lubrication to ensure safety and long service life. Almost all rope constructions can be used, from six strand round to full locked coil ropes.

Rope Types and Their Applications

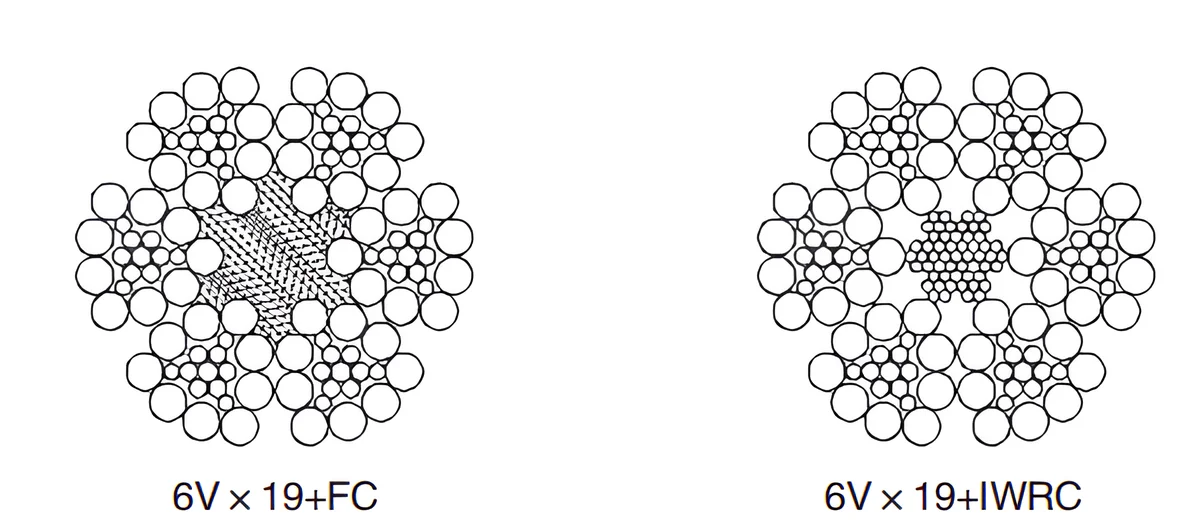

Friction winder ropes come in several constructions:

| Rope Type | Core | Typical Use |

|---|---|---|

| Six strand round | Natural or synthetic fibre | Standard friction hoisting |

| Six strand triangular | Fibre core (FC) | Heavy load friction hoisting |

| Rotation resistant | IWRC | Minimizes twisting |

| Full locked coil | Steel core | High-load and long travel |

I remember a mining site where we switched from standard round strand ropes to rotation-resistant ropes. The difference was immediate—less rope twist and smoother operation. Proper lubrication is essential to reduce wear, fatigue, and prevent rope failure.

Why Set Configurations Matter

Friction winder ropes are never used alone. They are always in sets of 2, 4, or 6. Using multiple ropes distributes the load evenly. On one project, a four-rope setup avoided slippage and reduced downtime compared to older two-rope systems.

Safety Considerations

Ropes must be checked daily for wear, broken wires, and corrosion. Lubrication schedules are critical. Using certified ropes compliant with EN12385-4 ensures performance standards and safety. Even a small oversight in inspection can cause serious accidents in mining lifts.

How to Choose the Right Friction Winder Rope for Your Mine?

High tensile strength, lubrication compatibility, and rope construction are key factors. Customizable solutions can meet specific mining requirements while ensuring compliance with BV, CE, DNV, ABS, or RMRS certifications.

Matching Rope to Application

| Mining Type | Recommended Rope | Key Feature |

|---|---|---|

| Vertical shaft | Six strand round | Flexible and durable |

| Inclined shaft | Six strand triangular | High grip, fibre core |

| Heavy load lifts | Full locked coil | Minimal elongation |

| High-speed lifts | Rotation resistant | Reduced rotation |

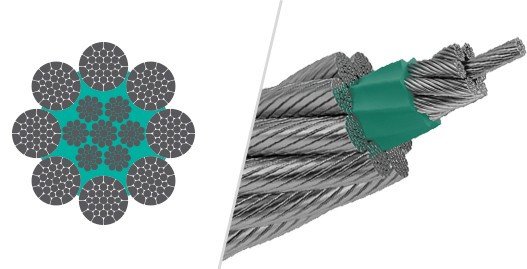

Environmental factors like temperature, moisture, and dust also affect rope choice. For instance, galvanized or plastic impregnated ropes resist corrosion better in wet mines. I once saw a rope last twice as long simply because we switched to plastic-impregnated lubrication.

