Mining operations face extreme conditions every day. Low-quality ropes can break, delay projects, and risk lives. How can premium ropes solve this?

Premium ropes offer high strength, long lifespan, and safety compliance for mining, reducing accidents and operational delays effectively.

Every mine I’ve visited had the same story: cheap ropes fail too soon. I realized quality ropes aren’t just a cost—they are a safeguard for people and productivity.

How do mining ropes differ from standard ropes?

Mining ropes face heavy loads, abrasive surfaces, and harsh chemicals. Not every rope can survive.

Mining ropes are designed with reinforced cores, protective coatings, and high breaking strength to handle extreme environments safely.

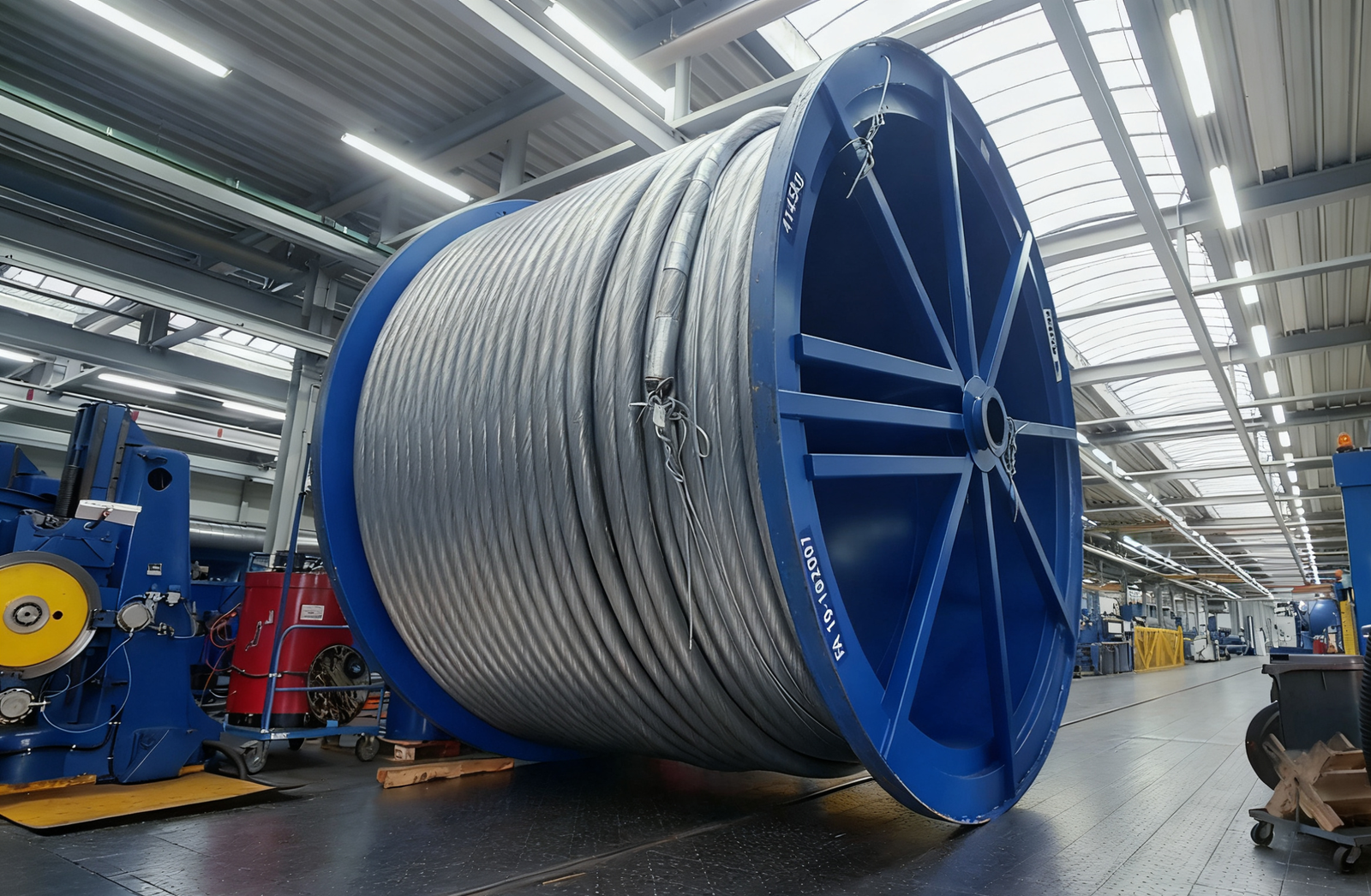

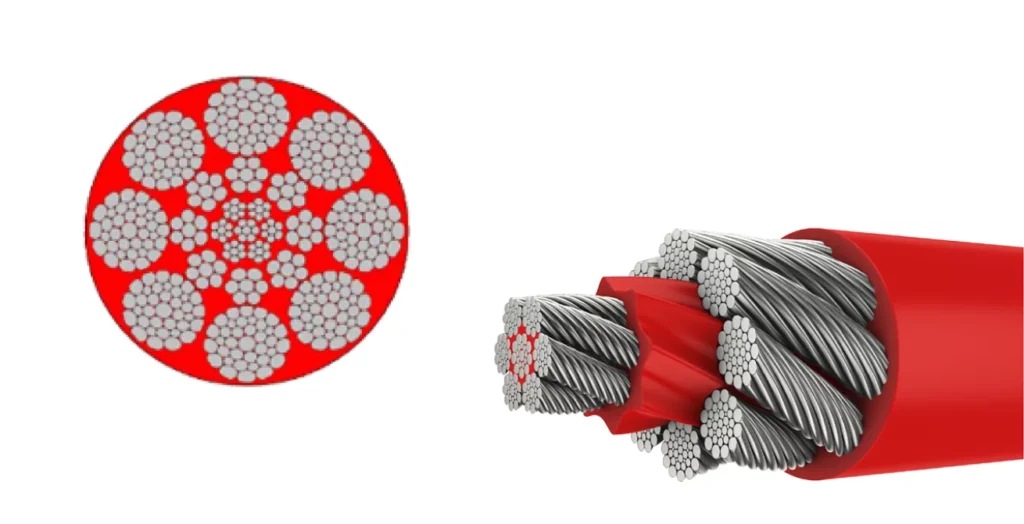

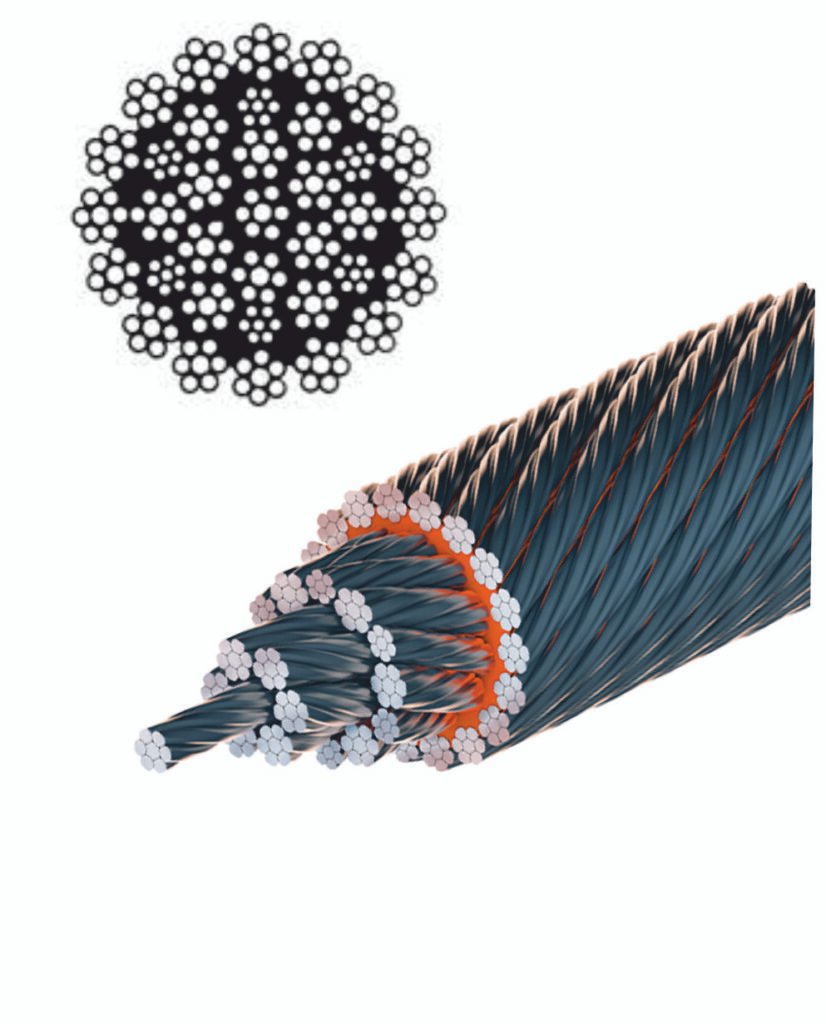

Dive Deeper into mining rope construction

Mining ropes often use multiple layers. The inner core carries the load while the outer strands resist abrasion.

