Mining operations face extreme stress on equipment, and rope failure can halt production fast. I’ve personally seen delays that cost thousands of dollars per hour.

The right mining wire ropes provide high tensile strength, abrasion resistance, and long service life, keeping shovels and draglines running smoothly.

I remember a mine site where using the wrong rope caused repeated downtime. That experience made me realize how critical the right rope selection is. Let’s explore why EP8XK36WS-IWRC and EP6XK36WS-IWRC are trusted worldwide.

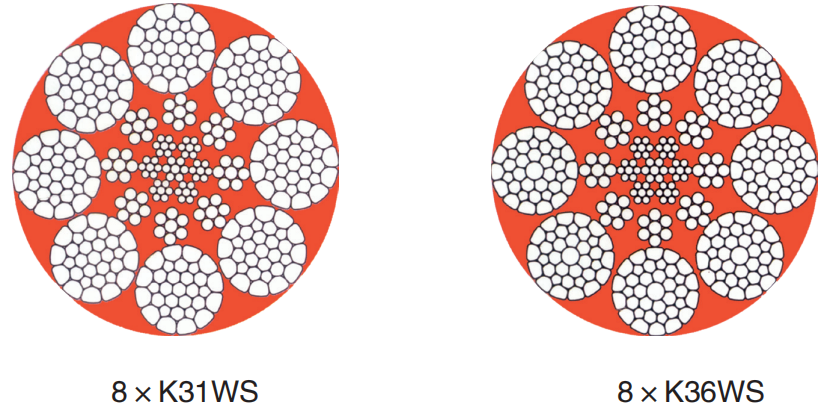

Why is EP8XK36WS-IWRC widely used in dragline and shovel applications?

EP8XK36WS-IWRC is an eight-stranded fully plasticated wire rope. Its design prevents drum wear, provides crush resistance, and ensures reliability in surface mining operations.

The EP8XK36WS-IWRC balances strength, flexibility, and durability. Its full plastic impregnation cushions the strands, keeping internal stress low and preventing dirt from entering.

| Feature | Benefit |

|---|---|

| Fully plastic impregnated | Reduces internal friction and extends rope life |

| 8-strand construction | Handles heavy loads and bending fatigue |

| Surface mining design | Ideal for dragline and shovel hoist operations |

| Crush resistance | Protects rope from external pressure and drum deformation |

This rope excels in hoist applications. The plastic filling distributes stress evenly. I’ve seen operators run EP8XK36WS-IWRC for months without replacing it, whereas unplasticated ropes fail much faster.

Practical applications:

- Dragline hoist ropes: Large draglines experience bending and crushing. EP8XK36WS-IWRC absorbs the stress efficiently.

- Shovel hoist ropes: In shovel operations, constant tension and load cycles can damage ropes quickly. EP8XK36WS-IWRC resists wear and maintains performance.

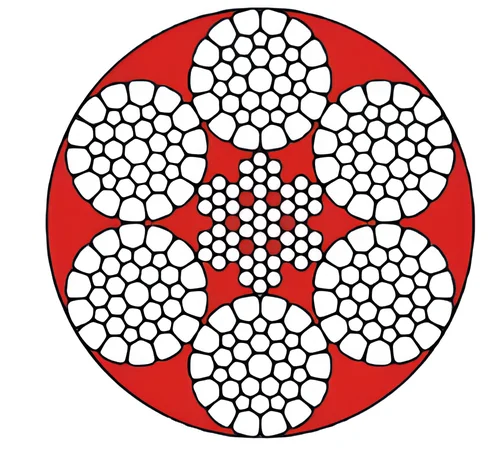

How does EP6XK36WS-IWRC improve performance for electric shovels?

EP6XK36WS-IWRC is a six-strand plastic coated rope offering excellent wear resistance, reduced friction, and improved fatigue life for shovel hoists in open-pit mining.

The six-strand design is compacted for strength. Plastic impregnation cushions the strands and keeps internal lubricant in place. It reduces rope friction and drum wear, which is crucial in electric shovel operations.

| Structure | Application | Advantage |

|---|---|---|

| 6xK36WS-IWRC | Electric shovel hoist (WK, P & H, EKG, BE series) | Excellent fatigue resistance |

| EP6XK36WS-IWRC | Open-pit iron, coal, copper mines | Reduced stress with wheeltrain |

| 6xK41WS-EPIWRC | Construction & other mining | Superior abrasion resistance |

This rope distributes internal stress, prevents strand damage, and keeps shovels running longer. I’ve visited mines where switching to EP6XK36WS-IWRC reduced downtime by 30%.

Typical uses:

- Open-pit coal mining: Hoist ropes face repeated bending and heavy loads. EP6XK36WS-IWRC performs consistently.

- Iron ore operations: Heavy abrasive material requires ropes that maintain integrity. Six-strand compacted design helps.

- Copper mining: Corrosive environments benefit from plasticated protection.

What advantages do plastic impregnated ropes provide in mining?

Plastic impregnated ropes protect ropes and machinery from excessive wear and improve operational life.

Plastic filling reduces internal friction, keeps dirt out, cushions strands, and extends rope life, improving efficiency and safety.

Plastic impregnation is not just a technical term. I’ve seen operators notice immediate benefits after switching.

- Lubricant retention: Internal movement between wires stays smooth.

- Drum and sheave protection: Reduced wear extends equipment life.

- Improved bending fatigue life: Ropes bend over drums without breaking strands.

- Consistent performance: Even under heavy load and harsh conditions.

| Feature | Why it matters |

|---|---|

| Plastic polymer | Cushions strands, keeps out dirt |

| Lubricant retention | Reduces internal wear |

| Crush resistance | Extends drum and rope life |

Mines that adopt plasticated ropes report fewer accidents, less maintenance, and longer rope intervals. For me, this is the most tangible advantage—saving both money and stress on-site.

How to select the right mining rope for shovel applications?

Choosing the right rope depends on load, environment, and hoist type. The wrong choice can be costly and dangerous.

Select ropes based on load, abrasion, fatigue resistance, and drum compatibility. EP6XK36WS-IWRC and EP8XK36WS-IWRC cover most surface mining shovel needs.

Choosing the rope is more than picking the biggest or strongest one. Consider:

- Hoist type: Dragline or shovel?

- Mining material: Coal, iron ore, copper?

- Environmental conditions: Abrasive, wet, dusty?

- Rope construction: Strand count, plastication, compacted or standard?

| Rope Type | Best Use | Key Benefit |

|---|---|---|

| EP8XK36WS-IWRC | Dragline hoist | Crush resistance and durability |

| EP6XK36WS-IWRC | Shovel hoist | Fatigue and abrasion resistance |

| 6xK41WS-EPIWRC | Electric shovels | Wear and impact resistance |

By matching rope features to site conditions, I’ve helped mining teams cut downtime, maintain production, and reduce maintenance cost. Certifications like BV, CE, or ABS confirm quality and safety.

Selecting for your site:

- Assess load cycles: High cycles need fatigue-resistant ropes.

- Check abrasion exposure: Plasticated ropes protect better in abrasive environments.

- Verify compliance: Certificates ensure rope quality meets standards.

- Consider maintenance: Lubrication retention and strand cushioning reduce upkeep.

When I visit a new mine, I always ask these questions first. It helps select the rope that delivers long-term reliability.

Conclusion

Mining wire ropes like EP8XK36WS-IWRC and EP6XK36WS-IWRC deliver durability, safety, and performance for shovels and draglines. Choosing the right rope keeps operations efficient and safe.