Maintenance Tips for Long Rope Life

- Inspect ropes daily for broken strands and corrosion.

- Lubricate ropes regularly to reduce wear.

- Replace worn ropes promptly to prevent downtime.

- Store ropes properly when not in use to avoid deformation.

- Record all inspections and maintenance in a logbook.

Proper maintenance increases safety, reduces unexpected downtime, and extends rope life. I usually train the site team to check ropes weekly in addition to daily inspections.

What Advantages Do Aulone Friction Winder Ropes Offer?

Our friction winder ropes provide improved flexibility, high tensile strength, and superior performance. They are suitable for all common rope constructions and can be customized with logos or certified by BV, CE, DNV, ABS, or RMRS.

Features That Make a Difference

| Feature | Benefit |

|---|---|

| High tensile strength | Supports heavy loads safely |

| EN12385-4 compliance | Meets international standards |

| Customizable logo | Easy identification |

| Plastic Impregnated / Galvanized | Long-term corrosion resistance |

| Suitable for all constructions | Versatile applications |

Aulone ropes are versatile. They can work in high-speed lifts, heavy load applications, or standard operations. Proper setup with correct lubrication maximizes their lifespan. On one site, switching to our full locked coil ropes improved lift efficiency by 15%.

Lubrication reduces friction, prevents wear, controls dust, and extends rope life. In mining, consistent lubrication routines improve safety and efficiency.

At a mine in Indonesia, the client used old ropes that wore out quickly. We supplied six-strand triangular ropes with fibre cores and proper lubrication. The ropes lasted two years longer than previous installations. The client noticed smoother lifts and fewer maintenance interruptions.

Many clients require specific certifications for mining operations. Aulone ropes can come with BV, CE, DNV, ABS, or RMRS certificates. Logos can also be added for easy identification. Customization ensures clients meet legal and operational standards while enhancing rope management.

Practical Tips for Maximizing Rope Life

Simple steps can prevent rope wear and improve safety.

Snippet paragraph: Regular inspections, proper lubrication, correct tension, and appropriate rope selection help friction winder ropes last longer and perform better in mining operations.

Daily and Weekly Maintenance

| Tip | Action | Benefit |

|---|---|---|

| Daily visual check | Inspect for broken wires, corrosion, or deformation | Prevents accidents |

| Weekly rope cleaning | Remove dust, mud, and debris | Reduces wear |

| Lubrication | Apply recommended lubricants | Minimizes friction and extends rope life |

| Correct tension | Adjust tension based on load and travel height | Prevents rope slip |

| Proper storage | Coil ropes without sharp bends | Avoids deformation |

I personally recommend logging every inspection and maintenance step. This habit helps identify patterns of wear and plan timely replacements.

Choosing the Right Lubricant

- Fibre core ropes benefit from penetrating lubricants.

- Steel core ropes need corrosion-resistant oils.

- Plastic impregnated ropes require minimal extra lubrication.

Using the wrong lubricant can reduce rope life and increase maintenance costs.

Installation Tips

- Always use sets of 2, 4, or 6 ropes.

- Make sure the ropes are properly aligned on pulleys and drums.

- Avoid sudden starts or stops, which increase stress.

These simple steps reduce downtime and prevent costly replacements.

Frequently Asked Questions (FAQ)

1. Can all rope constructions be used for friction winders?

Yes. With the right lubrication, almost all constructions—six strand round, six strand triangular, rotation resistant, and full locked coil—can be used safely in friction hoisting applications.

2. How often should friction winder ropes be replaced?

Rope life depends on load, speed, environment, and maintenance. Daily inspections and proper lubrication extend service life. Replace ropes as soon as visible wear or broken wires exceed safety limits.

3. Why are friction winder ropes used in sets?

Using sets of 2, 4, or 6 distributes load evenly, reduces rope slip, and improves safety. Single ropes are not suitable for mining hoisting.

4. What certifications are available for Aulone ropes?

Aulone ropes can be certified by BV, CE, DNV, ABS, or RMRS. This ensures compliance with international standards and provides assurance for high-stakes mining operations.

5. Can ropes be customized?

Yes. Logos, specific rope lengths, or even special coatings like galvanized or plastic impregnated can be customized. This is useful for inventory management and meeting specific site requirements.

6. How important is lubrication?

Lubrication reduces friction, prevents corrosion, and extends rope life. Neglecting lubrication is one of the main causes of rope failure in mining applications.

Conclusion

Proper rope selection, maintenance, lubrication, and certification ensure friction winder ropes perform safely and efficiently. Following practical tips and addressing common questions prevents downtime and enhances mining productivity.