| Feature | Description | Benefit |

|---|---|---|

| Core | Fiber or steel | Supports weight, adds flexibility |

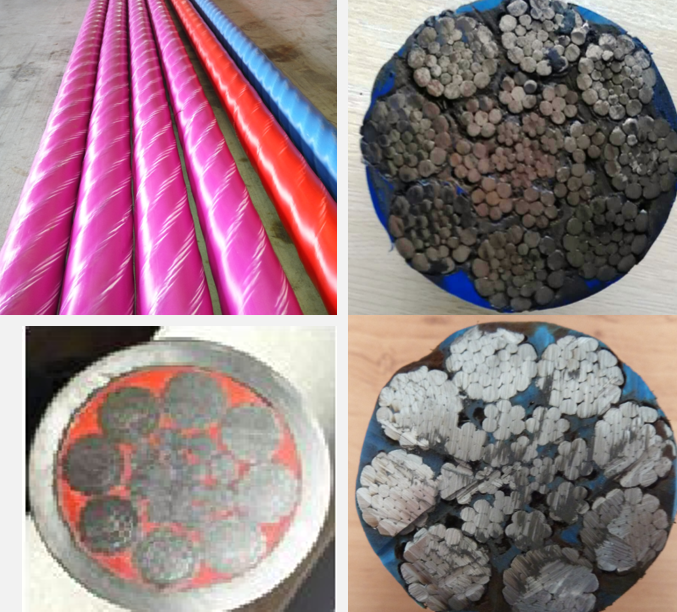

| Outer layer | Galvanized or plastic coated | Resists wear and corrosion |

| Strand design | Compact or round strands | Reduces friction, increases durability |

Some ropes also use plastic impregnation. This keeps lubrication inside and protects against dirt and moisture. I’ve seen ropes last twice as long this way.

What makes a rope suitable for mining?

Not all ropes survive mining conditions. Choosing the right rope requires careful attention.

A suitable mining rope must have high tensile strength, EN12385-4 compliance, and resistance to abrasion, corrosion, and twisting.

Dive Deeper: Key specifications to check

- Breaking load – must exceed expected operational load with margin.

- Tensile strength – high steel quality ensures fewer failures.

- Coating – galvanization or plastic prevents corrosion in wet environments.

- Rotation resistance – prevents ropes from twisting under load.

| Specification | Importance | Recommended Value |

|---|---|---|

| Breaking load | Safety | ≥ operational load × 1.5 |

| Tensile strength | Durability | High-carbon steel |

| Coating | Lifespan | Galvanized / plastic |

| Rotation resistance | Safety | Non-rotating design |

I’ve observed that cutting corners on these specs often leads to costly downtime and replacement costs.

How do premium ropes improve safety and productivity in mining?

Safety incidents often start with rope failures. Premium ropes can prevent accidents.

Premium ropes reduce the chance of accidents, support heavier loads, and allow continuous operation, improving overall productivity.

Dive Deeper: Real-world impact

High-quality ropes let crews operate confidently, especially with cranes, draglines, and hoists. When ropes are consistent, schedules stay on track.

| Impact Area | Benefit | Example |

|---|---|---|

| Safety | Fewer rope breaks | Reduced worker injuries |

| Efficiency | Faster operations | Less downtime for rope replacement |

| Cost | Lower long-term expenses | Fewer frequent purchases |

From my experience, mining companies often save more in the long run by investing upfront in premium ropes. It’s a clear trade-off between short-term cost and long-term reliability.

What types of premium ropes are best for mining operations?

Mining uses different ropes for hoists, shovels, and draglines. Each has specific needs.

Steel wire ropes, plastic impregnated ropes, and galvanized ropes are ideal, providing strength, corrosion resistance, and long-term reliability.

Dive Deeper: Choosing rope types

| Rope Type | Use Case | Advantages |

|---|---|---|

| Steel wire rope | Hoists, elevators | High tensile strength, long lifespan |

| Plastic impregnated | Draglines | Resists abrasion and contamination |

| Galvanized | Outdoor mining | Corrosion protection, durability |

I often advise clients to match rope type to equipment and environment. One wrong choice can cut rope life in half.

How can you maintain mining ropes for longer life?

Maintenance is just as important as rope quality. Regular checks prevent surprises.

Inspect ropes for broken wires, corrosion, and wear. Lubricate and replace damaged ropes to extend life and ensure safety.

Dive Deeper: Maintenance tips

- Visual inspections weekly for cracks or frays.

- Lubrication for internal strands to reduce friction.

- Follow EN12385-4 guidelines for service limits.

- Replace ropes showing excessive wear immediately.

| Maintenance Task | Frequency | Reason |

|---|---|---|

| Visual inspection | Weekly | Detect early damage |

| Lubrication | Monthly | Reduce friction |

| Load testing | Biannually | Ensure strength |

| Replacement | As needed | Safety compliance |

I’ve seen well-maintained ropes last 50% longer than neglected ones. Safety and cost savings go hand in hand.

Conclusion

Premium mining ropes ensure safety, reliability, and productivity in harsh environments. Proper choice and maintenance make all the difference.